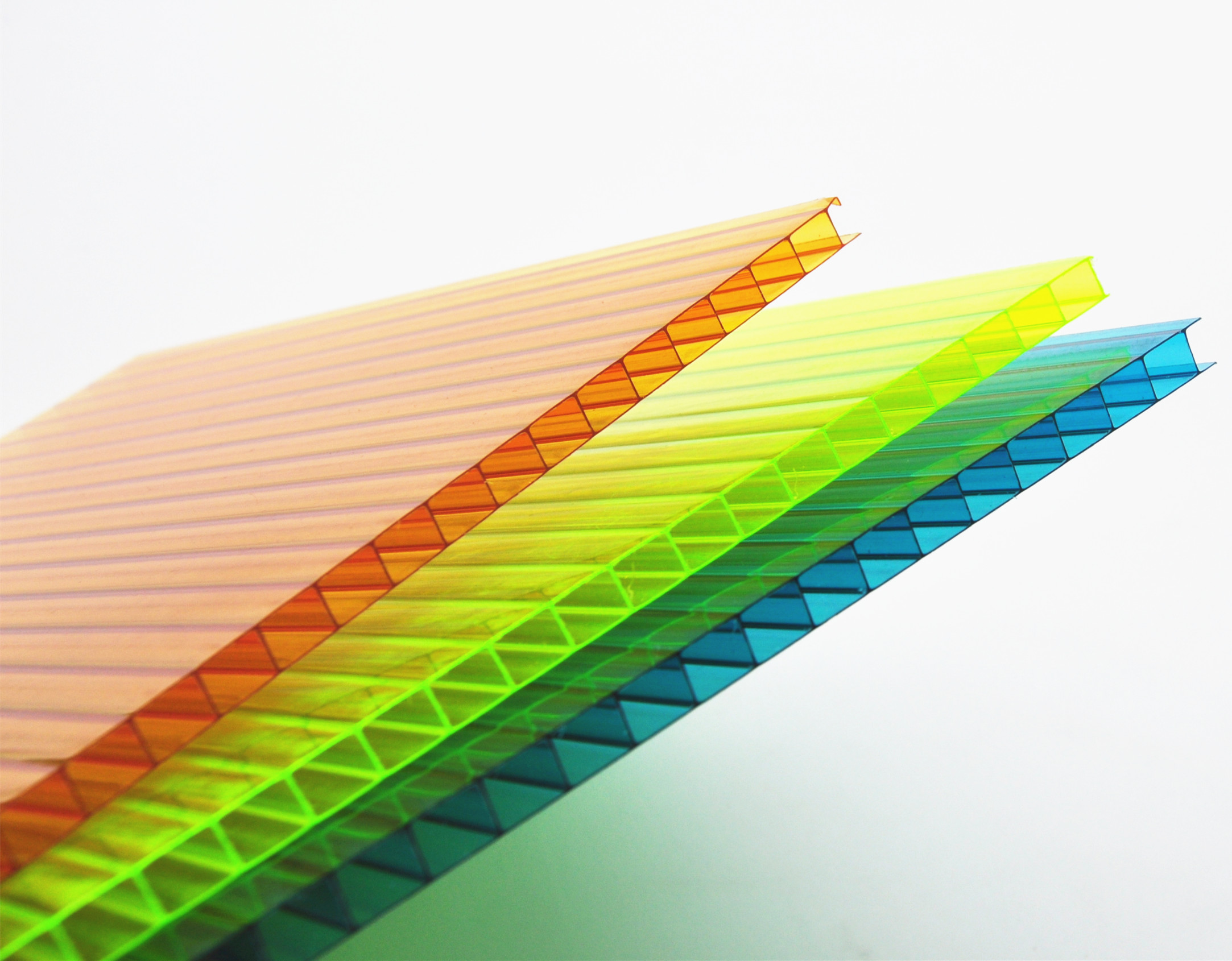

The sunshine board is mainly prepared from PP, PET, PMMA PC, and other transparent plastics, but now the main material of the sunshine board is PC. So usually, sunshine board is the common name for polycarbonate (PC) board.

