Facing High Torque, Die Drool, or Poor Flow in LSZH Cable Compounds?

Low Smoke Halogen-Free (LSZH) cable materials are increasingly vital for modern cable safety and sustainability. Yet, achieving excellent processability remains a challenge. The heavy use of flame-retardant fillers—such as aluminum hydroxide (ATH) and magnesium hydroxide (MDH)—often causes poor flowability, high torque, rough surface finishes, and die buildup during extrusion.

Why are LSZH Cable Compounds difficult to process?

The features of low-smoke halogen-free flame-retardant wire and cable are that all materials are halogen-free, and a very small amount of smoke will be released during combustion. In order to achieve these two key factors, a large number of flame retardants were added in the production process, which directly leads to a series of processing problems.

The following are common processing pain points of low-smoke halogen-free cable compounds:

1. Due to a large amount of flame retardant fillers like aluminum hydroxide and magnesium hydroxide added, which leads to poor flow ability, and friction heat generation during processing leads to temperature rise, which results in the degradation of aluminum hydroxide and magnesium hydroxide.

2. Low extrusion efficiency, and even higher extrusion speed, the extrusion capacity remains unchanged.

3. Due to poor compatibility of the polyolefins with flame retardants and other fillers, which results in poor dispersion during processing and reduced mechanical properties.

4. The uneven dispersion of inorganic flame retardants in the system leads to a rough surface and a lack of gloss during extrusion.

5. The structural polarity of flame retardant and other fillers causes the melt to adhere to the die head, delays the material demoulding, or the precipitation of low molecules in the formulation, which results in material accumulation at the die mouth, thus affecting the quality of the cable.

How to solve the LSZH cable these process issues and surface quality?

To overcome these issues, silicone masterbatch technology has become a trusted solution in LSZH compound formulations, improving both processing efficiency and surface performance without compromising mechanical or electrical properties.

Why is silicone masterbatch an effective solution for improving the processing and surface performance of LSZH cable compounds?

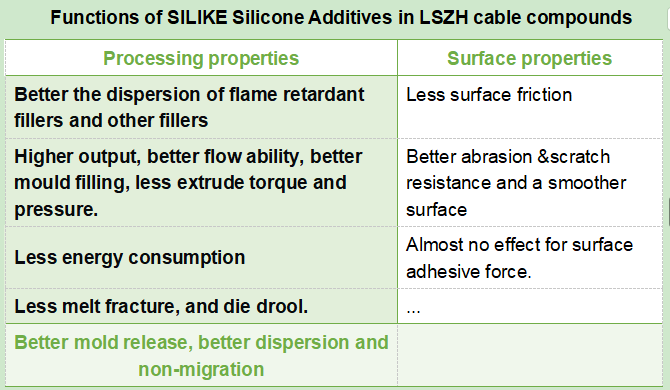

Silicone masterbatch is a kind of functional processing additive with various thermoplastics as carriers and polysiloxane as the functional parts. On the one hand, silicone based masterbatch can improve the flow ability of thermoplastic system during molten state, better the dispersion of fillers, reduce the energy consumption of extrusion and injection molding, and improve the production efficiency; On the other hand, this Silicone-based processing aid can also improve the surface smoothness of the final plastic products, reduce the surface friction coefficient and improve the wear and scratch resistance. In addition, as a processing aid for the thermoplastic industry, silicone masterbatch can achieve an obvious modification effect with a small amount (< 5%), without too much consideration of its reaction with the matrix material.

Chengdu Silike Technology Co., Ltd. is a leading Chinese manufacturer specializing in silicone-based additives for the plastics and rubber industries. With over 20 years of dedicated research focused on the integration of silicone and polymers, Silike has established itself as an innovative and trusted partner for high-performance additive solutions.

To assist manufacturers in navigating the production challenges related to LSZH cables, Silike has developed a comprehensive portfolio of silicone plastic additives specifically designed to enhance the processing of cable compounds. Noteworthy products, such as Silicone Masterbatch LYSI-401 and Silicone Masterbatch LYSI-502C, offer effective solutions aimed at improving processability and surface quality, thus contributing to superior performance in wire and cable applications.

