Slip Silicone Masterbatch SILIMER 5065HB For PP Films

Description

SILIMER 5065HB is a super-slip masterbatch with long chain alkyl-modified siloxane masterbatch containing antiblock additive. It is mainly used in CPP films, oriented flat film applications and other products compatible with polypropylene. It can significantly improve anti-blocking & smoothness of the film, and the lubrication during processing, can greatly reduce the film surface dynamic and static friction coefficient, make the film surface more smooth. At the same time, SILIMER 5065HB has a special structure with good compatibility with the matrix resin, no precipitation, no sticky, and no effect on the transparency of film.

Product Specifications

|

Grade |

SILIMER 5065HB |

|

Appearance |

white or off-white pellet |

|

Resin base |

PP |

|

Melt index (℃) (190℃,2.16kg)(g/10min) |

7~15 |

|

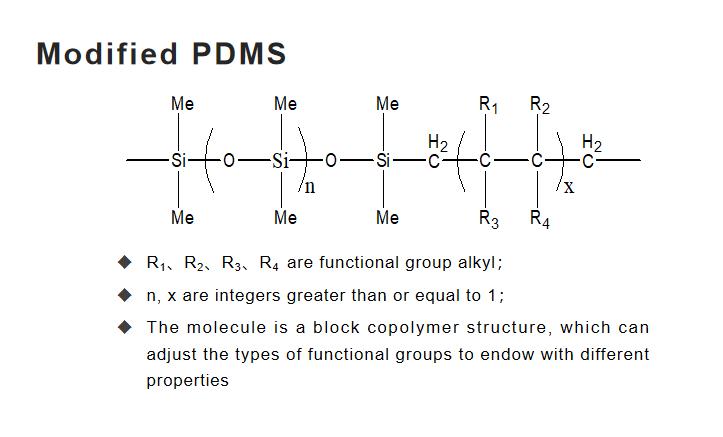

Slip additive |

Modified PDMS |

|

PDMS molecular weight Mn g/mol

|

Min 20000 |

|

PDMS molecular weight Mw g/mol |

Min 650000 |

|

Antiblock additive |

Synthetic Silica |

|

SiO2 particle size D50 MKM |

5 |

Test

5065HB Transparency test in PP film:

5065HB COF Test:

Placed in a constant temperature and humidity box at 50°C and 50% humidity to simulate a high temperature environment.

Benefits

1)Improve surface quality including no precipitation, no sticky, no effect on transparency, no effect on the surface and printing of film, lower Coefficient of friction,better surface smoothness;

2)Improve processing properties including better flow ability,faster throughput ;

3)Good anti-blocking & smoothness, lower Coefficient of friction, and better processing properties in PP film.

Transportation & Storage

This product could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with a storage temperature below 50 ° C to avoid agglomeration. The package must be well sealed after each use to prevent the product from being affected by moisture.

Package & Shelf life

The standard packaging is a craft paper bag with PE inner bag with net weight of 25kg. Original characteristics remain intact for 24 months from the production date if kept in recommend storage.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

-

Phone

-

E-mail

-

WeChat

-

Top

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur