-

Silicone additives, Scratch-resistant solutions for automotive Polypropylene (CO-PP/HO-PP ) interior materials

Automotive PP interior materials, i.e. polypropylene interior materials, are widely used in automotive interiors due to their properties such as light weight, high crystallinity, easy processing, corrosion resistance, good impact strength and electrical insulation. These materials are usually mod...Read more -

Exchange Event on Food Safety: Sustainable and Innovative Flexible Packaging Materials

Food is essential to our lives, and ensuring its safety is of utmost importance. As a critical aspect of public health, food safety has gained global attention, with food packaging playing a significant role. While packaging protects food, the materials used can sometimes migrate into the food, p...Read more -

What types of cutting-edge plastic materials and plastic additives are currently being researched and developed specifically for electric vehicles (EVs)?

With the automotive industry rapidly shifting towards hybrid and electric vehicles (HEVs and EVs), the demand for innovative plastic materials and additives is skyrocketing. As prioritize safety, efficiency, and sustainability, how can your products stay ahead of this transformative wave? Types o...Read more -

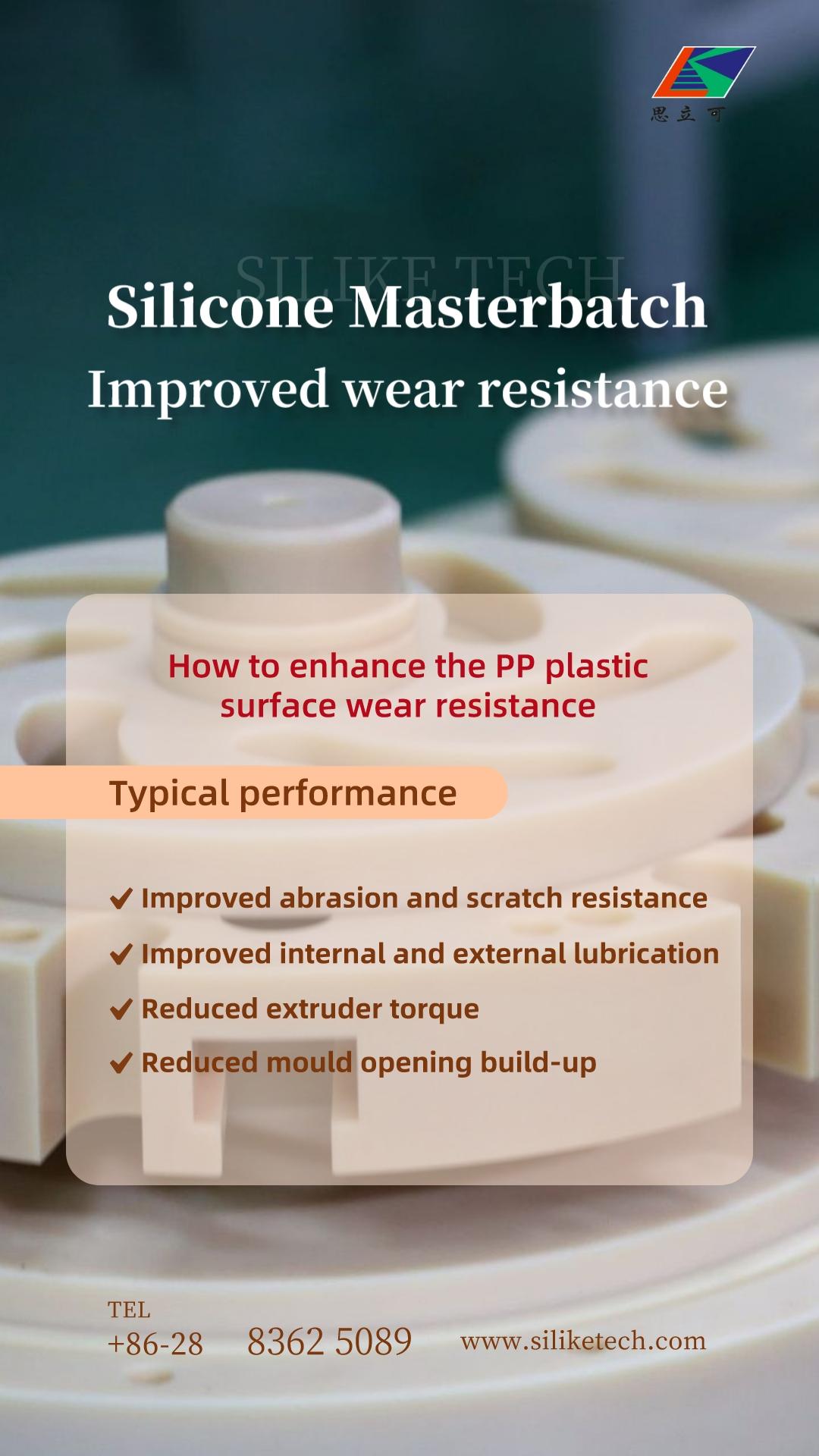

Silicone masterbatch, Plastic processing additives, widely used in automotive interiors, shoe soles, cable materials, etc.

SILIKE Silicone masterbatch is a kind of functional masterbatch with all kinds of thermoplastics as the carrier and organo-polysiloxane as the active ingredient. On the one hand, silicone masterbatch can improve the fluidity of thermoplastic resin in the molten state, improve the dispersion of fi...Read more -

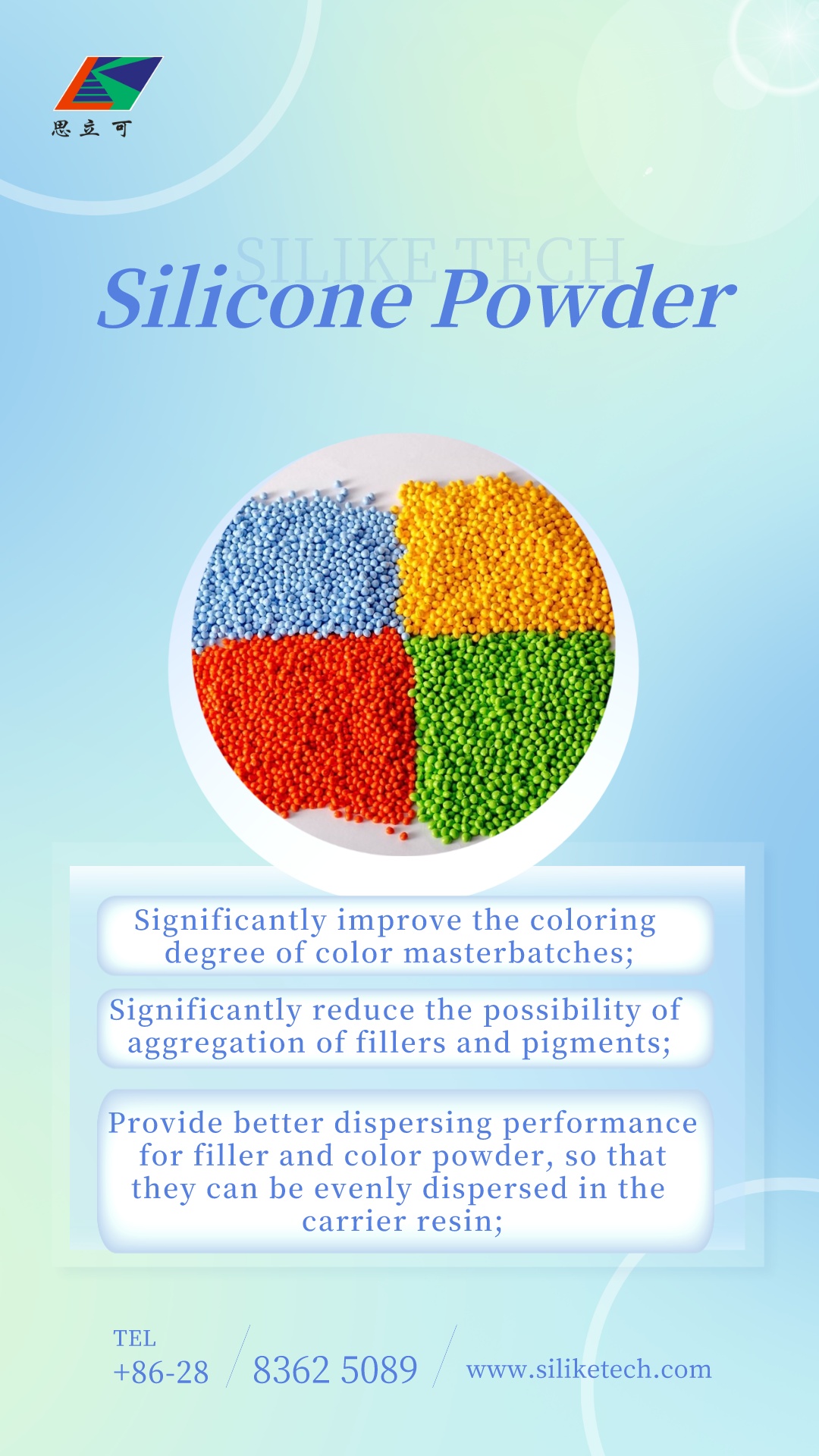

Processing Solutions for poor diffusion of the color masterbatch: silicone hyperdispersant and PFAS-Free PPA for Color Masterbatch

Color Masterbatch is a new type of special colouring agent for polymer materials, also known as pigment preparation. It consists of three basic elements: pigment or dye, carrier and additives, and is an aggregate obtained by uniformly attaching an extraordinary amount of pigment or dye to the res...Read more -

Silicone Masterbatch additives, bringing efficient and stable solutions to the TPE material processing industry

In the field of plastics processing, thermoplastic elastomers (TPEs) are widely used due to their excellent elasticity, abrasion resistance, oil resistance and recyclability. TPE materials have a wide range of applications, suitable for building materials, shoes, toys, automobiles, home appliance...Read more -

Slip agent for Metalized Cast Polypropylene Film, improve the stripping performance of the release film, reduce the stripping residue.

