Role of Plastics Additives in Enhancing Polymer Properties:Plastics influence every activity in modern life and many depend entirely on plastics products.

All these plastics products are made from the essential polymer mixed with a complex blend of materials,and Plastic additives are substances that are added to these polymer materials during their processing to enhance or modify their properties. Without Plastics additives, plastics would not work, but with them, they can be made safer, strong, colorful, comfortable, and beauty and practicality.There are several types of plastic additives available, each with its specific function. Here are some common categories:

Stabilizers: These additives help protect plastics from degradation caused by heat, light, or oxidation. They prevent color fading, brittleness, or loss of mechanical properties.

Plasticizers: Plasticizers increase the flexibility and workability of plastics. They reduce the brittleness and make the material more pliable and easier to process. Common plasticizers include phthalates.

Flame retardants: These additives improve the fire resistance of plastics by reducing their flammability and slowing down the spread of flames.

Antioxidants: Antioxidants prevent the degradation of plastics caused by exposure to oxygen, thus extending their lifespan and preserving their physical properties.

UV stabilizers: These additives protect plastics from the damaging effects of ultraviolet (UV) radiation, such as discoloration, degradation, or loss of strength.

Colorants: Colorants are additives that provide pigmentation to plastics, giving them a desired color or appearance.

Fillers: Fillers are additives used to modify the mechanical properties of plastics. They can improve stiffness, strength, and dimensional stability while reducing costs.

Lubricants: Lubricants are added to plastics to improve their processability by reducing friction during molding or shaping.

Impact modifiers: These additives enhance the impact resistance of plastics, making them less prone to cracking or breaking under stress.

Antistatic agents: Antistatic additives reduce or eliminate static electricity buildup on the surface of plastics, making them less likely to attract dust or cause electric shocks.

Processing additives: also known as process aids, are substances that are added to plastic materials during their manufacturing or processing stages to improve the handling, performance, or processing characteristics of the material.

These Processing additives are typically used in small quantities and can significantly impact the manufacturing process by enhancing material flow, reducing defects, improving mold release, and optimizing the overall production performance.

These are just a few examples of plastic additives. the selection and combination of additives depend on the specific manufacturing process, equipment, desired properties of the final plastic product, and the specific application it is intended for.

What do Additives Add to Plastics Polymer Materials?

Look here for special notes :

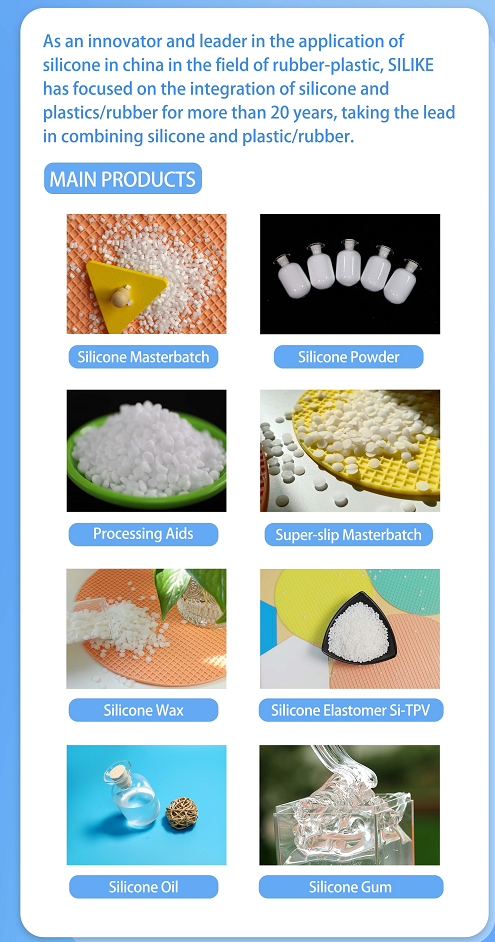

Silicone masterbatch is a kind of processing luricants additive in the rubber and plastic industry. The advanced technology in the field of silicone additives is the use of ultra-high molecular weight (UHMW) silicone polymer (PDMS) in various thermoplastic resins, such as LDPE, EVA, TPEE, HDPE, ABS, PP, PA6, PET, TPU, HIPS, POM, LLDPE, PC, SAN, etc. And as pellets so as to allow easy addition of the additive directly to the thermoplastic during processing. combining excellent processing at an affordable cost. that they are widely used in improved processing of plastics and surface quality of finished components for automotive interiors, cable and wire compounds, telecommunication pipes, footwear, film, coating, textile, electric appliances, papermaking, painting, personal-care supply, and other industries. it is honored as “industrial monosodium glutamate”.

Above all, SILIKE’s silicone masterbatch works as a highly efficient processing aids, It is easy to feed, or mix, into plastics during compounding, extrusion, or injection molding. It is better than traditional wax oil and other additives in improving slippage during production. due to silicone masterbatch’s ultra-high molecular weight, forming a lubricant layer between the plastics and extruders, dispersing evenly in the system, thus making plastics easier to process, such as faster extrusion speed, less die pressure, and die drool, larger throughput, easier mold filling, and mold release, etc.

Meanwhile, the surface quality of plastics can be improved, such as a lower coefficient of friction, super-slip hand feel, scratch resistance, abrasion resistance, dry & soft hand feel, etc.

How silicone masterbatch plastic additives can modify the physical, mechanical, and chemical properties of polymers?

kindly contact us to learn more about application technology!

e-mail:amy.wang@silike.cn

Post time: Jul-13-2023