In an era where safety standards and regulations are paramount, the development of materials that resist the spread of fire has become a critical aspect of various industries. Among these innovations, flame retardant masterbatch compounds have emerged as a sophisticated solution to enhance the fire resistance of polymers.

Understanding What are Flame Retardant Masterbatch Compounds?

Flame retardant masterbatch compounds are specialized formulations designed to impart fire-resistant properties to polymers. These compounds consist of a carrier resin, which is typically the same polymer as the base material, and flame retardant additives. The carrier resin serves as a medium for dispersing the flame retardant agents throughout the polymer matrix.

Components of Flame Retardant Masterbatch Compounds:

1. Carrier Resin:

The carrier resin forms the bulk of the masterbatch and is selected based on compatibility with the base polymer. Common carrier resins include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and other thermoplastics. The choice of carrier resin is crucial to ensure effective dispersion and compatibility with the target polymer.

2. Flame Retardant Additives:

Flame retardant additives are the active ingredients responsible for inhibiting or delaying the spread of flames. Basically, flame retardants can be either reactive or additive. These additives can be classified into various categories, including halogenated compounds, phosphorus-based compounds, and mineral fillers. Each category has its unique mechanism of action in suppressing the combustion process.

2.1 Halogenated Compounds: Brominated and chlorinated compounds release halogen radicals during combustion, which interfere with the combustion chain reaction.

2.2 Phosphorus-based Compounds: These compounds release phosphoric acid or polyphosphoric acid during combustion, forming a protective layer that suppresses the flame.

2.3 Mineral Fillers: Inorganic fillers like aluminum hydroxide and magnesium hydroxide release water vapor when exposed to heat, cooling the material and diluting flammable gases.

3. Fillers and Reinforcements:

Fillers, such as talc or calcium carbonate, are often added to improve the mechanical properties of the masterbatch compound. Reinforcements enhance stiffness, strength, and dimensional stability, contributing to the overall performance of the material.

4. Stabilizers:

Stabilizers are incorporated to prevent degradation of the polymer matrix during processing and use. Antioxidants and UV stabilizers, for instance, help maintain the material’s integrity when exposed to environmental factors.

5.Colorants and Pigments:

Depending on the application, colorants and pigments are added to impart specific colors to the masterbatch compound. These components can also influence the material’s aesthetic properties.

6. Compatibilizers:

In cases where the flame retardant and polymer matrix exhibit poor compatibility, compatibilizers are employed. These agents enhance the interaction between the components, promoting better dispersion and overall performance.

7.Smoke Suppressants:

Smoke suppressants, such as zinc borate or molybdenum compounds, are sometimes included to mitigate the production of smoke during combustion, an essential consideration in fire safety applications.

8. Additives for Processing:

Processing aids such as lubricants and dispersing agents facilitate the manufacturing process. These additives ensure smooth processing, prevent agglomeration, and assist in achieving uniform dispersion of flame retardants.

The above are all components of the flame retardant masterbatch compounds, while Ensuring the even distribution of flame retardants within a polymer matrix is a critical aspect of their efficacy. Inadequate dispersion can lead to uneven protection, compromised material properties, and reduced fire safety.

So, Flame retardant masterbatch compounds often require dispersants to address challenges associated with the uniform dispersion of flame retardant agents within the polymer matrix.

Especially In the dynamic realm of polymer science, the demand for advanced Flame Retardant materials with superior performance properties has spurred innovations in additives and modifiers. Among the trailblazing solutions, hyperdispersants have emerged as key players, addressing the challenges of achieving optimal dispersion in Flame Retardant Masterbatch compound formulations.

As hyperdispersants address this challenge by promoting the thorough and uniform distribution of flame retardants throughout the masterbatch compound.

Enter Hyperdispersant SILIKE SILIMER 6150—a class of additives that are reshaping the landscape of flame retardant formulations!

SILIKE SILIMER 6150, was developed to meet the polymer industry’s distinct needs, It is a modified silicone wax. As an efficient hyperdispersant, offers a solution to the challenges associated with achieving optimal dispersion and, consequently, optimal fire safety.

SILIKE SILIMER 6150 is recommended for the dispersion of organic and inorganic pigments and fillers, flame retardants in thermoplastic masterbatch, TPE, TPU, other thermoplastic elastomers, and compound applications. It can be used in a variety of thermoplastic polymers including polyethylene, polypropylene, polystyrene, ABS, and PVC.