Metalized Cast Polypropylene Film (Metalized CPP, mCPP) not only has the characteristics of plastic film, but also replaces aluminium foil to a certain extent, playing a role in improving the product grade, and the cost is lower, in the biscuits, leisure food packaging is widely used. However, in...Read more -

Analysis of factors affecting the transparency of polypropylene cast film CPP, how to choose Slip agent that does not affect the transparency of polypropylene cast film

Polypropylene cast film (CPP film) is a kind of unstretched flat film extrusion film produced by the method of casting, which has the characteristics of good transparency, high gloss, good flatness, easy to heat sealing, etc. The surface can be used for aluminium plating, printing, compounding, e...Read more -

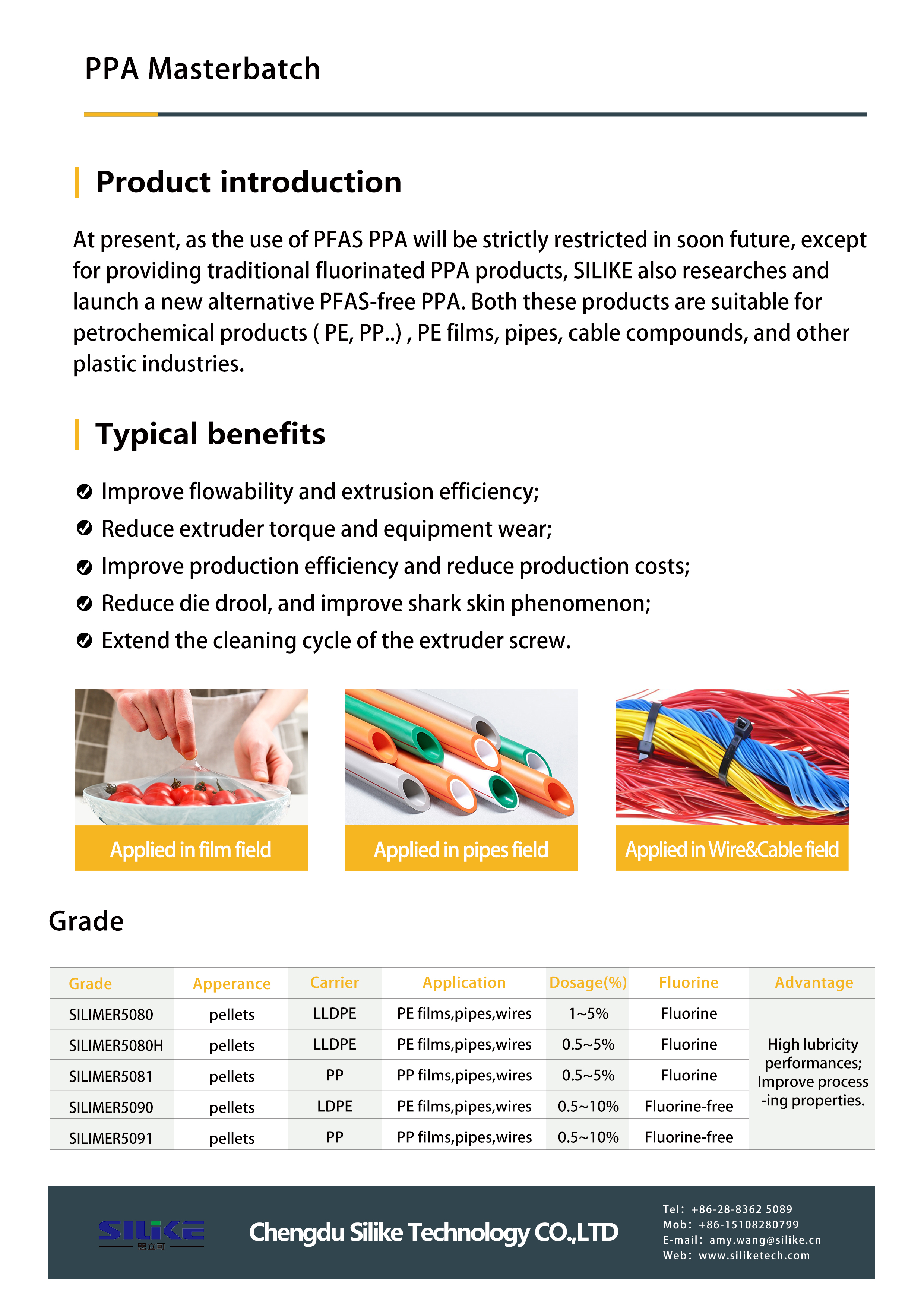

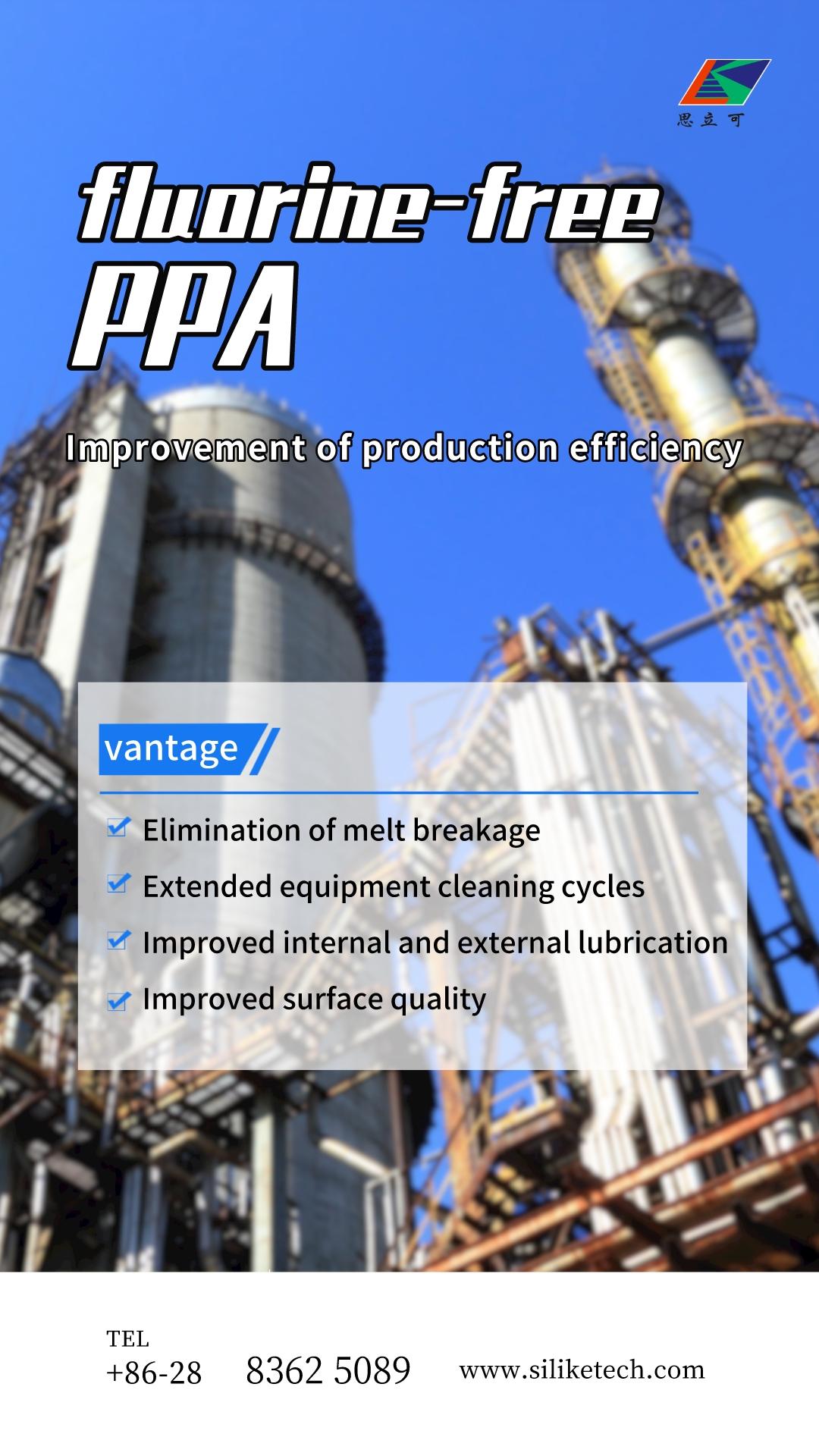

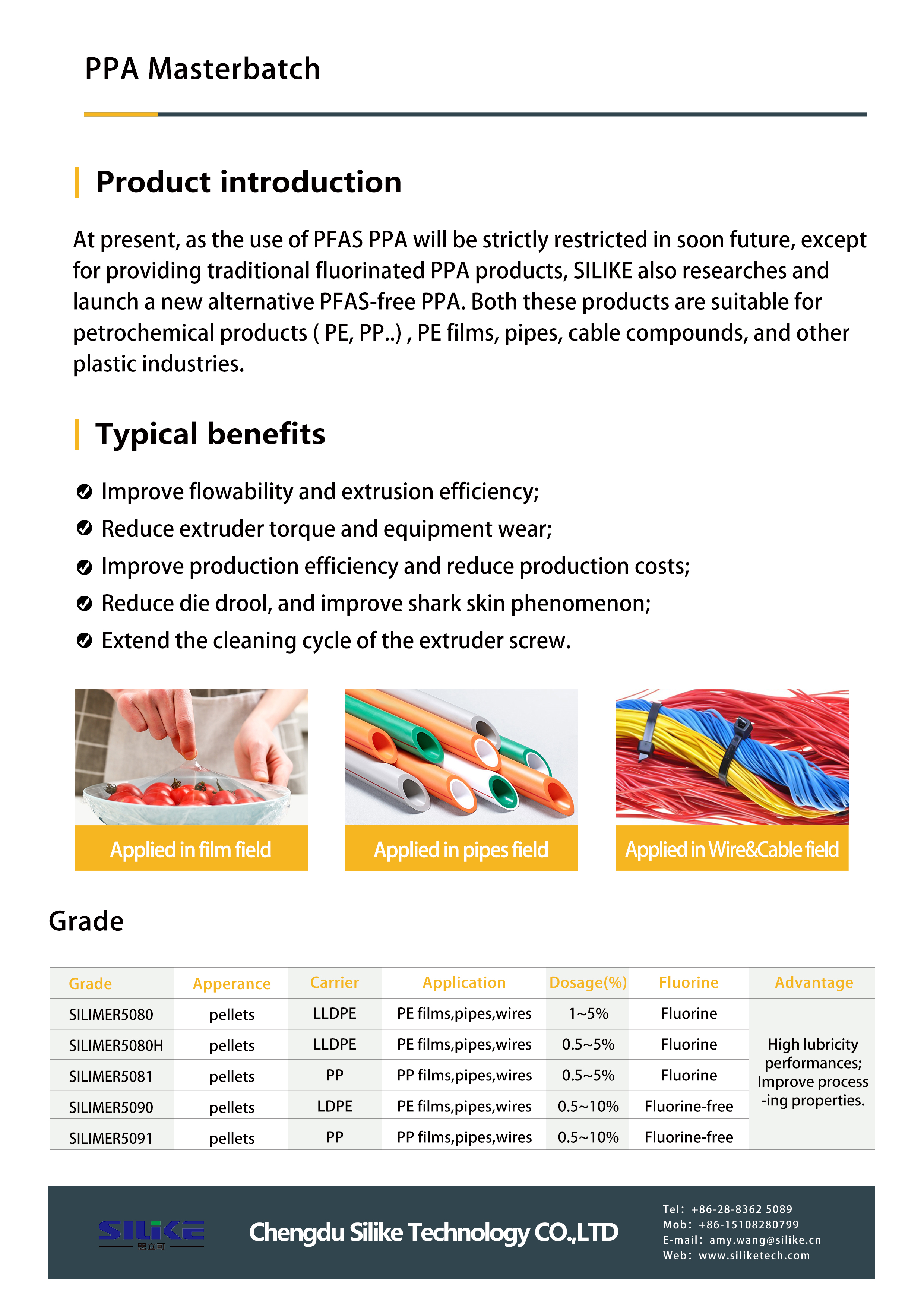

What are PPA processing aids for plastics processing? How to Find Highly Functional PFAS-free PPA processing aids under the Fluorine Ban?

PPA stands for Polymer Processing Aid. Another type of PPA that we often see is Polyphthalamide (polyphthalamide), which is a high-temperature resistant nylon. The two types of PPA have the same acronym, but have completely different uses and functions. PPA polymer processing aids is a general te...Read more -

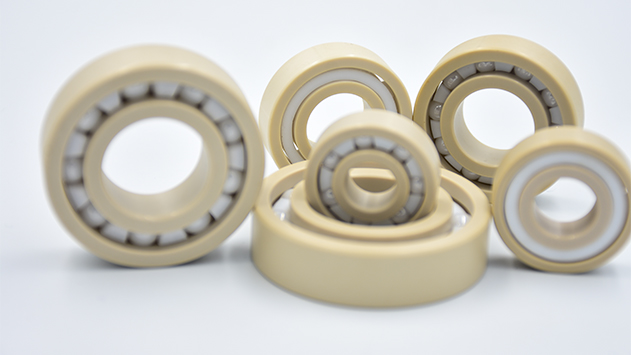

PEEK products have black spot what is the reason, silicone powder how to improve PEEK products black spot problem

PEEK (polyether ether ketone) is a high-performance engineering plastic with a number of excellent physical and chemical properties that make it popular for a variety of high-end applications. Properties of PEEK: 1. high temperature resistance: the melting point of PEEK is up to 343 ℃, can be use...Read more -

What are the effects of poor dispersing performance of black masterbatches, and how to improve the dispersing performance of black masterbatches

What is black masterbatch? Black masterbatch is a kind of plastic colouring agent, which is mainly made of pigments or additives mixed with thermoplastic resin, melted, extruded and pelletised. It is compatible with the base resin in the production process of plastic products and gives them black...Read more -

