Factory wholesale China Pellet PP/PE Anti-Scratch Masterbatch Modifier,

Factory wholesale China Pellet PP/PE Anti-Scratch Masterbatch Modifier,,

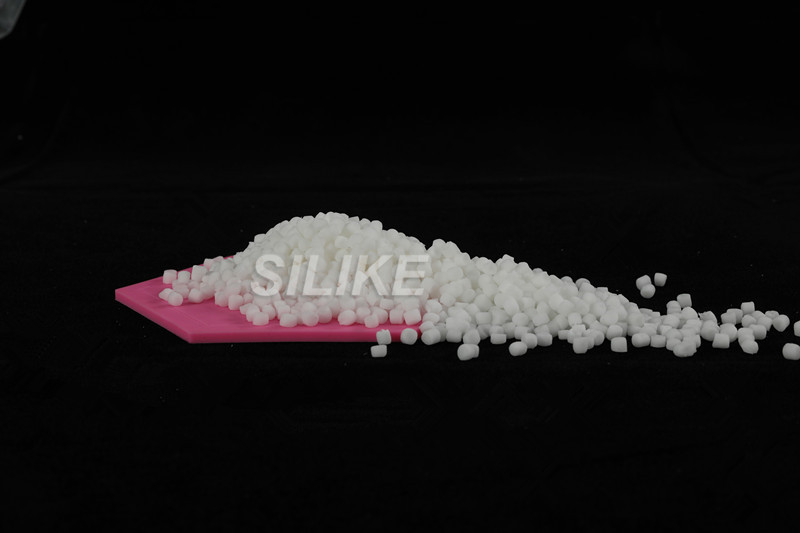

Anti-scratch additive, Silicone Masterbatch,

Description

Silicone masterbatch LYSI-306C is an upgraded version of LYSI-306, has an enhanced compatibility with the Polypropylene (CO-PP ) matrix — Resulting in lower phase segregation of the final surface, this means it stays on the surface of the final plastics without any migration or exudation , reducing fogging , VOCS or Odors . LYSI-306C helps improve long-lasting anti-scratch properties of automotive interiors , by offering improvements in many aspects like Quality, Aging , Hand feel, Reduced dust buildup… etc. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels.

Fundamental Parameters

|

Grade |

LYSI-306C |

|

Appearance |

White pellet |

|

Silicone content % |

50 |

|

Resin base |

PP |

|

Melt index ( 230℃, 2.16KG ) g/10min |

2 ( typical value ) |

|

Dosage% (w/w) |

1.5~5 |

Benefits

Silicone masterbatch LYSI-306C serves as both an anti-scratch surface agent and a processing aid . This offers controlled and consistent products as well as a tailor-made morphology.

(1) Improves the anti-scratch properties of TPE,TPV PP,PP/PPO Talc filled systems.

(2) Operates as a permanent slip enhancer

(3) No migration

(4) Low VOC emission

How to use

Addition levels between 0.5~5.0% are suggested . It can be used in classical melt blending process like Single /Twin screw extruders, injection molding. A physical blend with virgin polymer pellets is recommended .

Package

25Kg / bag , craft paper bag

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.Factory wholesale China Pellet PP/PE Anti-Scratch Masterbatch Modifier, We play a leading role in furnishing clients with good quality goods great provider.

Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we always have been focus on the production process

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

-

Phone

-

E-mail

-

WeChat

-

Top

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

1-300x199.jpg)