Understanding Fiber and Monofilament:

Fiber and Monofilament are single, continuous strands or filaments of a material, typically a synthetic polymer like nylon, polyester, or polypropylene. These filaments are characterized by their single-component structure, as opposed to multifilament yarns that consist of multiple strands twisted or grouped together.

Fiber and Monofilament find applications in various industries, including textiles, fishing, and industrial processes. In textiles, monofilament yarns can be used for applications such as sheer fabrics, nets, and mesh. In fishing, monofilament lines are commonly used for angling and commercial fishing due to their strength, flexibility, and resistance to abrasion. monofilament is also used in the context of medical sutures, where single strands of biocompatible materials are used for stitching wounds or surgical incisions.

Usually, In the dynamic realm of polymer processing, the quest for efficiency and quality in fiber or monofilament extrusion is relentless. Manufacturers strive for innovative solutions to boost production performance, cut downtime, and reduce waste. this crucial manufacturing process converts polymer resins into continuous strands customized for a variety of applications, ranging from textiles and medical sutures to industrial components

Challenges in Fiber and Monofilament Extrusion:

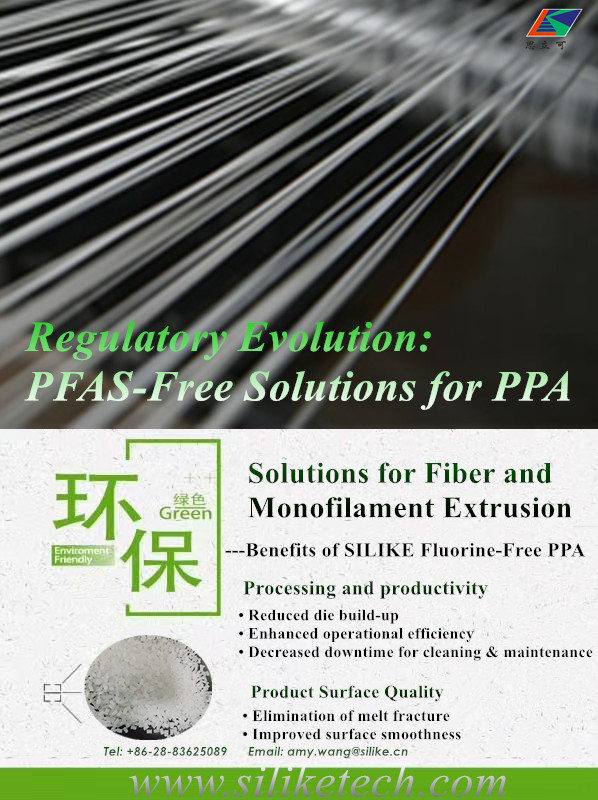

Die buildup, screen pack fouling, and strand breakage pose hurdles for manufacturers, impacting end-product quality and increasing downtime and costs. Traditional fluoropolymers and PFAS-containing chemicals have been used as efficient polymer processing aids (PPAs), But, as the looming new regulations in Europe and the USA impose limitations and bans on the use of fluoropolymers, and PFAS-containing chemicals, manufacturers seek alternatives that comply with these upcoming regulations without compromising performance.

SILIKE’s PFAS-Free PPA Solution:

SILIKE’s PFAS-free Polymer Processing Aids emerge as a groundbreaking solution to the challenges faced. Fluorine-Free Polymer Processing Aids(PPA)SILIMER 5090 aligns with upcoming EU regulations, navigating away from limitations and bans on fluoropolymers and PFAS-containing chemicals.

our groundbreaking solution ensures responsible polymer manufacturing, prioritizing sustainability without compromising quality or efficiency.

Typical applications that benefit from the use include:

• Blown and cast film

• Multilayer film extrusion

• Cable & Pipe extrusion

• Fiber and Monofilament Extrusion

• Petrochemical processing

• Sheet extrusion

• Compounding

Unlocking the Path to Optimal Fiber and Monofilament Extrusion!

In the realm of narrow dies and high volumes producing ultra-thin fibers, die and screen pack buildup, die plugging, and strand breakage pose challenges leading to waste and downtime. How does address Fiber and Monofilament Extrusion Challenges?

Unlock Efficiency in Fiber and Monofilament Production with SILIKE’s PFAS-Free PPA!

1. Die and Screen Pack Buildup Reduction: The innovative formulation of SILIKE Fluorine-Free Polymer Processing Aids(PPA)SILIMER 5090 effectively minimize the accumulation of impurities and polymer residues in narrow dies and screen packs. This reduction ensures a smoother extrusion process and prevents the need for frequent cleaning and maintenance.

2. Die Plugging Prevention: The unique formulation of SILIKE Fluorine-Free Polymer Processing Aids(PPA)SILIMER 5090 helps prevent die plugging, a common issue that disrupts the continuous flow of polymer through the die. This leads to more consistent extrusion and higher-quality end products.

3. Strand Breakage Mitigation: By enhancing polymer flow properties,SILIKE Fluorine-Free Polymer Processing Aids(PPA)SILIMER 5090 contribute to reducing strand breakage during extrusion. This not only improves production efficiency but also minimizes waste, resulting in cost savings for manufacturers.

4. Cost-Efficiency and Downtime Reduction: The combination of reduced die and screen pack buildup, prevention of die plugging, and mitigation of strand breakage collectively contribute to significant cost savings and reduced downtime. Manufacturers can achieve higher production volumes with improved efficiency.

Ready to elevate your extrusion processes? Explore the potential of SILIKE’s PFAS-free Polymer Processing Aids SILIMER 5090 for peak performance in fiber and monofilament production.

But that’s not all – Discover the Boundless Applications of SILIKE Fluorine-Free Polymer Processing Aids(PPA)SILIMER 5090 beyond Fiber and Monofilament Extrusion, From Blown film, cast film, Cable, pipes, Fiber, and Monofilament Extrusion, Sheet extrusion, Compounding to petrochemicals, metallocene polypropylene, or metallocene PE.SILIKE’s PFAS-free Polymer Processing Aids is your key to excellence Compliance Meets Innovation, aligns with upcoming EU regulations, steering clear of limitations and bans on fluoropolymers and PFAS-containing chemicals. This groundbreaking solution ensures responsible polymer manufacturing without compromising quality or efficiency, promising numerous production benefits.

Connect with SILIKE today to enhance your polymer processing, boost productivity, and elevate product quality!

Tel: +86-28-83625089 Email: amy.wang@silike.cn

Website: www.siliketech.com

Post time: Jan-10-2024