What material is PET, how to improve the mould release performance of PET products and product quality?

PET (Polyethylene terephthalate) is a thermoplastic polyester with a variety of excellent physical, chemical and mechanical properties, so it has a wide range of applications in industry and daily life. The main characteristics of PET include: 1.High transparency and gloss, making it an ideal cho...Read more -

The Impact of Poor Transparency in Cast Film on Laminating Processes, and how to choose a slip agent that does not affect film transparency

The cast film industry has been witnessing significant growth, driven by the demand for high-quality packaging materials in various sectors. One of the critical properties of cast film is transparency, which not only affects the aesthetic appeal but also the functionality of the final product. Th...Read more -

EVA on shoe outsoles, and effective solutions to improve the abrasion resistance of EVA shoe soles

What is EVA Material? EVA is a lightweight, flexible, and durable material made by copolymerizing ethylene and vinyl acetate. The ratio of vinyl acetate to ethylene in the polymer chain can be adjusted to achieve different levels of flexibility and durability. Applications of EVA in Shoe Sole Ind...Read more -

What are the biodegradable materials, and how to improve the processing performance of PLA, PCL, PBAT and other biodegradable materials

Degradable materials are a class of polymer materials that can be decomposed into harmless substances through microbial action in the natural environment, which is of great significance in alleviating plastic pollution and protecting the environment. Below are details of several common biodegrada...Read more -

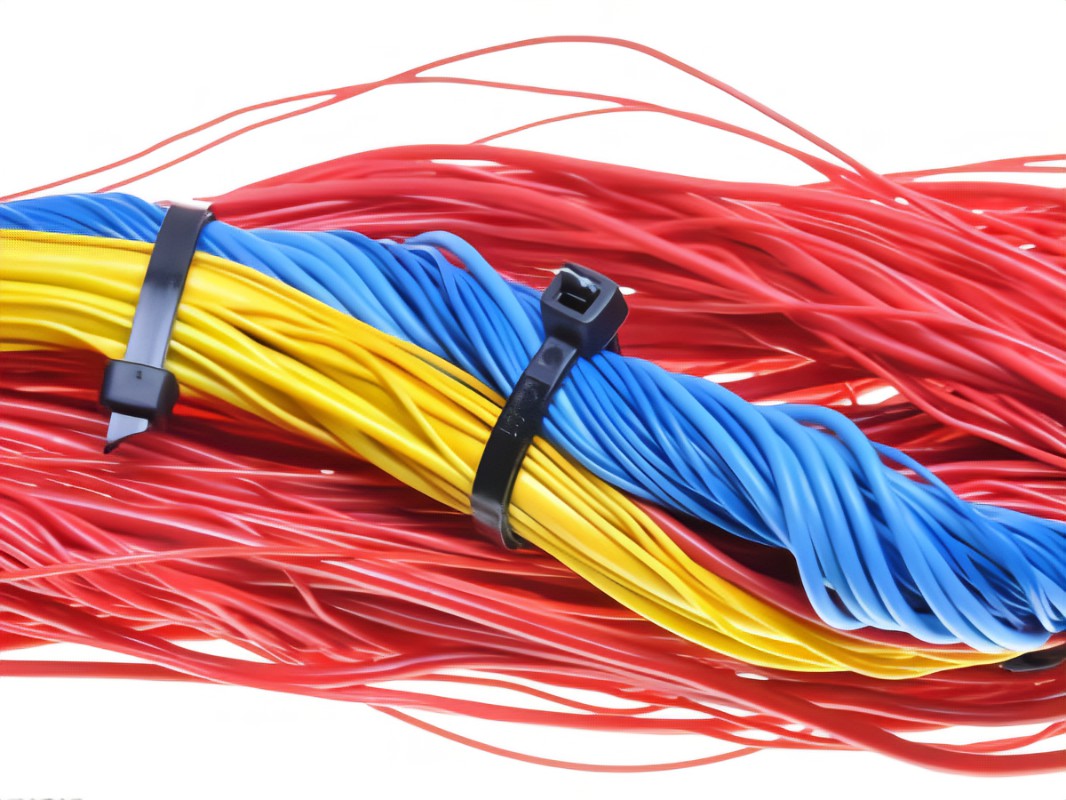

Silicone masterbatch: Solutions to improve the efficiency of extruding different types of wire and cable materials

The cable and wire industry is a cornerstone of modern infrastructure, powering communication, transportation, and energy distribution. With the ever-growing demand for high-performance cables, the industry is constantly seeking innovative solutions to enhance production efficiency and product qu...Read more -

What is the cause of die build-up during masterbatch extrusion? How to solve the problem of masterbatch processing defects?

