Effective Solutions To Floating Fiber In Glass Fiber Reinforced Plastic.

In order to improve the strength and temperature resistance of products, the use of glass fibers to enhance the modification of plastics has become a very good choice, and glass fiber-reinforced materials have become quite mature in the plastics industry. A large number of facts have also proved the good performance brought by glass fiber. However, glass fiber and plastic are two different materials, which naturally leads to compatibility problems.

Glass fiber exposure (or called floating fiber) is a direct reflection of the compatibility of the two, and will seriously affect the appearance of the product, resulting in product scrap. Glass fiber exposure is also a problem often encountered in the injection molding process of fiber-added materials and troubled many friends.

So how exactly does fiberglass exposure occur?

Fiber fillers are made by blending glass fibers with resin and granulating. Since the glass fiber is much less fluid than plastic, it will stay on the surface of the mold during processing, thus causing the glass fiber to be exposed. At the same time, glass fiber has the role of promoting crystallization, and PP and PA are crystalline materials. Crystallization fast cooling fast; cooling fast, glass fiber is difficult to be bound by the resin and cover, then it is easy to produce glass fiber exposed.

In the production of Glass Fiber Reinforced Plastic, there are various solutions to improve the phenomenon of “floating fiber”:

1. Consider the compatibility of glass fiber and matrix, surface treatment of glass fiber, such as adding some coupling agent and graft,

2. Increase the material temperature and mold temperature; high pressure and high speed; use rapid hot and cold molding technology (RHCM),

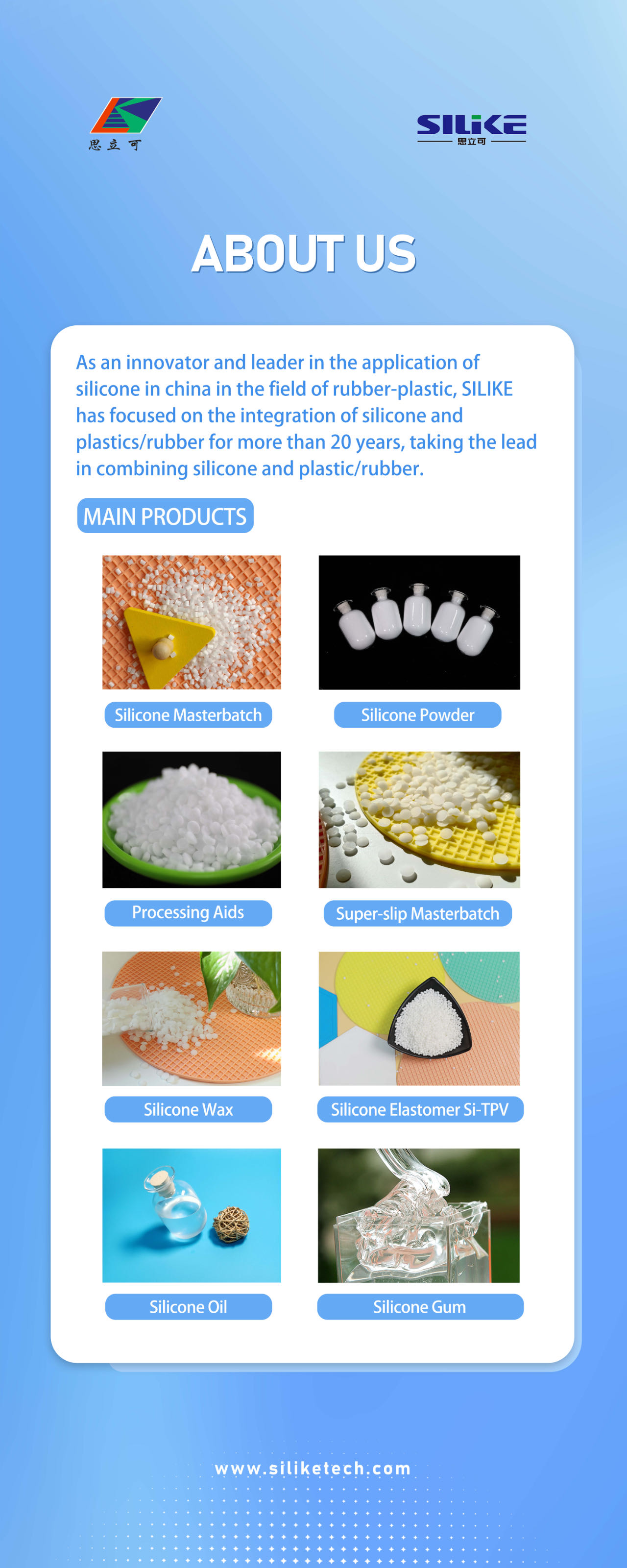

3. Add lubricants, these additives improve the interface compatibility between glass fiber and resin, improve the uniformity of the dispersed phase and continuous phase, increase the interface bonding strength, and reduce the separation of glass fiber and resin, thereby Improving the exposure of glass fiber. Silicone additive is considered the most effective lubricant. SILIKE Technology is an independent research and development production, trading combo Silicone additives in China, there are many grades of silicone additives, including Silicone Masterbatch LYSI Series, Silicone Powder LYSI Series, Silicone Anti-scratch masterbatch, silicone Anti-abrasion NM Series, Anti-squeaking Masterbatch, Super Slip Masterbatch, Si-TPV, and more, These silicone additives help to improve the processing properties of plastic materials and the surface quality of finished components.

Effective Solutions for Managing Fiber Migration in Glass Fiber Reinforced Plastics—SILIKE Silicone Powder to Improve Glass Fiber Exposure!

The use of SILIKE silicone powder in PA 6 with 30% glass fiber has been found to be beneficial, it can effectively reduce intermolecular friction, improve the fluidity of the melt, and promote the effective dispersion of glass fiber. At the same time, SILIKE silicone powder has good abrasion resistance, high-temperature thermal stability, and non-migratory properties. So, PA6 with 30% glass fiber in the process of high-temperature processing will not appear coking and precipitation of low molecular matter, to ensure that the surface gloss of the product, in the mobility increase, so that the glass fiber and PA6 can be melted at the same time to solve the problem of the wave fiber because of the melting of the glass fiber exposed phenomenon that occurs in time to the surface of the mold to run, additionally, Silicone powder can also help to reduce warping and shrinkage during manufacturing.

For more information about SILIKE Silicone Powder Resolving Floating Fiber Issues, or professional technical support, please contact us!

Post time: Sep-26-2023