What is WPC lubricant?

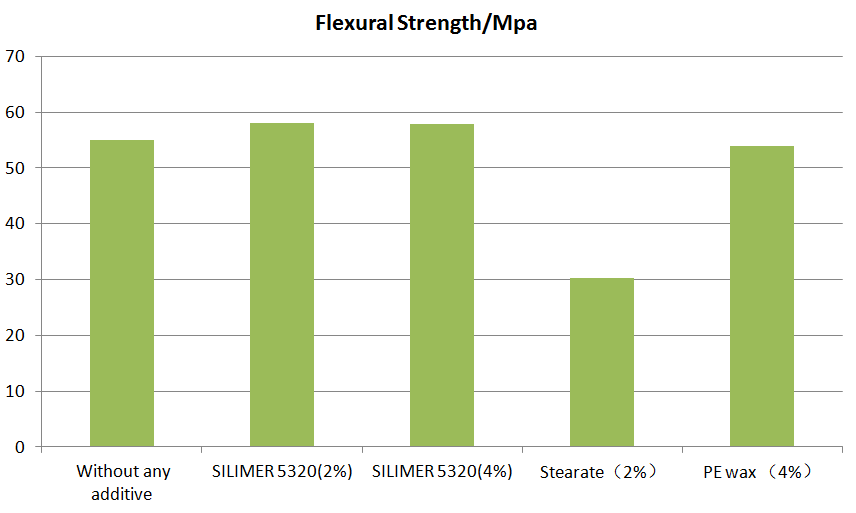

WPC processing additive (also called Lubricant for WPC, or release agent for WPC) is the lubricant dedicated to the production and processing of wood-plastic composites (WPC): Improve the processing flow performance, improve the appearance quality of products, ensure the physical properties of products, reduce the friction between polymer compounds and processing machinery, reduce equipment wear, and the extrusion molding is smooth. The quality of lubricant additive for WPC has a great impact on the service life of mold, barrel and screw in wood plastic processing, the production capacity of extruder, energy consumption in the production process, the surface finish of products and the low temperature impact performance of profiles. And if adding stearate in wood processing aid with MAH will weaken the crosslinking effect of maleic anhydride, crosslinking agent and lubricant efficiency will therefore be reduced.

The selection of lubricant solution for WPC considers the following requirements:

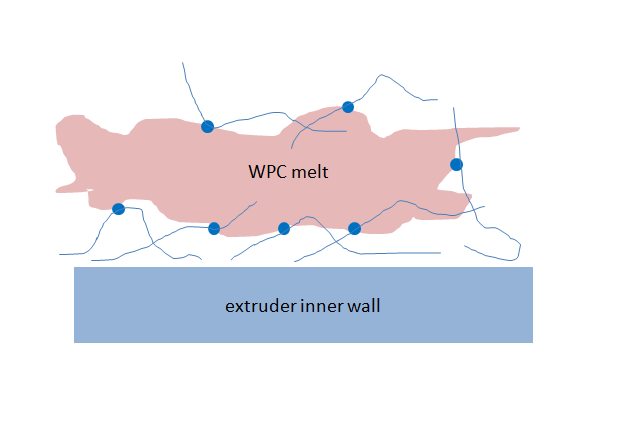

It has good compatibility with resin at high temperature, can produce a certain plasticizing effect, reduce the cohesion energy between molecules in resin, weaken molecules

, the friction between each other, reduce the melting viscosity of resin, improve the melting flow, promote the sliding of resin particles.

WPC products include many applications, these all will use lubricant during production for better surface quality of decking, sidings, wall cladding applications to improve processing performances and give better surface quality, etc.

Best WPC lubricant should be multi-functional, the purpose is to make processing equipment play the best operating characteristics, increase production, and improve the quality of products:

1、 Molecular interactions of polymers/polymers

2、Accelerate the plasticizing effect;

3、 Reduce melt viscosity;

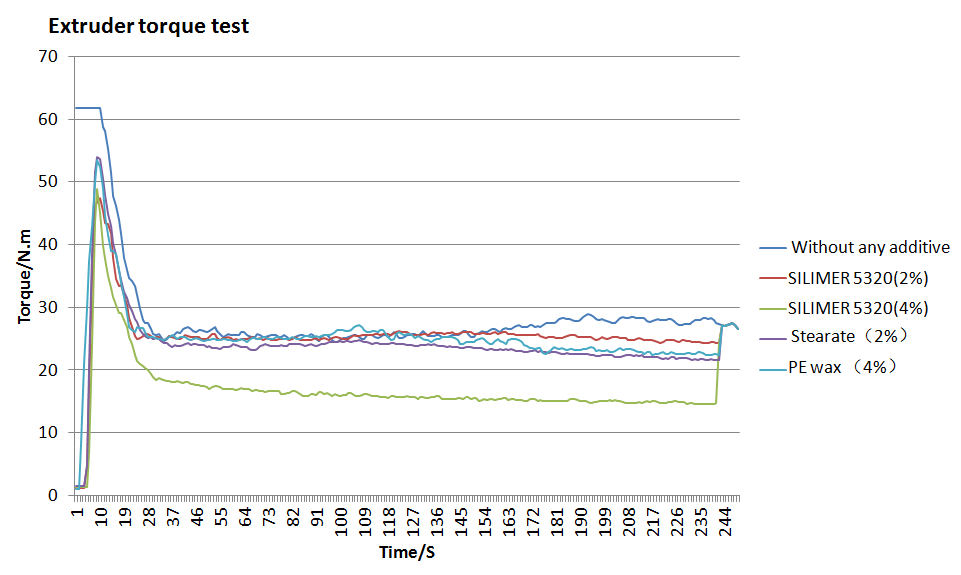

4、 Reduce torque and energy consumption;