Colour masterbatches play a vital role in the plastic products manufacturing industry, which can not only provide uniform and vivid colours, but also ensure the stability of the products in the production process. However, there are still a lot of difficulties to be solved in the production of co...Read more -

Silicone Powder: processing solutions for soft PVC to improve wear resistance

As the world’s second largest general-purpose synthetic resin material, PVC has become one of the most widely used plastics due to its excellent flame retardancy, abrasion resistance, chemical corrosion resistance, comprehensive mechanical properties, product transparency, electrical insula...Read more -

Anti-scratch Silicone Masterbatch, efficient solutions to improve wear resistance of TPE automotive foot mats

In recent years, with the rapid growth of the automotive industry, TPE materials have gradually formed an automobile-centred application market.TPE materials are used in a large number of automotive body, interior and exterior trim, structural components and special applications. Among them, in t...Read more -

What Causes Poor Color Dispersion of Color Masterbatch and How to Solve The Problem Of Uneven Dispersion Of color concentrates and compounds?

Color masterbatch is the most common method for coloring plastics, widely used in the plastics processing industry. One of the most critical performance indicators for masterbatch is its dispersion. Dispersion refers to the uniform distribution of the colorant within the plastic material. Whether...Read more -

Solutions for engineering plastics to improve release properties

Engineering plastics (also known as performance materials) are a class of high-performance polymer materials that can be used as structural materials to withstand mechanical stress over a wide range of temperatures and in more demanding chemical and physical environments. It is a class of high-pe...Read more -

High-performance lubricants improve PVC extrusion efficiency, extended equipment cleaning cycles

PVC is one of the world’s largest production of general-purpose plastics with a wide range of applications. It is widely used in building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, foaming mate...Read more -

Sustainable Alternatives, Enhancing Melt Processing of Metallocene Polyethylene Agricultural Films with PFAS-Free PPA

Agricultural film, as a key element in agricultural production, has been evolving and innovating, becoming an important support for ensuring quality crop growth and improving agricultural yield and quality. Agricultural films are mainly divided into the following types: Shed film: used to cover g...Read more -

Effective solution for PA6 floating fibres, significantly improving surface quality and processability.

PA6, also known as nylon 6, is a semi-transparent or opaque milky white particle with thermoplasticity, light weight, good toughness, chemical resistance and durability, etc. It is generally used in automotive parts, mechanical parts, electronic and electrical products, engineering parts and othe...Read more -

What is metallocene polyethylene that improves film properties? How to solve the problem of melt fracture

Metallocene polyethylene(mPE) is a kind of polyethylene resin synthesised on the basis of metallocene catalysts, which is a very important technological innovation in the polyolefin industry in recent years. Product types mainly include metallocene low density high pressure polyethylene, metalloc...Read more -

SILIKE anti-squeak masterbatch, Provides permanent noise reduction for PC/ABS

PC/ABS materials are more commonly used for lifting brackets for display devices and are also commonly used for automotive interiors. Many components used in automotive instrument panels, center consoles, and trim are made from polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) blends. These ...Read more -

Celebrating the 20th Anniversary of Chengdu Silike Technology Co., Ltd, Xi’an and Yan’an Team Building Tour

Established in 2004, Chengdu Silike Technology Co.,LTD. We are a leading provider of modified plastic additives, offering innovative solutions to enhance the performance and functionality of plastic materials. With years of experience and expertise in the industry, we specialize in developing and...Read more -

Silicone Masterbatches: Enhancing Plastics with Versatility and Durability

About SILIKE Silicone Masterbatch: SILIKE Silicone masterbatch is a kind of functional masterbatch with all kinds of thermoplastics as the carrier and organo-polysiloxane as the active ingredient. On the one hand, silicone masterbatch can improve the fluidity of thermoplastic resin in the molten ...Read more -

A Solution for Controlled Coefficient of Friction in Cast Polypropylene Films

Daily necessities like food and household items are indispensable in people’s daily lives. As the pace of life continues to accelerate, various packaged foods and daily necessities have filled supermarkets and shopping malls, making it convenient for people to purchase, store, and use these...Read more -

How to solve the influence of migration type slip agent on the heat sealing performance of heavy-duty packaging film

Heavy-duty form-fill-seal (FFS) Packaging PE film from the beginning of the single-layer blending process to the three-layer co-extrusion process, with the continuous popularity of three-layer co-extrusion technology, the market has fully recognized the technical advanta...Read more -

How to improve the extrusion rate of wire and cable, and solve the die drool

The raw materials mainly used in the traditional cable industry include copper and aluminum as conductor materials, and rubber, polyethylene, polyvinyl chloride as insulation and sheathing materials. These traditional insulating sheathing materials will produce a large number of toxic fumes and c...Read more -

How to improve the surface smoothness of PBT injection molding products

Polybutylene terephthalate (PBT), a polyester made by polycondensation of terephthalic acid and 1,4-butanediol, is an important thermoplastic polyester and one of the five major engineering plastics. Properties of PBT Mechanical properties: High strength, fatigue resistance, dimensional stabilit...Read more -

PFAS-Free PPA: Solving Issues of Melt Fracture in Heavy-Duty Form-Fill-Seal (FFS) Packaging Processing

Heavy-duty form-fill-seal (FFS) Packaging, or FFS packaging for short, is a plastic film used for heavy-duty packaging, which usually has high mechanical strength, puncture resistance, and good sealing performance. This kind of packaging film is widely used in industrial products, construction ma...Read more -

Enhance the wear resistance of polypropylene(CO-PP/HO-PP) and extend the service life of the product.

Polypropylene (PP), one of the five most versatile plastics, is used in a wide range of applications in everyday life, including food packaging, medical equipment, furniture, automotive parts, textiles and more. Polypropylene is the lightest plastic raw material, its appearance is colourless tran...Read more -

PFAS-free PPA solves the difficulties of functional masterbatch processing: eliminate melt fracture, reduce die build-up.

Plastic functional masterbatch is an innovative material widely used in the production of plastic products. It has a variety of functions, including improving the strength of objects, increasing wear resistance, enhancing appearance, and protecting the environment. In this paper, we will discuss ...Read more -

Revolutionizing Cable Manufacturing: The Role of Silicone Powders and Masterbatches in Wire and Cable Materials

Introduction: The electrical industry has always been at the forefront of technological advancements, with constant innovations in materials and manufacturing processes. Among these innovations, silicone powders and masterbatches have emerged as game-changers in the wire and cable industry. This ...Read more -

Anti-abrasion masterbatch NM series, Wear-resistant solutions for shoe outsoles

Common materials for shoe outsoles include a wide range of types, each with its own unique advantages and disadvantages, as well as specific areas of application. Below are some common shoe outsole materials and their properties: TPU (thermoplastic polyurethane) - Advantages: good abrasion, fo...Read more -

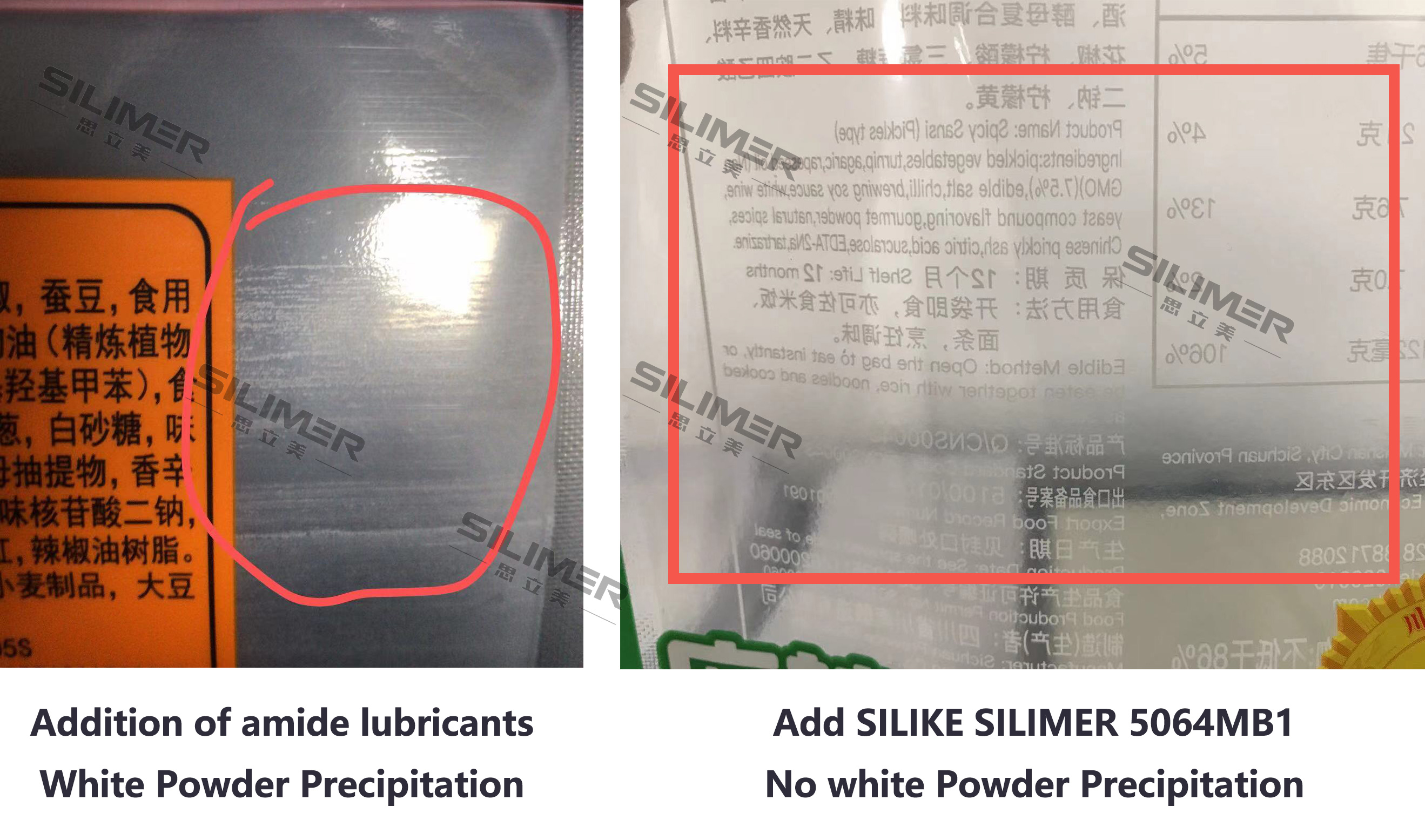

How to Minimize Additive Blooming and Migration in Flexible Packaging

In the intricate world of flexible packaging, where aesthetics, functionality, and performance converge, the phenomenon of additive blooming can present a significant challenge. Additive blooming, characterized by the migration of additives to the surface of packaging materials, can mar the appea...Read more -

