Transparent nylon (such as PA6, PA66, PA12, and copolyamides) is increasingly used in wire and cable applications where mechanical strength, heat resistance, electrical safety, and visual inspectability are all required. Typical examples include THHN, THHWN, BVN, and BVNVB cable jackets or insulation layers.

However, many compounders discover that once transparency is introduced, processing stability drops sharply.

Why Does Transparent Nylon Lose Flow and Surface Quality During Cable Extrusion?

In real production lines, transparent nylon cable compounds often suffer from:

• High extrusion pressure and unstable line speed

• Poor melt flow, especially at high filler or pigment loadings

• Surface roughness, die lines, or micro-scratches

• Transparency loss caused by thermal or shear stress

• Die buildup and frequent cleaning requirements

These issues directly affect productivity, appearance consistency, and cable reliability.

The Real Processing Challenges Behind Transparent PA6 / PA12

Unlike opaque nylon systems, transparent nylon relies on controlled crystallinity or amorphous molecular design. While this enables optical clarity, it also introduces processing sensitivity:

• Semi-crystalline regions respond strongly to shear and temperature

• Narrow processing windows increase viscosity fluctuation

• Conventional lubricants may migrate, bloom, or scatter light

• Internal friction rises, leading to higher torque and pressure

As a result, standard nylon processing aids often fail to deliver stable extrusion without sacrificing clarity.

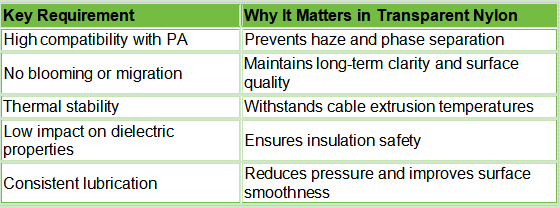

What Makes a Lubricant Suitable for Transparent Nylon Cable Compounds?

For wire and cable applications, a lubricant must solve processing problems without compromising optical or electrical performance.

Lubricants that fail in any of these areas may improve flow temporarily but bring some defects.

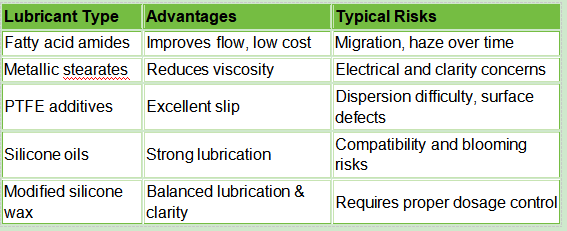

Comparison of Lubricant Types for Transparent Nylon Processing

Among these options, modified silicone waxes are increasingly favored for transparent nylon cable compounds due to their stability and compatibility.

