Wire and cable plastics (referred to as cable material) are varieties of polyvinyl chloride, polyolefins, fluoroplastics, and other plastics (polystyrene, polyester amine, polyamide, polyimide, polyester, etc.). Among them, polyvinyl chloride, and polyolefin accounted for the vast majority of the dosage, the following is an introduction to the application of plastic additives in PVC and polyolefin cable materials and their influence on plastic properties.

Plastic is mainly composed of synthetic resin, which determines the basic performance of plastic materials. However the use of resin alone can not meet the special performance requirements of various wires and cables and processing performance requirements, must be added to a variety of plastic additives that can be made into a variety of cable materials to meet market requirements.

What are the processing aids in PVC cable materials? There are generally the following types of additives:

1、Plasticiser

Plasticiser is an important cooperating agent in PVC plastic for wire and cable. Plasticiser because it can play a solvent role between the polar groups in the molecular structure of polyvinyl chloride, the distance between the polyvinyl chloride molecules and play a role in balancing the release, so it can increase the plasticity, high-speed physical and mechanical properties, and improve the performance of the process.

2、Anti-oxygen agent

In order to prevent degradation and cross-linking of plastics during processing and long-term use due to the action of oxygen, antioxidants are often added to plastics, which is more important for heat-resistant PVC plastics.

3、Filler

Wire and cable with polyvinyl chloride plastic add filler purpose:

First, in order to reduce the cost of the product, play the role of incremental agent.

The second is to improve product performance.

4、Colouring agent

Polyvinyl chloride plastic coloring in addition to making products with bright colors, meets the needs of aesthetics, but also improves weather resistance, prolongs the service life of plastic communication cables and power cables, endowed with different colors of the core, thus facilitating the installation, use, and maintenance.

5、Flame retardant

The most effective flame retardant for PVC plastics is antimony trioxide (Sb2O3), and paraffin chloride is also effective, in addition, there are aluminum hydroxide, magnesium hydroxide, and phosphate plasticizers.

6、Lubricant

Although the amount of lubricant is small, it is an indispensable additive for PVC plastics. The addition of lubricant reduces the friction effect and the adhesion of the plastic to the metal surface of the processing equipment and also reduces the friction and heat generation effect between the resin particles and the resin macromolecules in the process of resin melting after melting.

7、Mixing modifier

Polyvinyl chloride can be modified by adding a polymer modifier to improve the performance of the products, so as to expand the scope of application.

SILIKE processing additives for wire and cables——The first choice for wire and cable compounds material processing aids!

Chengdu Silike Technology Co., Ltd——as an innovator and leader in the application of silicone in China in the field of rubber-plastic, Silike has focused on the integration of silicone and plastics for more than 20 years, taking the lead in combining silicone and plastic.

Our silicone additives are based on different resins to ensure optimum compatibility with the thermoplastic, Incorporating SILIKE LYSI series silicone masterbatch significantly improves the material flow, extrusion process, slip surface touch and feel, and creates a synergistic effect with flame-retardant fillers.

They are widely used as an efficient processing additive in LSZH/HFFR wire and cable compounds, silane crossing linking XLPE compounds, TPE wire, Low smoke & low COF PVC compounds.