Revolutionising Scratch Resistance in Automotive Interiors with Anti-Scratch Additives and Silicone Masterbatches

Introduction to Anti-Scratch Additives In the automotive industry, the quest for innovation is relentless. One such advancement is the incorporation of anti-scratch additives into the manufacturing process. These additives are designed to enhance the durability and aesthetics of car interiors by ...Read more -

The Rise of PFSA-free PPA Masterbatches: A Sustainable Alternative in the Petrochemical Industry

Metallocene Polyethylene (mPE) Properties: mPE is a type of polyethylene that is produced using metallocene catalysts. It is known for its superior properties compared to conventional polyethylene, including: - Improved strength and toughness - Enhanced clarity and transparency - Better processab...Read more -

Silicone Powder: Revolutionizing PPS Plastic Applications

Introduction Silicone powder, also known as silica powder, has been making waves in the world of plastics engineering. Its unique properties and versatility have led to its widespread application in various plastic materials, including PPS (polyphenylene sulfide). In this blog, we will delve into...Read more -

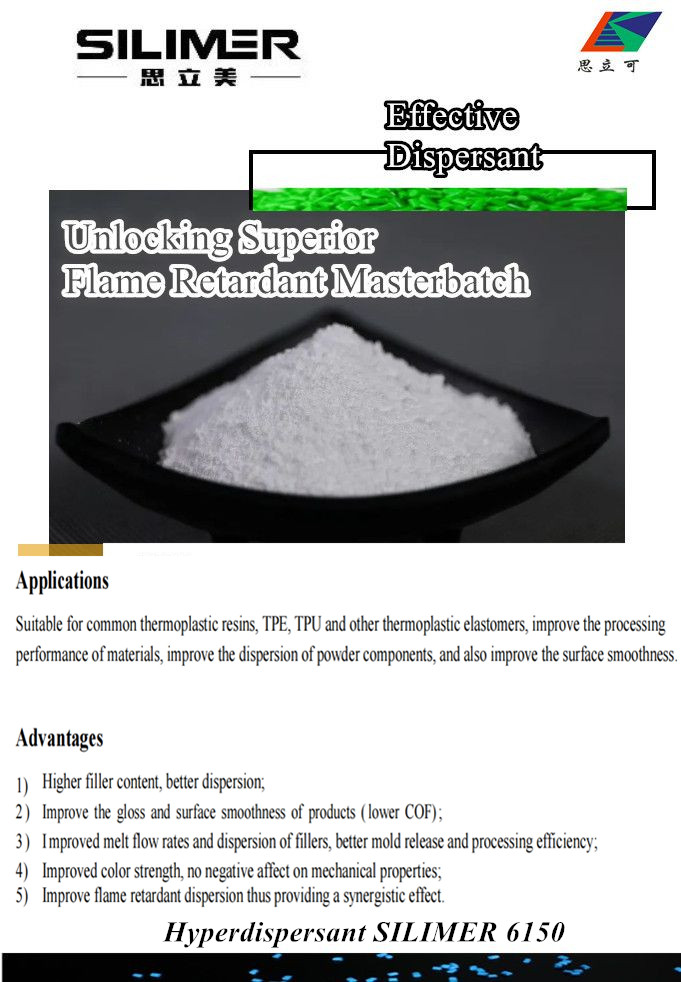

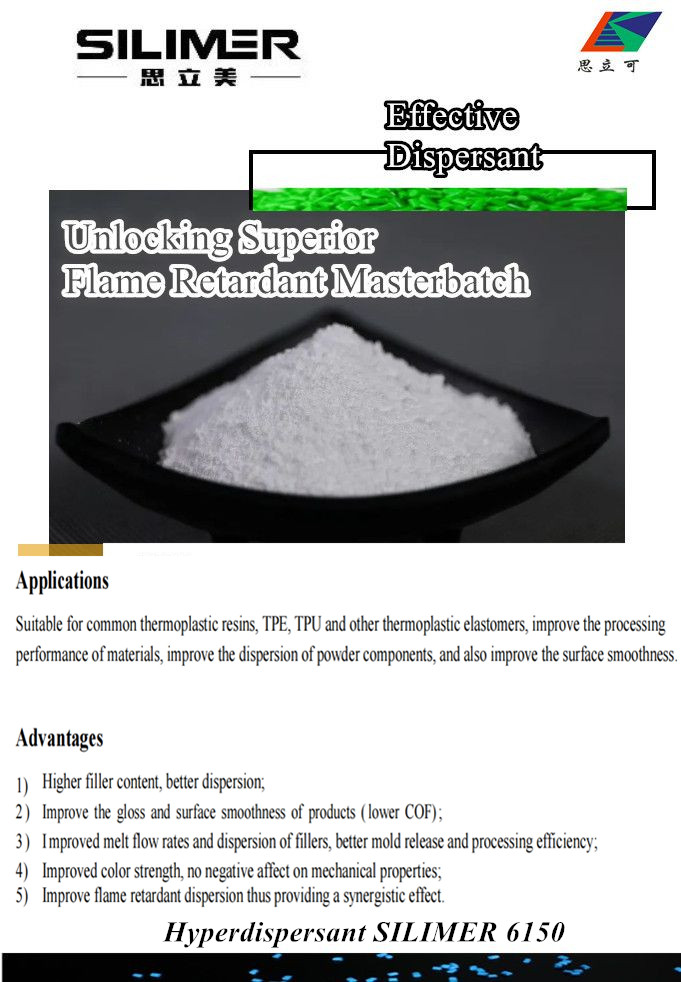

Effective solutions for uneven dispersion of flame retardant masterbatch

Flame retardant masterbatch, is one of the best flame retardant products in plastics and rubber resins. Flame retardant masterbatch is a kind of granular product made by mixing, extruding and pelletizing through twin-screw or three-screw extruders on the basis of flame retardant and organic combi...Read more -

Environmentally friendly new material, providing more skin-friendly and easy-to-clean collars for pets

Nowadays, pets have become a member of many families, and pet owners pay more attention to the safety and comfort of their pets. A good pet collar should first of all be resistant to cleaning, if it is not resistant to cleaning, then the collar will continue to breed mold, in the long run, the st...Read more -

LDPE blow molding film common faults and solutions

LDPE films are generally made by both blow molding and casting processes. Cast polyethylene film has a uniform thickness, but is rarely used due to its high price. Blown polyethylene film is made from blow-molded grade PE pellets by blow-molding machines, which is the most widely used because of ...Read more -

Effective solution to reduce the coefficient of friction of the inner wall of HDPE Telecom pipe

HDPE Telecom pipe, or PLB HDPE Telecom Ducts, Telecommunication ducts, Optical fiber duct / Microduct, outdoor telecommunication optical fiber, optical fiber cable, and Large diameter pipe, etc…, is a new type of composite pipe with a silicone gel solid lubricant on the inner wall. The mai...Read more -

High-gloss PC/ABS plastic solution to improve scratch resistance

PC/ABS is an engineering plastic alloy made by blending polycarbonate (PC for short) and acrylonitrile butadiene styrene (ABS for short). This material is a thermoplastic plastic that combines the excellent mechanical properties, heat and impact resistance of PC with the good processability of AB...Read more -

Effective solutions for improving processability and productivity of LSZH and HFFR cable materials

Low-smoke halogen-free cable material is a special cable material that produces less smoke when burned and does not contain halogens (F, Cl, Br, I, At), so it does not produce toxic gases. This cable material is mainly used in places with high requirements for fire safety and environmental protec...Read more -

PFAS-free PPA is used in flexible packaging materials to improve product competitiveness from raw materials

Flexible packaging is a form of packaging made from flexible materials that combines the advantages of plastic, film, paper and aluminium foil, with features such as lightweight and portability, good resistance to external forces, and sustainability. Some of the materials used in flexible packagi...Read more -

Silicone Masterbatch: Improve the mold release and processing performance of HIPS, and improve the surface quality

High Impact Polystyrene, often referred to as HIPS, is a thermoplastic material made from elastomer-modified polystyrene. The two-phase system, consisting of a rubber phase and a continuous polystyrene phase, has evolved into an important polymer commodity worldwide, and...Read more -

Sustainable Products at Chinaplas 2024

From April 23 to 26, Chengdu Silike Technology Co., Ltd attended Chinaplas 2024. In this year’s exhibition, SILIKE has closely followed the theme of low carbon and green era, and empowered silicone to bring PFAS-free PPA, new silicone hyperdispersant, non-precipitated film opening and slid...Read more -

Si-TPV Modified soft slip TPU granules, Ideal eco-friendly material for children’s toy products

Children’s toys according to the main material points, mainly by the wooden, plastic, rubber, metal, mud and sand, paper, plush fabric. Wooden, plastic and plush are the three main categories. Let us first do a plastic toy material and understand it. Plastic toys material are: polystyrene (...Read more -

PFAS-free PPA: Making PE pipe processing more efficient and environmentally friendly

PE pipe, or polyethylene pipe, is a type of pipe that is molded by extrusion using polyethylene as the main raw material. It can be defined in terms of its material properties and application areas. Polyethylene is a thermoplastic with good chemical and environmental stress cracking resistance, w...Read more -

Understanding Blown Film: Overcoming Plastic Film Odor with Effective Methods

What is Blown Film and application? Blown film is a plastics processing method, that refers to the plastic particles heated and melted and then blown into a film of a plastics processing technology, usually using the polymer extrusion molding tubular film billet, in a better state of melt flow th...Read more -

Innovative Solutions for Shoe Durability and Comfort: Anti-Abrasion Technology

Globally, the annual market consumption of EVA is increasing, and it is widely used in the fields of foamed shoe materials, functional shed films, packaging films, hot melt adhesives, EVA shoe materials, wires and cables, and toys. The specific application of EVA is decided according to its VA co...Read more -

What are SILIKE PFAS-Free Polymer Processing Aids (PPA)?