How Modified Silicone Wax Solves These Issues in Practice

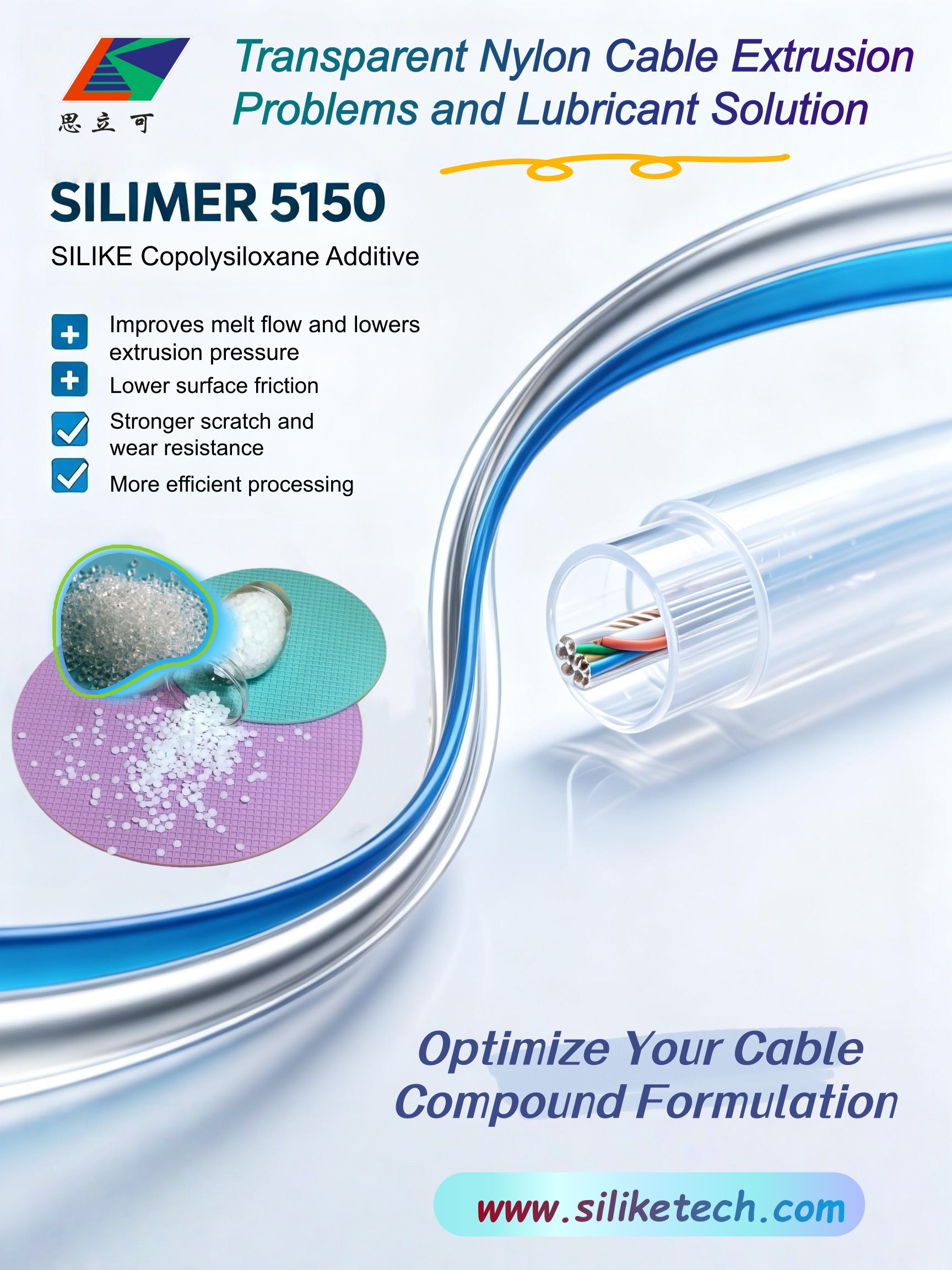

SILIKE SILIMER 5150 is a Copolysiloxane Additive and Modifier. Functionally modified silicone waxes are engineered with copolymer structures that interact more uniformly with nylon matrices. This allows them to:

√ Reduce internal and external friction simultaneously

√ Improve melt flow and mold or die filling

√ Minimize die buildup during long production runs

√ Preserve transparency and surface gloss

√ Enhance the scratch and abrasion resistance of finished cables

SILIKE SILIMER 5150 is one such modified silicone wax. As a silicone-based lubricant processing additive, it is designed to deliver high lubrication without precipitation, blooming, or optical loss. In transparent PA6, PA12, and copolyamide cable compounds, it helps stabilize extrusion while maintaining a smooth, clear surface finish.

When Should You Consider a Processing Additive Silicone Wax Lubricant Like SILIMER 5150?

This type of lubricant processing additive is particularly suitable when:

√ High transparency must be maintained after extrusion

√ Extrusion pressure limits line speed

√ Surface scratches or die lines cause quality complaints

√ Long production cycles increase die buildup risk

√ Both mechanical durability and appearance are critical

In these applications, modified silicone wax additives provide a practical balance between processing efficiency and final cable performance.

FAQs About Lubricants for Transparent Nylon Cables

Does silicone wax affect electrical insulation performance?

When properly formulated, modified silicone waxes have minimal impact on dielectric properties and are widely used in cable insulation systems.

Will wax additives reduce transparency?

Compatibility is key. Modified silicone waxes designed for polyamides maintain clarity better than conventional waxes or migrating lubricants.

What is the typical dosage range of Copolysiloxane Additive and Modifier SILIMER 5150?

Most transparent nylon compounds use 0.5–1.0 wt%, depending on resin type and processing conditions.

Seeking formulation guidance or lubricant sample assistance to enhance melt flow and augment smoothness in transparent nylon cable compounds?

Regardless of whether it is employed in injection molding or extrusion, SILIKE Copolysiloxane Additive and Modifier SILIMER 5150 contributes to the reduction of processing defects, minimizes die deposition, and enhances scratch and abrasion resistance. Consequently, it emerges as an optimal selection for nylon – based applications that demand durability, a smooth surface finish, and high transparency.

Reach out to the SILIKE technical team for appropriate recommendations regarding modified silicone wax in polyamide (PA) processing and the improvement of surface properties (lubricity, slipperiness, lower friction coefficient, silky texture), as well as a sample of silicone – based additives for a surface finish enhancer for nylon materials.

Tel: +86- 28 – 83625089 or Email: amy.wang@silike.cn. Website: www.siliketech.com.

Post time: Jan-21-2026