As global regulations on PFAS-based polymer processing aids (PPAs) tighten, polyethylene (PE) blown film and multilayer film manufacturers face increasing pressure to transition to safer, high-performance, and environmentally compliant alternatives. Forward-thinking companies are already positioning themselves ahead of the curve by adopting PFAS-free solutions early.

To support film producers in maintaining processing efficiency while meeting emerging PFAS restrictions across the EU, the U.S., India’s FSSAI, and other regulatory bodies, SILIKE has introduced the SILIMER Series fluorine free PPA product. This PFAS-free PPA technology features a modified copolysiloxane molecular structure, combining the low surface energy of silicone with polar groups that actively migrate to metal surfaces. Unlike fluoropolymer PPAs, SILIMER Series delivers comparable processing performance without the environmental or health concerns associated with PFAS compounds, helping manufacturers improve sustainability, ensure regulatory readiness, and remain competitive.

What Are PFAS-Free Polymer Processing Aids?

PFAS-free PPAs are next-generation additives designed to enhance melt flow, reduce melt fracture, prevent sharkskin, and minimize die buildup during polymer extrusion—without using PFAS-based chemistries. They provide similar processing benefits while complying with increasingly strict global regulations on fluorinated materials.

Why the Blown Film Industry Is Moving Toward PFAS-Free Alternatives

The industry shift is driven by growing environmental and health concerns, including contamination, bioaccumulation, and potential cancer risks. With regulations such as EU REACH, the US EPA PFAS Action Plan, and state-level bans, manufacturers are accelerating the adoption of safer, sustainable PFAS-free solutions to ensure compliance and maintain high-quality film production.

Polymers Manufacturers’ Favorite PFAS-Free Processing Aids Supplier

Introducing PFAS-Free PPA Manufacturer in China — SILIKE Non-PFAS PPA Solutions

SILIKE’s R&D team has developed the SILIMER Series, offering a full range of PFAS-free polymer processing aids (PPAs) — including 100% PFAS-free additives, fluorine-free masterbatches, pure fluorine-free PPAs, and PTFE-free additives. These solutions effectively reduce PFAS-related risks while improving processing efficiency across a wide range of industrial applications, including:

→ Polyolefins and recycled polyolefin resins

→ Blown, cast, and multilayer films

→ Fibers and monofilament extrusion

→ Cable and pipe extrusion

→ Masterbatch production

→ Polymer compounding

→ And more…

SILIKE PFAS-Free Polymer Processing Additives For Film Extrusion Solutions

Within the SILIMER family, SILIMER 5090 and SILIMER 9101 stand out as fluorine-free PPA additives specifically engineered for PE blown film and multilayer film extrusion lines.

SILIMER 5090 and SILIMER 9101 serve as high-performance polymer processing aids for blown-film extrusion and multilayer PE film processing.

Why the Packaging Industry Is Moving Toward SILIKE PFAS-Free PPAs

Key Technical Benefits of Sustainable Additives for Polyethylene Film Extrusion

SILIKE PFAS-free PPAs enable stable, high-performance polyethylene film extrusion while supporting sustainability goals. These advanced additives:

• Eliminate melt fracture and sharkskin, ensuring smooth film surfaces

• Reduce die buildup, minimizing downtime and extending cleaning intervals

• Boost throughput and optimize line speed for greater production efficiency

• Enhance processing stability by improving melt flow and reducing torque fluctuations

Fully compatible with printing, corona treatment, lamination, and sealing, SILIKE PFAS-free PPAs maintain mechanical strength and sealing integrity, making them ideal for modern, regulation-compliant film production.

Applications of PFAS-Free PPA in Blown Film Extrusion

SILIKE’s PFAS-free PPA can be used in:

• Food packaging film

• Industrial packaging film

• Courier & e-commerce bags

• Agricultural films

• Stretch hood & shrink film

• Laminated films

• Protective film & hygiene packaging

This allows manufacturers to meet sustainability requirements without sacrificing performance.

Recommended Dosage & Processing Guide of PFAS-free PPA

Typical addition level of SILIMER Non-fluoro PPA for PE/LDPE/LLDPE/mLLDPE Films: 0.5% – 2%, depending on resin grade and extrusion conditions

Can be directly blended with PE resins or masterbatches

Suitable for mono-layer and multi-layer blown film

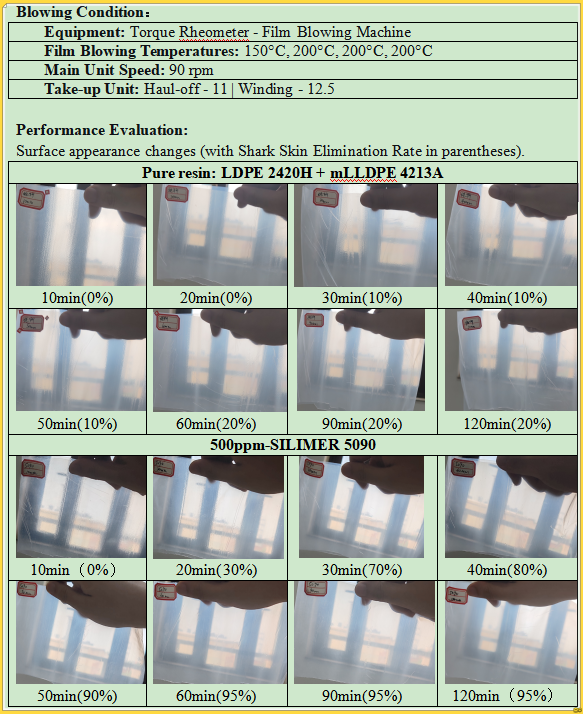

Case Study: How PFAS-Free PPA SILIMER 5090 Eliminates Melt Fracture & Sharkskin in Blown Film Lines

(Blown film lines using SILIMER 5090 showed significant reduction in melt fracture&Sharkskin , smoother film surfaces, and more stable extrusion compared to pure resin.)

Frequently Asked Questions (FAQ)

1. Can PFAS-free PPA replace fluoro-based PPA directly?

Yes. SILIKE’s SILIMER PFAS-free PPA is engineered for direct replacement in most PE blown film applications.

2. Does PFAS-free PPA eliminate sharkskin?

Yes, it effectively reduces melt fracture in LLDPE and metallocene PE.

3. Will PFAS-free PPA affect printing or corona treatment?

No. SILIKE PPA is fully compatible with common surface treatments.

4. Is PFAS-free PPA suitable for food packaging?

Yes, depending on regional regulatory requirements.

5. Does it affect sealing strength?

No, sealing performance remains stable.

Best PFAS-Free PPA Supplier Information– Your Trusted PFAS-Free PPA Partner

SILIKE is a prominent Chinese manufacturer dedicated to enhancing the performance of plastics, rubber, and elastomers through our innovative silicone additives, surface modifiers, processing aids, and PFAS-free polymer processing solutions. With over 20 years of experience in research and development, we leverage advanced silicone modification technology along with robust application testing capabilities.

We are committed to supporting our clients with technical consultation, formulation optimization, sample evaluation, and comprehensive global logistics solutions.

We invite you to explore SILIKE’s PFAS-free processing aids for your blown-film extrusion lines. Contact us today for technical assistance or to request a sample, and let’s work together to elevate your polymer production quality.

Email: amy.wang@silike.cn

Tel: +86-28-83625089

Website: www.siliketech.com

Post time: Nov-19-2025