Introduction: Polymer processing aids (PPAs) are indispensable in optimizing the performance of polyolefin films and extrusion processes, particularly in blown film applications. They serve crucial functions such as eliminating melt fractures, improving film quality, enhancing machine throughput,...Read more -

Overcoming Common Challenges and Solutions with Color Masterbatch in Injection Molding

Introduction: Color masterbatch is the lifeblood of visual appeal and aesthetic finesse in plastic products crafted through injection molding. However, the journey towards consistent color, top-tier quality, and impeccable surface finish is often riddled with challenges stemming from pigment disp...Read more -

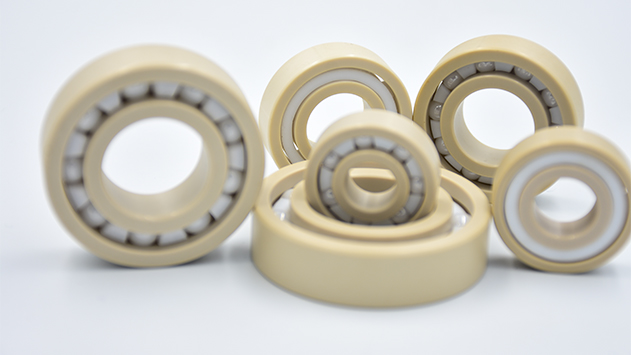

The application of POM materials in engineering plastics and its advantages, disadvantages and Solutions.

POM, or polyoxymethylene, is an important engineering plastic with excellent physical and chemical properties and is widely used in many fields. This paper will focus on the characteristics, application areas, advantages, and disadvantages as well as processing difficulties of POM materials, and ...Read more -

What is PFAS-free Polymer Processing Aids?

Understanding PFAS-free Polymer Processing Aids In recent years, there has been a growing concern over the use of per- and polyfluoroalkyl substances (PFAS) in various industries, including polymer processing. PFAS are a group of man-made chemicals that have been widely used in numerous consumer ...Read more -

How to Solve Wood Powder Dispersion Challenges in Wood Plastic Composite Granulation?

Wood Plastic Composite(WPC) products are made of plastic (PP, HDPE, PVC, PS, ABS) and plant fiber (sawdust, waste wood, tree branches, crop straw powder, husk powder, wheat straw powder, peanut shell powder, etc.) as the main raw materials, together with other additives, through the extrusion of ...Read more -

Interpretation of automotive interiors: how to improve the scratch resistance of automotive dashboard surfaces

Automotive interior refers to interior components and automotive products used for interior modification of automobiles that have certain decorative and functional, safety, and engineering attributes. The automotive interior system is an important part of the car body, and the design workload of ...Read more -

How to improve the surface wear resistance of PA6 materials

Polyamide resin, abbreviated as PA, is commonly known as nylon. It is a macromolecular main chain repeating units containing amide groups in the polymer of the general term. The five engineering plastics in the largest production, the most varieties, the most widely used varieties, and other poly...Read more -

PFAS-free PPA in polyethylene films

Polyethylene(PE) film, is a film produced from PE pellets.PE film is moisture resistant and has low moisture permeability. Polyethylene film (PE) can be manufactured with different properties such as low density, medium density, high-density polyethylene, and cross-linked polyethylene depending o...Read more -

How to improve the surface abrasion resistance of PVC cable material

PVC cable material is composed of polyvinyl chloride resin, stabilizers, plasticizers, fillers, lubricants, antioxidants, coloring agents, and so on. PVC cable material is inexpensive and has excellent performance, in wire and cable insulation and protection materials have long occupied an import...Read more -

How to improve the production defects of CPP film? Solutions for Surface Crystal Spots

CPP film is a film material made from polypropylene resin as the main raw material, which is bi-directionally stretched through extrusion molding. This bi-directional stretching treatment makes CPP films have excellent physical properties and processing performance. CPP films are widely used in t...Read more -

Everything You Need to Know About PFAS & PFAS-Free PPA.

To ensure that the products we manufacture are compliant and safe, SILIKE’s research and development team pays close attention to the ever-changing regulatory environment and laws and regulations, always keeping sustainable and environmentally friendly operations. Per- and poly-fluoroalkyl ...Read more -

New energy era, how to improve the surface quality of TPU cable material.

With the global emphasis on environmental protection and sustainable development, the new energy vehicle market is booming. Electric vehicles(EV) as one of the main choices to replace traditional fuel vehicles, with the development of new energy vehicles(NEVS), many cable companies have transform...Read more -

Enhance the abrasion resistance of TPU soles and increase the service life of the products.

TPU (thermoplastic polyurethane elastomer), due to excellent physical and mechanical properties, such as high strength, high toughness, high elasticity, high modulus, but also chemical resistance, abrasion resistance, oil resistance, vibration damping ability, such as excellent comprehensive perf...Read more -

Causes and Solutions of Crystallization Points in PE Film.

Plastic film is a kind of plastic product widely used in packaging, agriculture, construction, and other fields. It is lightweight, flexible, transparent, water-resistant, acid- and alkali-resistant, and has good moisture-proof, dust-proof, freshness preservation, heat insulation, and other funct...Read more -

