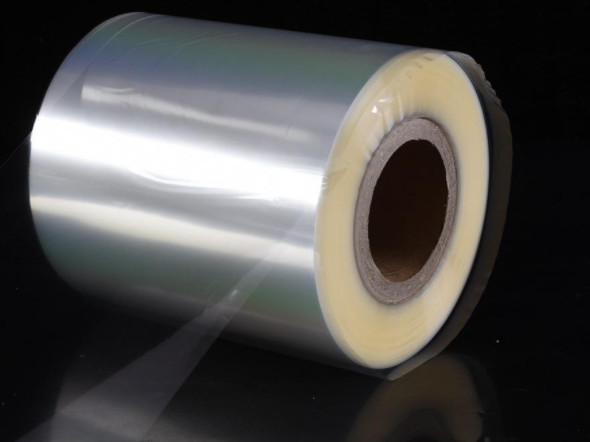

Super Slip Masterbatch

SILIKE Super-slip masterbatch has several grades with resin carrier like PE, PP, EVA, TPU..etc , contains 10%~50% UHMW Polydimethylsiloxane. A small addition of it can significantly lower the COF, improve the surface smoothness without any bleeding. Suitable for BOPP, CPP, BOPET, EVA, TPU film....

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9300 | Off-white pellet | -- | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9200 | Off-white pellet | -- | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9100 | Off-white pellet | Silicone Wax | -- | -- | 300-100ppm | PE films,Pipes,Wires |

| Super Slip Masterbatch SILIMER 5065HB | White or off-white pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER 5064MB2 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PE |

| Super Slip Masterbatch SILIMER 5064MB1 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PE |

| Slip Silicone Masterbatch SILIMER 5065 | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP/PE |

| Slip Silicone Masterbatch SILIMER 5064A | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PP/PE |

| Slip Silicone Masterbatch SILIMER 5064 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PP/PE |

| Slip Silicone Masterbatch SILIMER 5063A | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Slip Silicone Masterbatch SILIMER 5063 | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Slip Silicone Masterbatch SILIMER 5062 | white or light yellow pellet | Siloxane polymer | -- | LDPE | 0.5~6% | PE |

| Slip Silicone Masterbatch FA112R | White or off-white pellet | Siloxane polymer | -- | Co-polymer PP | 2~8 | BOPP/CPP |

| Slip Silicone Masterbatch SF110 | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Slip Silicone Masterbatch SF105D | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Slip Silicone Masterbatch SF105B | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF-105A | White or off-white pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Slip Silicone Masterbatch SF105 | White Pellet | Siloxane polymer | -- | PP | 5~10% | BOPP/CPP |

| Super Slip Masterbatch LYSI-401 |

White pellet | Siloxane polymer | 50% | PE | 0.2~5% | PE |

| Super Slip Masterbatch SF 109 |

White pellet | Siloxane polymer | -- | TPU | 6~10% | TPU |

| Super Slip Masterbatch LYSI-406 |

White pellet | Siloxane polymer | 50% | PP | 0.2~5% | PP |

| Super Slip Masterbatch SF 102 |

White pellet | Siloxane polymer | -- | EVA | 6~10% | EVA |

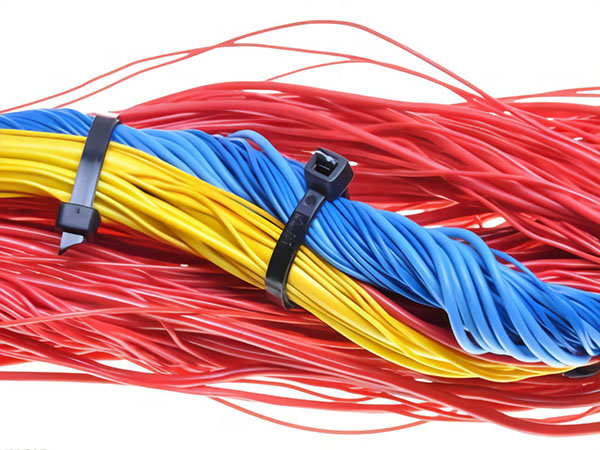

PPA MB and PFAS-free & Fluorine-free PPA

This series of product include two types, one is the traditional PPA masterbatch, and the other one is PFAS-free & fluorine-free polymer processing aids to overcome the possibility of a future ban on fluorine, grade name Silimer 5090, It can replace traditional PPA MB, with a minimal dosage can effectively improve resin fluidity and processability, reduce die drool during extrusion, improve shark skin phenomenon, and can significantly extend the screw cleaning cycle.

Currently, both types are widely used to improve plastic's lubrication and surface characteristics during plastic extrusion and suit PE films, pipes, wires, and other plastic industries, etc.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9300 | Off-white pellet | -- | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9200 | Off-white pellet | -- | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 9100 | Off-white pellet | Silicone Wax | -- | -- | 300-100ppm | PE films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 5091 | Off-white pellet | Silicone Wax | -- | PP | 0.5~10% | PP films,Pipes,Wires |

| PFAS-Free Polymer Process Aid (PPA) SILIMER 5090 | Off-white pellet | Silicone Wax | -- | LDPE | 0.5~10% | PE films,Pipes,Wires |

| Silicone-PPA Masterbatch SILIMER 5080 | Off-white pellet | Silicone Wax | -- | LLDPE | 1~5% | PE films,Pipes,Wires |