5、 Polymer/filler interface interaction

6、 Promote the dispersion of wood powder or natural fiber filler;

7、 Contribute to the wetting of the filler;

8、 Lubricated filled polymer and heated or cooled metal interface;

9、 Improve the demolding property of the material in the extrusion bucket and the die surface;

10、 Reduce friction and wear;

11、 Providing Internal& External lubrication for WPC products

There are a lot of different wood plastic lubricants such as silicone-based lubricant SILIKE Silimer 5400, ethylene bis-stearamide (EBS), zinc stearate, paraffin waxes, and oxidized PE. And what are the wpc lubricants differences? Molecular weight, dosage, performances are different impacting factors with different performances. Silicone-based lubricants are highly resistant to wear and tear, as well as heat and chemicals. They are also non-toxic and non-flammable, making them an ideal choice for many applications. Silicone-based lubricants can also reduce friction between moving parts, which can help extend the life of the WPCs.

What is about the dosage of wood plastic lubricant?

Generally speaking, wood plastic composites (WPC) use twice as much lubricant as ordinary plastics. For wood plastic composites with wood fiber content of 50%~60%, the lubricant amount of HDPE based material is 4%~5%, the lubricant amount of PP based material is 1%~2%, and the lubricant amount of PVC based material is 5%~10%. However, the actual dosage may be adjusted according to the different formulations and processes of enterprises. SILIKE silimer 5400 will give better performances with smaller dosage with 1.5%~3%.

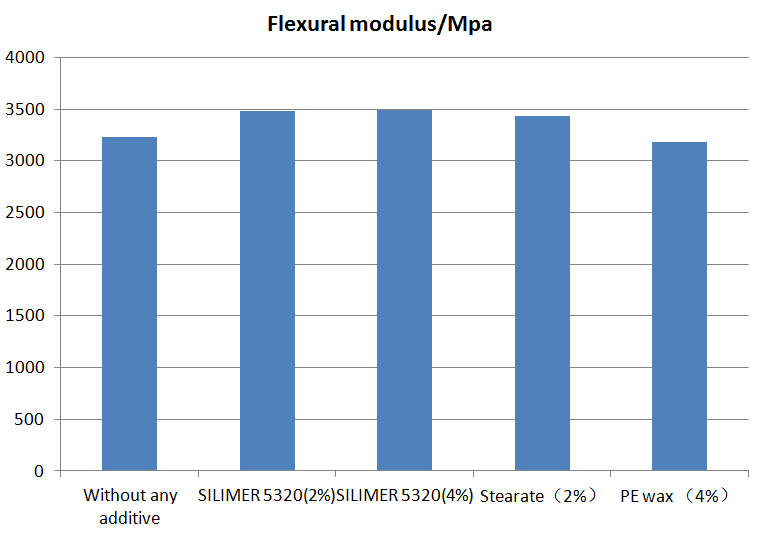

Chengdu Silike Technology Co.,LTD is a China WPC lubricant manufacturer to provide silicone-based lubricant for WPC. This lubricant additive is specially developed for the processing and production of PE WPC and PP WPC (wood plastic materials) such as WPC decking, WPC fence, and other WPC composites, etc. The core component of this lubricant solution for WPC is modified polysiloxane, containing polar active groups, excellent compatibility with resin and wood powder, in the process of processing and production can improve the dispersion of wood powder, does not affect the compatibility effect of compatibilizers in the system, can effectively improve the mechanical properties of the product. This release agent for WPC composites gives more performances than ethylene bis-stearamide (EBS), zinc stearate, paraffin waxes, and oxidized PE, and this lubricant is cost-effective with excellent lubrication, can improve the matrix resin processing properties, but also make the product smoother, give your wood plastic composites a new shape.

This Best WPC lubricant Silimer 5400 gives a lot of benefits with as below:

1、 Improve processing, reduce extruder torque, improve filler dispersion;

2、 Give internal&external lubricant for WPC, reduce energy consumption and increase production efficiency;

3、 Good compatibility with wood powder, does not affect the forces between the molecules of the wood plastic composite and maintains the mechanical properties of the substrate itself;

4、 Reduce amount of compatibilizer, reduce product defects, improve appearance of wood plastic products;

5、 No precipitation after boiling test, keep long-term smoothness.

Innovate silicone, Empowering new value.

Post time: Jun-09-2023