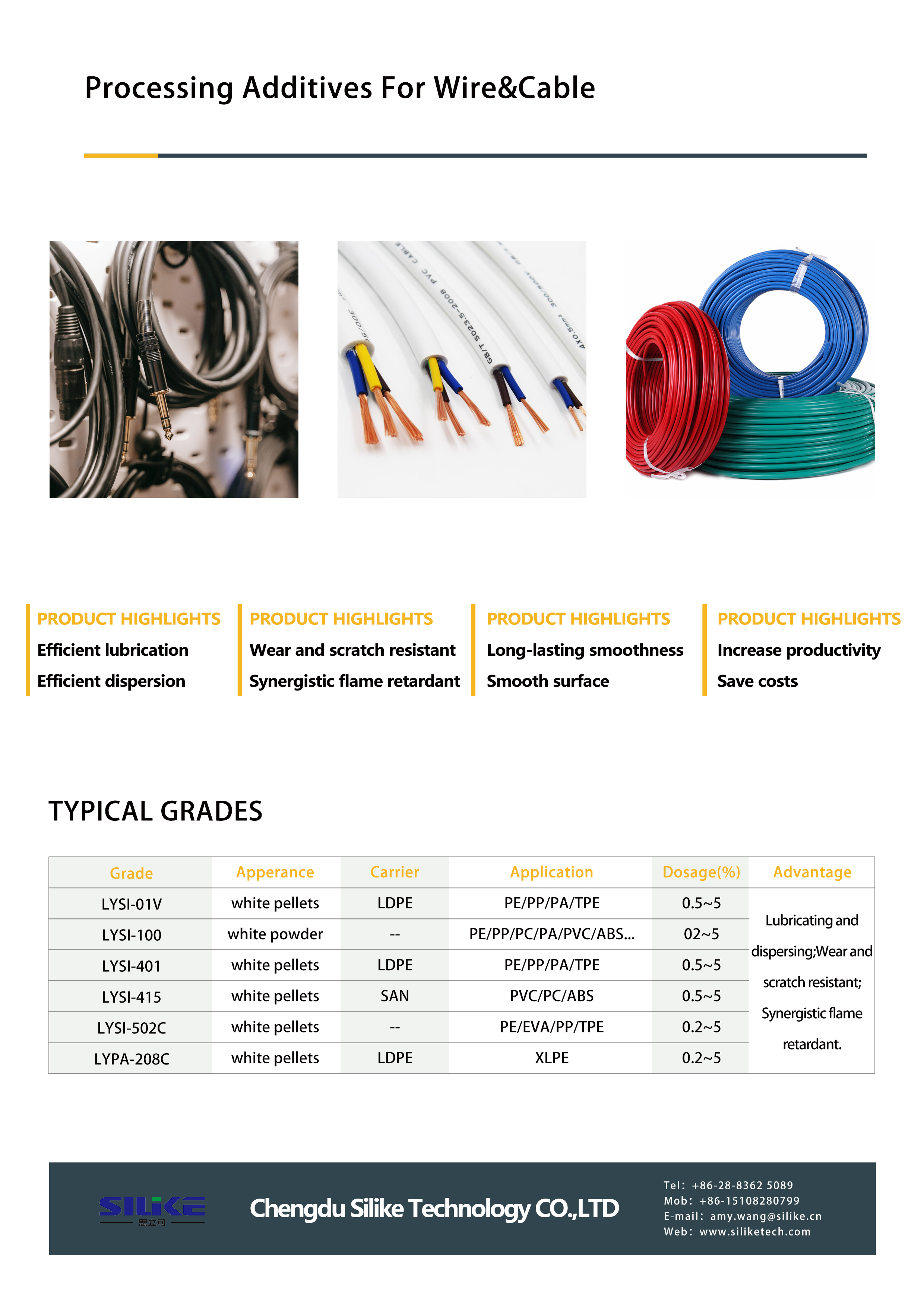

Compared to conventional lower molecular weight Silicone/Siloxane additives, like Silicone oil, silicone fluids, or other type processing aids, the SILIKE Silicone Masterbatch LYSI series are expected to give improved benefits as below:

1.Solve processing issues: significantly improve the material flow, Mold filling/release, Less screw slippage, optimize extrusion parameters, and reduce die drool.

2.Enhance surface properties: Like reducing COF, improving scratch & abrasion resistance, and better surface slip and hand feel…

3.Faster dispersion of flame retardant ATH/MDH.

4.Synergistic flame retardant effect.

Make your wire and cable products eco-friendly, safer, and stronger for better end-use performance.

Below is the product brochure of SILIKE processing additives for wire and cables, you can browse, if you have cable processing aids needs, SILIKE welcomes your inquiry!

Post time: Oct-26-2023