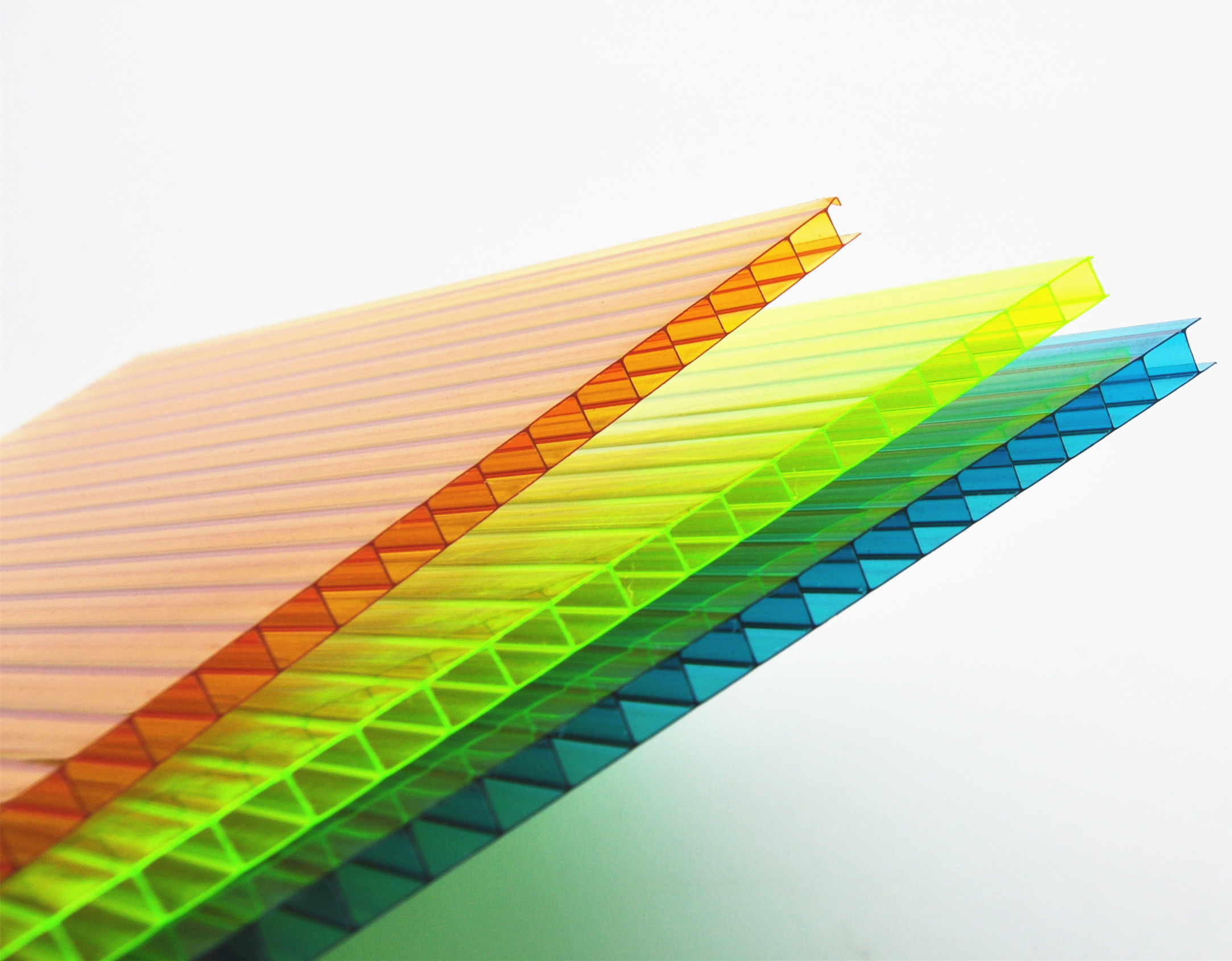

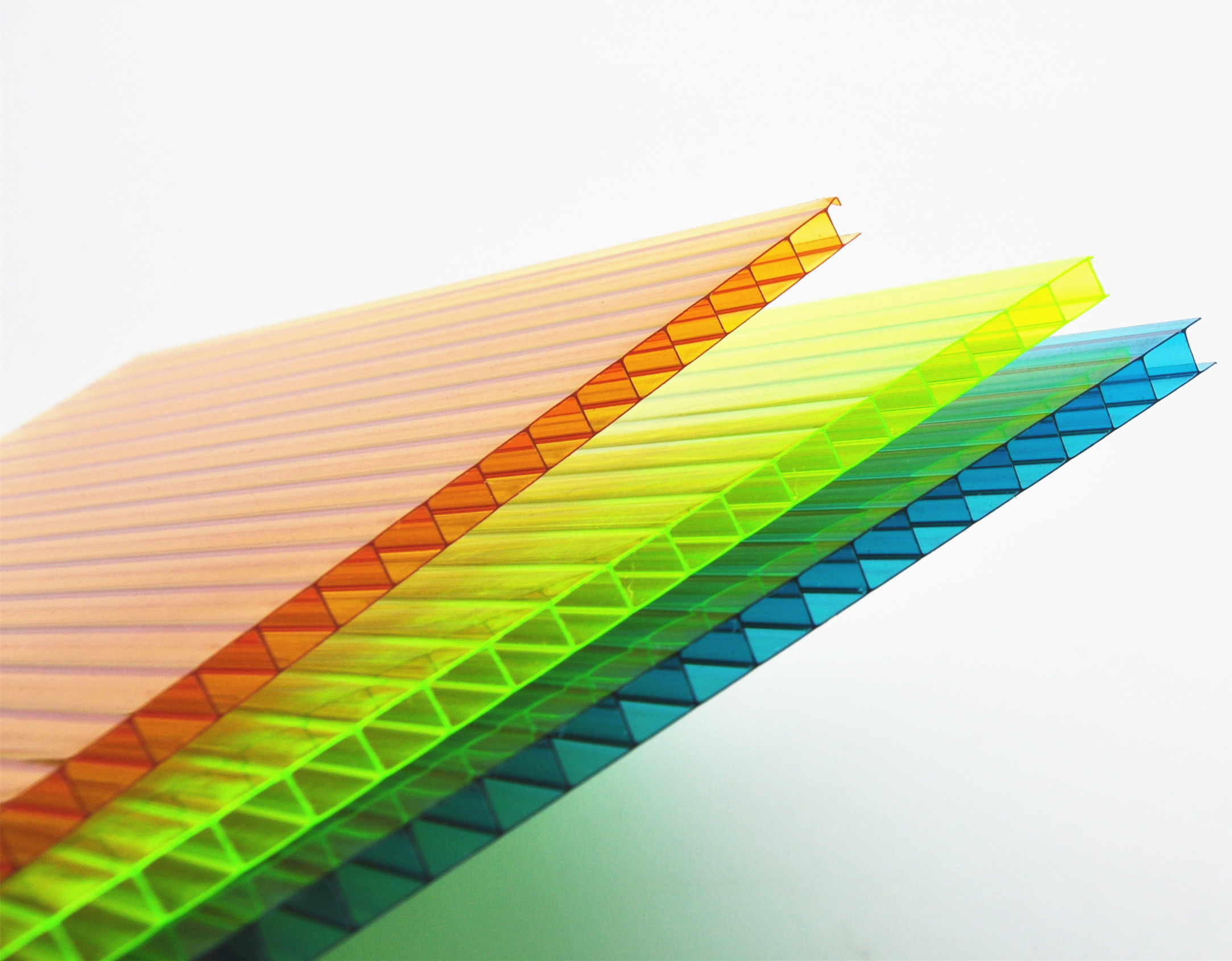

How to solve the issue of scratches appearing on the surface of PC boards?

The sunshine board is mainly prepared from PP, PET, PMMA PC, and other transparent plastics, but now the main material of the sunshine board is PC. So usually, sunshine board is the common name for polycarbonate (PC) board. 1. Application areas of PC sunlight board The application range of PC sun...Read more -

Optimizing PP-R Pipe Processing: SILIKE’s PFAS-Free PPA for Enhanced Performance and Environmental Compliance

What is PP-R Pipe? PP-R (polypropylene random) pipe, also known as tripropylene polypropylene pipe, random copolymer polypropylene pipe, or PPR pipe, is a kind of pipe using random copolymer polypropylene as raw material. It is a high-performance plastic pipe with excellent thermoplasticity and c...Read more -

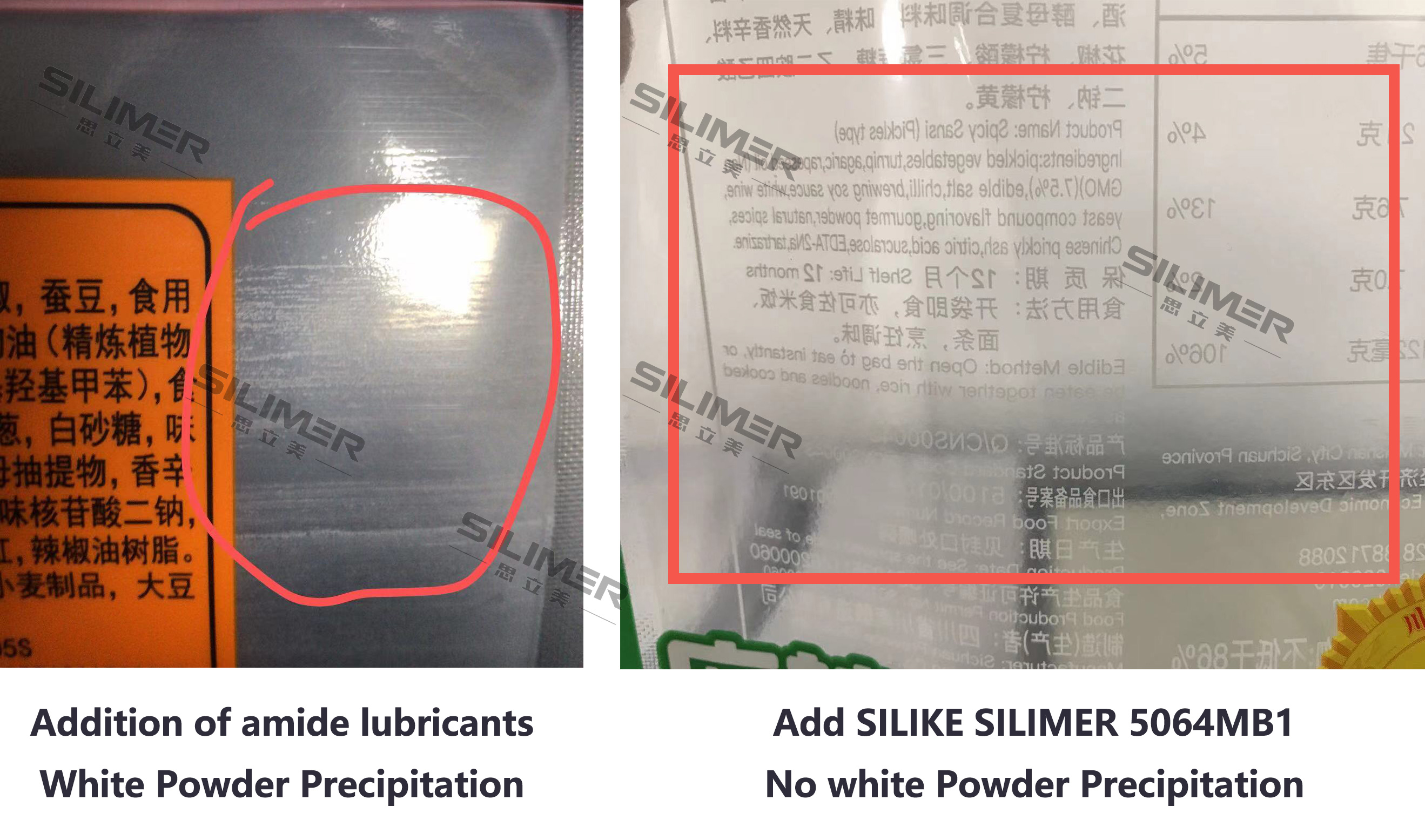

SILIMER series non-precipitation slip and anti-blocking agent masterbatch ——solving the problem of precipitation out of powder in the film

The white powder precipitating on the food packaging bag is because the slip agent (oleic acid amide, erucic acid amide) used by the film manufacturer itself precipitates, and the mechanism of the traditional amide slip agent is that the active ingredient migrates to the surface of the film, form...Read more -

PFAS-free PPA Polymer Processing Aids – Why Use Them and What’s the Concern with PFAS?