1. Application areas of PC sunlight board

The application range of PC sunshine boards is very wide, covering almost all industries. The light canopy and sunshade canopy of factories, stadiums, stations, and other utilities seen in daily life, highway soundproofing, advertising and decoration, stadiums, swimming pools, warehouse light roofs, residential and commercial buildings light canopy, exhibition lighting, decoration, agricultural greenhouses, aquaculture, and flower trellises, as well as telephone booths, kiosks, greenhouses/industrial plants, advertisement signboards, parking sheds, access light poncho field, the PC sunshine board, has made a great contribution to people’s life.

2. Characteristics of PC sunlight board

PC sunshine board is mainly processed by high-performance engineering plastics – polycarbonate (PC) resin, the advantages of which are ultra-high transparency, lightweight, impact resistance, sound insulation, heat insulation, flame retardant, longer service life, etc., it is a high-tech, excellent comprehensive performance, energy saving and environmentally-friendly It is a kind of high-tech, excellent comprehensive performance, energy-saving, and environmentally friendly plastic sheet. Characteristics:

Light transmittance: PC board light transmittance up to 89% or more, can be compared with the mother of glass.

UV protection: PC board by UV treatment in the sunburst will not produce yellowing, fogging, and so on.

Flame retardant: PC board’s ignition point is 580 degrees Celsius, self-extinguishing after leaving the fire, the combustion will not produce toxic gases, and will not contribute to the spread of fire.

Sound insulation: The PC board sound insulation effect is obvious, and the same thickness of glass and acrylic board has better sound insulation, which is the panel material of the highway noise barrier.

Energy-saving: Keep cool in summer, keep warm in winter, can reduce heat loss greatly, is used in buildings with heating equipment, and is an environmentally friendly material.

3. PC sunlight panels face troubles

Although the PC sunshine board has so many advantages, everything has two sides, there are advantages necessarily also have shortcomings. For example, service life is the most concerning issue.

Due to the special and single nature of the molecular structure of PC material, the surface hardness and tear resistance of PC board is poor, easy to be scratched by metal burrs, and easy to be scratched in production, transport, and installation, thus affecting the quality and service life of the products. Moreover, the PC board is often used to make high-quality products, such as monitors, mobile phone screens, etc., so it is also necessary to protect the surface from scratches and other violations.

4. How to improve the scratch resistance of the PC board?

Adding scratch-resistant silicone masterbatch-modified PC materials can effectively improve the scratch resistance of the PC.

Scratch-resistant silicone masterbatch and PC resin are blended, and the blended PC material is processed and molded through injection molding, extrusion, and other processes to obtain the final PC products. Adding scratch-resistant silicone masterbatch can improve the scratch resistance of the PC. Silicone masterbatch also has a certain lubricating effect, which can reduce the PC material friction, and reduce the occurrence of scratches.

5. SILIKE LYSI series product – the perfect scratch-resistant solution

SILIKE Anti-scratch Masterbatch LYSI-413 is a pelletized formulation with 25% ultra-high molecular weight siloxane polymer dispersed in Polycarbonate ( PC ). It is widely used as an efficient additive for PC-compatible resin systems to improve the processing properties and surface quality, such as better resin flow ability, mold filling & release, less extruder torque, lower coefficient of friction, and greater mar and abrasion resistance.

Compared to conventional lower molecular weight Silicone / Siloxane additives, like Silicone oil, silicone fluids, or other type processing aids, SILIKE Silicone Masterbatch LYSI series are expected to give improved benefits, eg, Less screw slippage, improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

Small amounts of SILIKE Anti-scratch Masterbatch LYSI-413 have the following advantages:

(1) Improve processing properties including better flow ability, reduced extrusion die drool, less extruder torque, and better molding filling & release.

(2) Improve surface quality like surface slip and lower Coefficient of friction.

(3) Greater abrasion & scratch resistance.

(4) Faster throughput, reduce product defect rate.

(5) Enhance stability compared with traditional processing aids or lubricants.

SILIKE Anti-scratch Masterbatch LYSI-413 has a wide range of applications for PC sheets, household appliances, electric and electronic parts, PC/ABS alloys, and other PC-compatible plastics.

It should be noted that when adding silicone masterbatch to modify PC materials, the proportion of addition should be determined according to the specific needs, as well as adequate process verification and testing to ensure that the modified PC materials can meet the required scratch resistance properties. How do you want to improve the scratch resistance of PC materials, please contact us, SILIKE will provide you with the perfect solution.

Post time: Jan-26-2024