Performance Benefits: Typical Test Results of Silicone Masterbatch in LSZH Cable Compounds

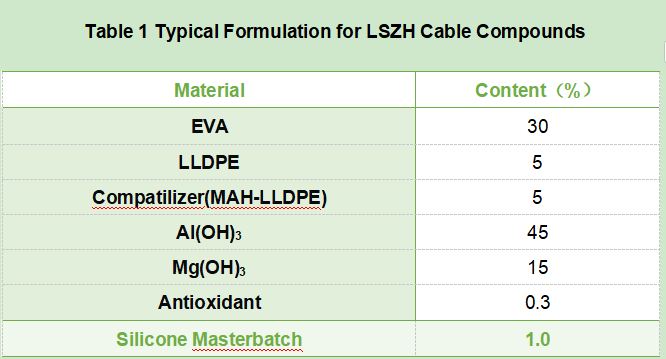

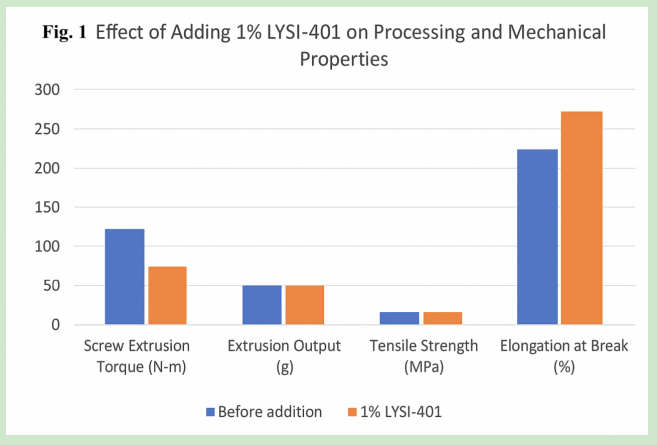

Adding SILIKE Silicone Masterbatch ( Siloxane Masterbatch ) LYSI series to the high flame-retardant filling system of low smoke halogen-free cable material can improve processing fluidity, reduce torque, and improve production efficiency. Figure 1 shows the test comparison of cable performance after adding 1% LYSI-401 silicone masterbatch in our company’s simulated general low smoke halogen-free formula (Table 1). It can be seen that the relevant performance has been significantly improved.

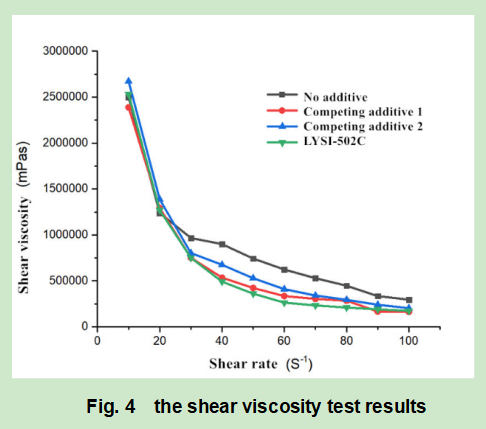

Fig.2 , Fig.3, and Figure 4 show the torque rheometer test of siloxane High Content Silicone masterbatch LYSI-502C added to the common low smoke halogen-free formula and the comparison with the torque, pressure, and shear viscosity of foreign competitive products. It can be seen that LYSI-502C has excellent lubrication performance.

Figure 5 provides a valuable simulation of material accumulation within a cable extrusion die following the addition of the silicone masterbatch. The results reveal that the inclusion of a standard silicone masterbatch significantly reduces die buildup. Furthermore, SILIKE’s high molecular weight silicone masterbatch showcases an even more pronounced effect in minimizing die buildup, indicating its potential for enhanced processing efficiency.

Summary: The siloxane present in standard silicone masterbatches is nonpolar, which can create challenges given the differing solubility parameters of most carbon chain polymers. When the addition is excessive, it may lead to issues such as screw slip, excessive lubrication, delamination of the product surface, compromised bonding performance, and uneven dispersion within the substrate.

To address these challenges, SILIKE has developed a series of ultra-high molecular weight silicone additives that are modified with specialized functional groups. These silicone-based polymer processing additives are designed to meet specific application requirements across various thermoplastic systems. By acting as anchors within the substrate, they enhance compatibility, improve dispersion, and strengthen adhesion. This results in significantly improved overall substrate performance. In low-smoke, halogen-free systems, these innovative additives effectively prevent screw slip and markedly reduce die material accumulation.

Are you searching for a polymer processing additive to enhance your LSZH cable manufacturing process?

Explore how SILIKE’s silicone-based masterbatch solutions, including the silicone additive LYSI-401 and the siloxane masterbatch LYSI-502C, can assist you in improving productivity, reducing die maintenance, and achieving superior cable quality. We invite you to contact us for further information and to request a sample.

Website: www.siliketech.com

Email: amy.wang@silike.cn

Post time: Oct-10-2025