1.Application of PPA processing aids containing PFAS polymers PFAS (perfluorinated compounds) are a class of chemical substances with perfluorocarbon chains, which have some unique properties in practical production and application, such as very high surface energy, low coefficient of friction, s...Read more -

Advantages and disadvantages of common Slip Additives for Plastic Film and how to select them

Plastic Film is made of PE, PP, PVC, PS, PET, PA, and other resins, used for flexible packaging or laminating layer, are widely used in food, medicine, chemicals, and other fields, of which food packaging accounted for the largest proportion. Among them, PE film is the most widely used, the large...Read more -

How does fluoride-free PPA improve the processability of color masterbatch

Color Masterbatch, also known as a color seed, is a new type of special coloring agent for polymer materials, also known as Pigment Preparation. It consists of three basic elements: pigment or dye, carrier, and additives. It is an aggregate obtained by uniformly attaching an extraordinary amount ...Read more -

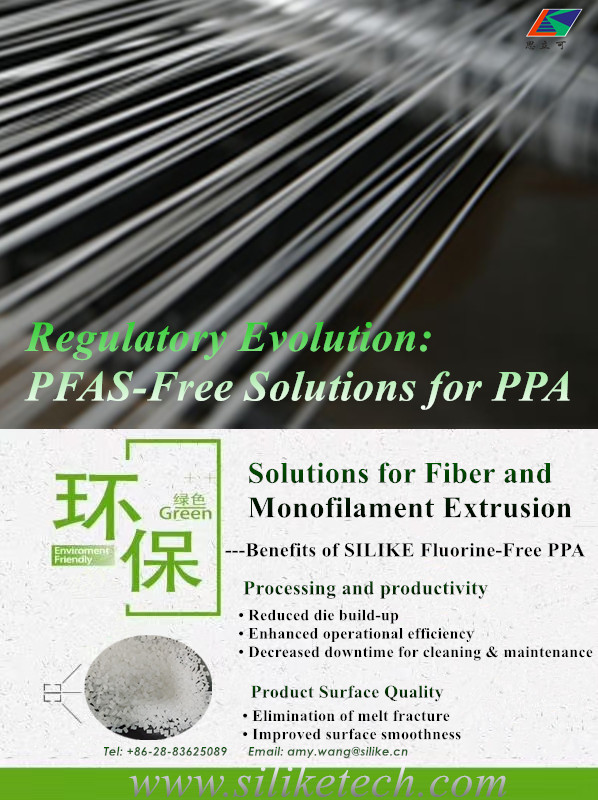

Innovation and Compliance with Upcoming Regulations: PFAS-Free Solutions for the Green Industry

Understanding Fiber and Monofilament: Fiber and Monofilament are single, continuous strands or filaments of a material, typically a synthetic polymer like nylon, polyester, or polypropylene. These filaments are characterized by their single-component structure, as opposed to multifilament yarns...Read more -

Effective methods to improve the wear resistance of PP plastic surface

Polypropylene (PP) is a polymer made from propylene through polymerization. Polypropylene is a thermoplastic synthetic resin with excellent performance, it is a colorless and semi-transparent thermoplastic light-weight general-purpose plastic with chemical resistance, heat resistance, electrical ...Read more -

How fluorine-free PPA improves productivity in spinning processes?

Spinning, also known as chemical fiber forming, is the manufacturing of chemical fibers. Is made of certain polymer compounds into a colloidal solution or melted into a melt by the spinneret pressed out of the fine holes to form the process of chemical fibers. There are two main types of processi...Read more -

How to Solve the Issue of Uneven Dispersion of Wood Powder During PE-based WPC Molding?

Polyethylenepe-based wood plastic composites (PE-based WPC) is a new type of composite material at home and abroad in recent years, refers to the use of polyethylene and wood flour, rice husk, bamboo powder, and other plant fibers mixed into a new wood material, mixing and granulation of composit...Read more -

How to solve the wear and tear of POM during high-speed extrusion?

Polyformaldehyde (simply as POM), also known as polyoxymethylene, is a thermoplastic crystalline polymer, known as “super steel”, or “race steel”. From the name can be seen POM has a similar metal hardness, strength, and steel, in a wide range of temperatures and humidity ...Read more -

How to Solve White Powder Precipitation in Composite Packaging Film for Food Packaging Bags?

Composite Packaging Film is two or more materials, after one or more dry laminating processes and combined, to constitute a certain function of the packaging. Generally can be divided into the base layer, functional layer, and heat sealing layer. The base layer mainly plays the role of aesthetics...Read more -

How to improve the processing performance of PVC material

PVC (Polyvinyl Chloride) is a commonly used synthetic material obtained by reacting ethylene and chlorine at high temperatures and has excellent weather resistance, mechanical properties, and chemical stability.PVC material mainly comprises polyvinyl chloride resin, plasticizer, stabilizer, fille...Read more -

How does fluorine-free PPA improve plastic pipe processing performance?

Plastic pipe is a common piping material that has been widely used in many fields due to its plasticity, low cost, lightweight, and corrosion resistance. The following are several common plastic pipe materials and their application areas and roles: PVC pipe: polyvinyl chloride (PVC) pipe is one o...Read more -

How to improve the processability of high-gloss (optical) plastics without compromising finish and texture

High-gloss (optical) plastics usually refer to plastic materials with excellent optical properties, and common materials include polymethylmethacrylate (PMMA), polycarbonate (PC), and polystyrene (PS). These materials can have excellent transparency, scratch resistance, and optical uniformity aft...Read more -

How to reduce the product defective rate of PET fiber?

Fibers are elongated substances of a certain length and fineness, usually consisting of many molecules. Fibers can be divided into two categories: natural fibers and chemical fibers. Natural Fibres: Natural fibers are fibers extracted from plants, animals, or minerals, and common natural fibers i...Read more -

How to solve the uneven dispersion of color masterbatch granulation?

Color masterbatch is a granular product made by mixing and melting pigments or dyes with a carrier resin. It has a high concentration of pigment or dye content and can be easily added to plastics, rubber, and other materials for adjusting and obtaining the desired color and effect. The range of a...Read more -

Innovative Solutions: Enhancing Efficiency in Metallocene Polypropylene Production!

“Metallocene” refers to the organic metal coordination compounds formed by transition metals (such as zirconium, titanium, hafnium, etc.) and cyclopentadiene. Polypropylene synthesized with metallocene catalysts is called metallocene polypropylene (mPP). Metallocene polypropylene (mPP...Read more -

How to improve the processing performance of plastic injection molded products?

Plastic injection molded products refer to a variety of plastic products obtained by injecting molten plastic materials into molds through the injection molding process, after cooling and curing. Plastic injection molded products have the characteristics of lightweight, high molding complexity, h...Read more -

How to solve the difficulties encountered in the processing of plastic sheets

Plastic sheets are widely used in various fields, but plastic sheets may have some performance defects during production and processing, which may affect the quality and applicability of the product. The following are some common performance defects that may occur in the production and processing...Read more -

Sustainable Solutions in Polymer Processing Additives for Petrochemicals

Petrochemical plants play a crucial role in the production of a wide range of materials that impact various industries, and one of the key products they manufacture is polymers. Polymers are large molecules composed of repeating structural units known as monomers. Step-by-Step Guide to Polymer Ma...Read more -

How to improve the abrasion resistance of TPR soles

TPR sole is a new type of thermoplastic rubber mixed with SBS as the base material, which is environmentally friendly and does not need vulcanization, simple processing, or injection molding after heating.TPR sole has the characteristics of small specific gravity, lightweight shoe material, good ...Read more -

How to improve the performance of flame retardant materials for new energy vehicles

The term new energy vehicles (NEVs) is used to designate automobiles that are fully or predominantly powered by electric energy, which include plug-in electric vehicles(EVs) — battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) — and fuel cell electric vehicles (FCEV). E...Read more -

How to choose a suitable release agent?

In the die-casting process, the mold is constantly heated by high-temperature liquid metal, and its temperature rises continuously. Excessive mold temperature will make the die casting produce some defects, such as sticking mold, blistering, chipping, thermal cracks, etc. At the same time, the mo...Read more -

Fluorine-free PPA in wire and cable applications

Polymer Processing Additives (PPA) is a general term for several types of materials used to improve the processing and handling properties of polymers, mainly in the molten state of the polymer matrix to play a role. Fluoropolymers and silicone resin polymer processing aids are mainly used in pol...Read more -

Effective Solutions for Improving TPU Sole Wear Resistance

As people begin to pursue a healthy lifestyle, people’s enthusiasm for sports has risen. Many people began to love sports and running, and all kinds of sports shoes have become the standard equipment when people exercise. The performance of running shoes is related to design and materials. ...Read more -

How to choose the right additives for wood-plastic composites?

The correct choice of additives is a key factor both in the enhancement of the inherent properties of wood-plastic composites(WPCs) and in the improvement of processing properties. Problems of warping, cracking, and staining sometimes appear on the surface of the material, and this is where addit...Read more -

Effective solutions to improve the processing performance of plastic pipes

With the continuous development of the city, the world under our feet is also gradually changing, now we are almost every moment under the feet of the pipeline is full of pipes, so now the pipeline is very important for people’s quality of life. There are many kinds of pipe materials, and d...Read more -

What are the common types of additives for wires and cables?

Wire and cable plastics (referred to as cable material) are varieties of polyvinyl chloride, polyolefins, fluoroplastics, and other plastics (polystyrene, polyester amine, polyamide, polyimide, polyester, etc.). Among them, polyvinyl chloride, and polyolefin accounted for the vast majority of the...Read more -

Discover Hyperdispersant, Reshaping flame retardant Industries!

In an era where safety standards and regulations are paramount, the development of materials that resist the spread of fire has become a critical aspect of various industries. Among these innovations, flame retardant masterbatch compounds have emerged as a sophisticated solution to enhance the fi...Read more -

How to solve the BOPP film easy-to-deformation rupture problem?

With the rapid development of the plastic packaging industry, polyolefin film packaging materials are increasingly broadening the scope of application, the use of BOPP film for packaging production (such as molding cans sealing), friction will have a negative impact on the appearance of the film,...Read more -

How to improve the scratch resistance of Automotive interiors?

With the improvement of people’s consumption level, automobiles have gradually become a necessity for daily life and traveling. As an important part of the car body, the design workload of automotive interior parts accounts for more than 60% of the workload of automotive styling design, far...Read more