SILIKE SILIMER 6150, Key benefit of flame retardant compounds

1. Improve flame retardant dispersion

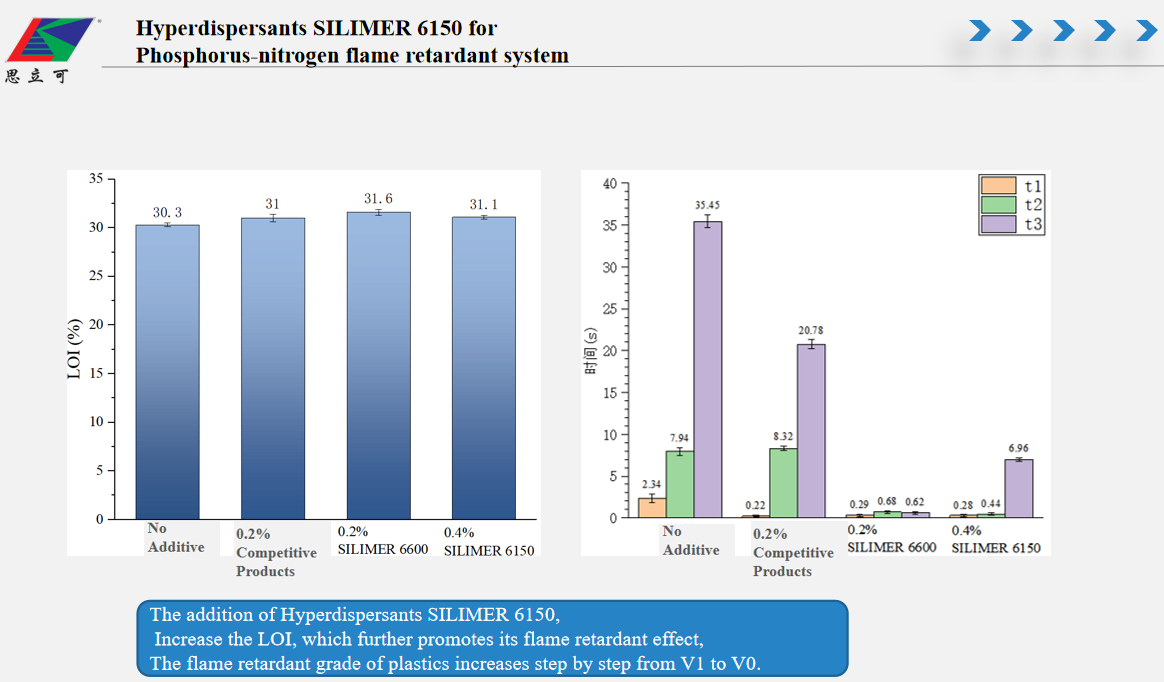

1) SILIKE SILIMER 6150 can be used together with the phosphorus-nitrogen flame-retardant masterbatch, effectively improving the flame-retardant effect of the flame retardant, Increasing the LOI, the flame retardant g.rade of plastics increases step by step from V1 to V0.

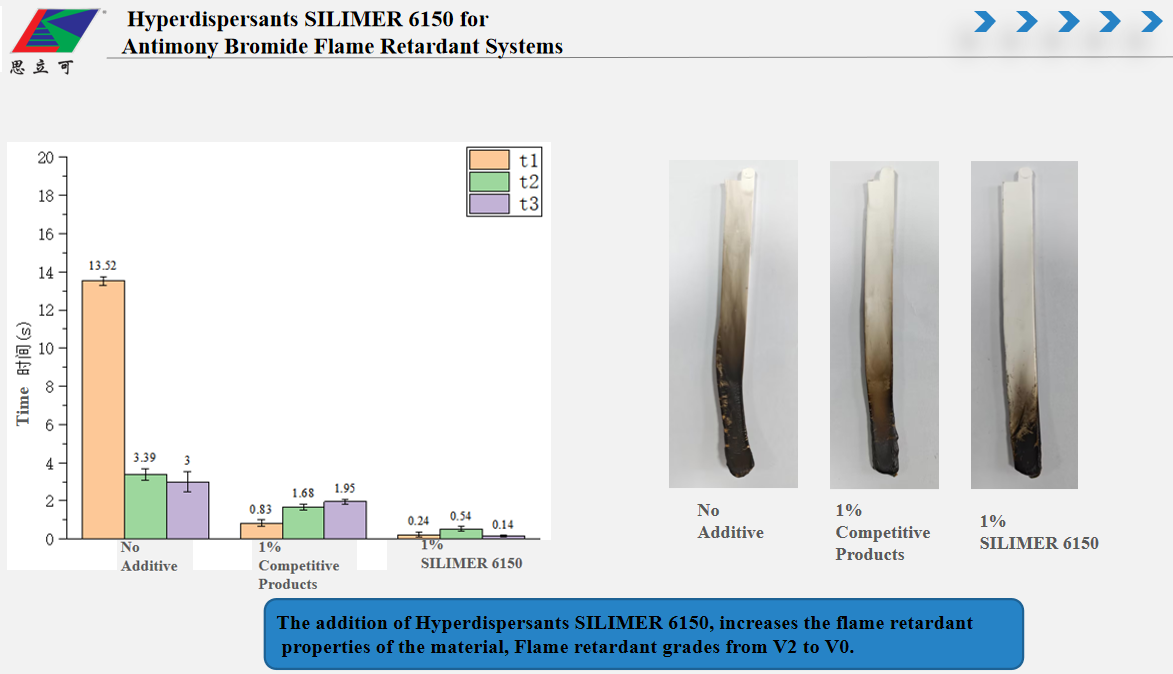

2) SILIKE SILIMER 6150 as well as has good flame retardant synergism with Antimony Bromide Flame Retardant Systems, Flame retardant grades from V2 to V0.

2 . Improve the gloss and surface smoothness of products ( lower COF)

3. Improved melt flow rates and dispersion of fillers, better mold release and processing efficiency

4. Improved color strength, no negative effect on mechanical properties.

Contact SILIKE to see how SILIMER 6150 Hyperdispersant can help formulators in making innovative flame retardant compounds and thermoplastics!

Post time: Oct-23-2023