Composite Packaging Film is two or more materials, after one or more dry laminating processes and combined, to constitute a certain function of the packaging. Generally can be divided into the base layer, functional layer, and heat sealing layer. The base layer mainly plays the role of aesthetics, printing, and moisture barrier, such as BOPP, BOPET, BOPA, etc.; the functional layer mainly plays the role of barrier, light, and other functions, such as VMPET, AL, EVOH, PVDC, etc.; the heat sealing layer in direct contact with the packaged goods, adaptability, resistance to penetration, good sealing, as well as transparency and other functions, such as LDPE, LLDPE, MLLDPE, CPP, EVA, etc.

Composite Packaging Film applications in a wide range of fields can be used for industrial packaging, daily packaging, food packaging, medicine and health, electronics, aerospace, science and technology, military, and other fields. But composite packaging bags have a very common and difficult-to-solve problem, that is, the bags have white powder precipitation, which has a huge negative impact on the composite packaging industry, Solving this problem has become the industry’s top priority.

Solving the Challenge of White Powder Precipitation in Food Packaging Bags: A Case Study in Composite Packaging Film:

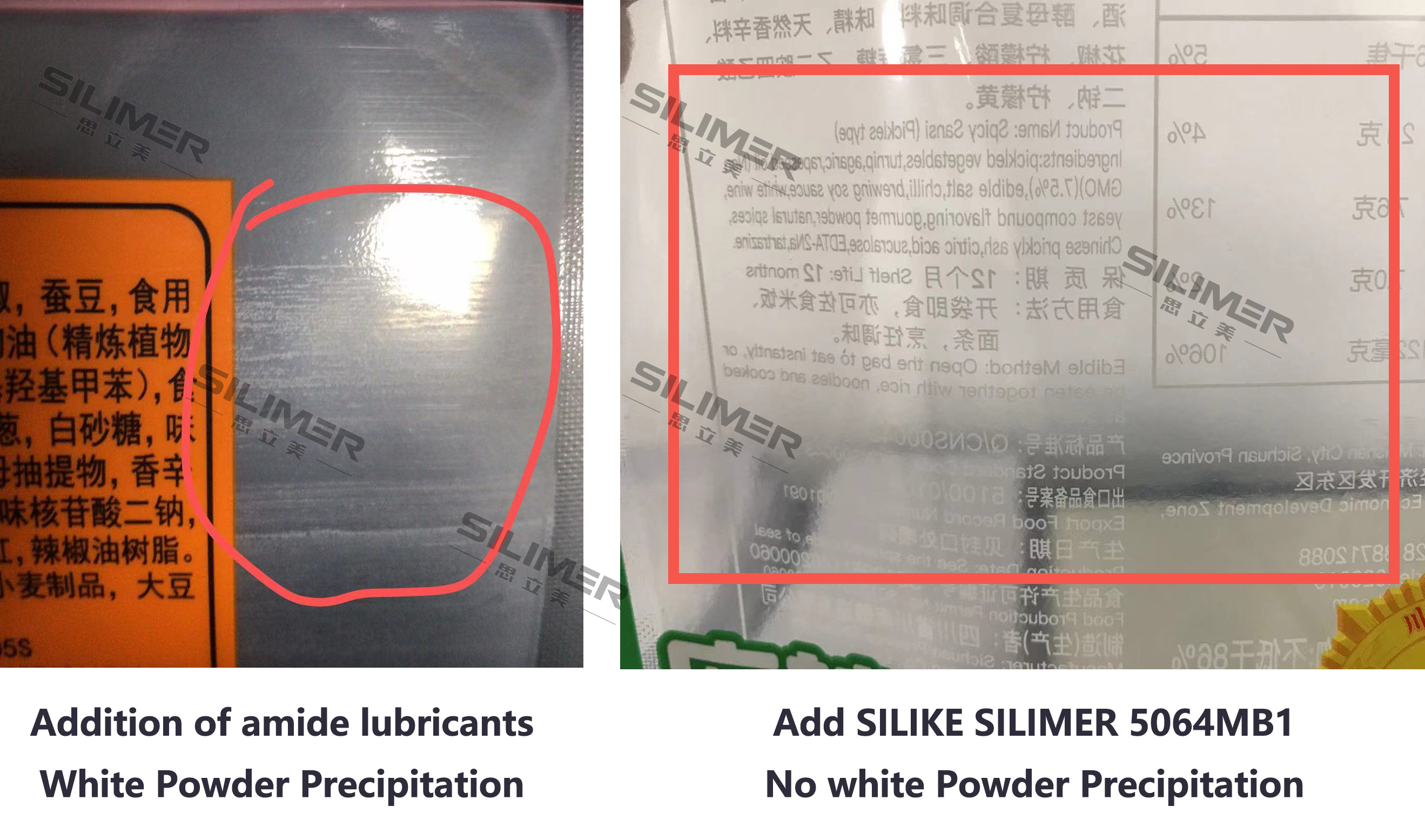

There is a customer who is doing composite packaging film, the amide additives he used before caused obvious white powder precipitation on the composite bags, which seriously affected the processing and the quality of the final product. More importantly, the composite packaging bags he produced are used for food packaging, due to the obvious white powder precipitation on the bag will be in direct contact with food, but also affects food safety. So the precipitation of white powder on the bags is very disturbing for this customer. However, the reason is because of the low molecular weight of the amide additives, and thermal stability is poor, with the time and temperature changes migrating to the film surface layer to eventually form a powder or wax-like substance, which leads to obvious white powder precipitation on the composite bags.

To address this challenge, SILIKE introduced the SILIMER series of Super-slip Masterbatch. Specifically, SILIMER 5064MB1, a super-slip masterbatch with a unique molecular structure containing copolymerized polysiloxanes with active organic functional groups, emerged as a game-changer in Composite Packaging Film.

Because of its small molecular weight, low surface energy, easy to migrate to the surface of plastics and parts, and molecules with active functional groups can play an anchoring role in plastics, to achieve the effect of easy to migrate without precipitation.

Feedback of SILIMER 5064MB1 has been positive, since the launch, add a small amount of SILIKE SILIMER 5046MB1 to the heat sealing layer, can significantly improve the anti-blocking &smoothness of the film, and the lubrication during processing can greatly reduce the film surface dynamic and static friction coefficient, making the film surface smoother, eliminating white powder precipitation on the surface of composite flexible packaging bags used in food packaging. One more highlight is the surface of the film has stable smooth performance nder high-temperature conditions or before and after the cure, does not affect printing, heat sealing, transmittance, or haze.

SILIKE Super-slip masterbatch SILIMER 5064MB1 is mainly used in BOPE films, CPE films, oriented flat film applications, and other composite packaging film products.

For manufacturers facing similar problems with composite packaging film for food packaging bags, SILIKE recommends trying SILIMER 5064MB1 for a sample test.

This innovative Super-slip Masterbatch not only addresses the white powder precipitation issue but also enhances overall processing performance, reducing defects and costs.

Throw your old amide slip additive, and contact SILIKE to explore how this innovative Super-slip Masterbatch solution can elevate the quality and safety of your composite packaging film products!

Post time: Dec-13-2023