Introduction: The Challenge of TPU Cable Jackets

TPU cable jackets are widely used in consumer electronics, wearable devices, and industrial cabling, offering flexibility, durability, and soft-touch aesthetics. However, manufacturers often face persistent challenges:

→ Matte surfaces turning glossy after extrusion

→ Micro-scratches appearing during winding or daily use

→ Blooming or additive precipitation reducing surface quality

→ Difficulty balancing surface appearance, wear resistance, and process efficiency

→ Achieving a stable matte finish while maintaining scratch and wear resistance is a top priority for R&D engineers in cable production.

TPU Engineers and TPU compound formulators frequently search for solutions to questions like:

How to improve matte effect in TPU compounds?

What additives enhance scratch resistance without affecting surface finish?

Why do TPU cable jackets bloom over time?

How to achieve a durable matte surface in high-performance TPU applications?

SILIKE Matt Effect Masterbatch — A High-Performance Solution for TPU Compounds in Cable Jackets

SILIKE Matte Effect Masterbatch 3135 is a high-value functional matte additive formulated with TPU as the carrier. This advanced mattifier enhances the matte appearance, surface texture, durability, and anti-blocking properties of TPU composites and finished products, particularly in cable jackets, films, and other applications.

Highlights of the Highly Effective Matting Agent for TPU Cable Jackets

1.Silky Soft Touch – Provides a premium tactile experience.

2.Wear & Scratch Resistance – Improves surface durability under mechanical stress.

3.Consistent Matte Finish – Maintains a refined matte appearance from production to end-use.

3.No Precipitation – Prevents blooming and additive migration, ensuring long-term clean surfaces.

Technical Principle-Matte effect TPU solutions for cable applications

SILIKE TPU Matt Masterbatch leverages silicone-modified surface engineering, optimizing micro-surface topology and friction coefficient. This modification ensures that the TPU matrix maintains:

Surface integrity during extrusion and bending

Soft-touch aesthetics without compromising mechanical strength

Long-term matte appearance even under thermal or mechanical stress

Application Guide for TPU Cable Formulations: High-Performance TPU Surface Optimization

→ TPU Soft-Touch Matte Formulation Guide – Typical Usage Recommendations:

Dosage: Optimized according to TPU grade and extrusion process (typically 1–10 wt%).

Mixing Method: Dry blending or pre-compounding with TPU pellets to ensure uniform distribution.

→ Processing Tips to Enhance TPU Processing and Surface Appearance:

Maintain consistent melt temperature to prevent surface gloss variations.

Adjust screw speed to minimize micro-scratches.

Case Study for TPU cable jackets matte and scratch-resistant solutions

TPU cable jackets compounded with SILIKE Matting Agents for TPU retained a stable matte finish and soft-touch feel after 6 months of continuous field testing, with no blooming and improved wear resistance.

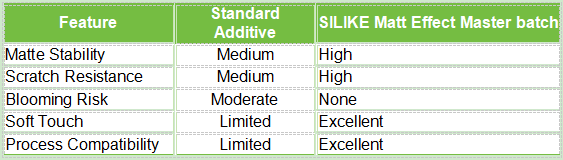

Comparison of Matt Effect Masterbatch with Other Additives

SILIKE Matte Effect Masterbatch not only solves common matte stability and scratch issues but also ensures process efficiency and product aesthetics.

FAQ: How to Optimize TPU Matte Formulations?

Q1: How to prevent gloss drift in TPU cable jackets?

A1: Use a SIIKE TPU based Matte Effect Masterbatch to stabilize the surface microstructure and reduce friction during extrusion.

Q2: Why do TPU matte surfaces bloom or show white specks?

A2: Blooming often occurs due to migration of incompatible additives or oils. A well-formulated High-Performance Matt Flatting Agent ensures encapsulation and stability.

Q3: How to enhance scratch resistance without losing matte finish?

A3: Introduce wear-resistant micro-particles within a silicone-modified masterbatch to balance friction reduction and matte aesthetics.

Q4: What is the recommended dosage for SILIKE Matt Effect Masterbatch?

A4: Typically 1–10 wt% depending on TPU grade and desired matte effect. Pre-compounding ensures uniform distribution.

Q5: Can this Anti-blocking Matt Effect masterbatch be used in high-speed extrusion for cable jackets?

A5: Yes. It is designed to maintain surface consistency and avoid defects even under high shear and thermal stress.

Optimizing TPU compound formulations for matte effect, wear resistance, and long-term surface integrity is no longer a compromise. With SILIKE Matt Effect Masterbatch, R&D engineers and cable manufacturers can achieve:

√ Stable matte surface from production to end-use

√ Enhanced scratch and wear resistance

√ Long-term prevention of blooming and additive precipitation

Interested in enhancing your TPU cable formulations? Contact SILIKE Matt Effect Masterbatch Manufacturer to request a free sample or technical consultation and experience high-performance matte TPU surfaces firsthand, as well as TPU surface modification techniques for cable applications.

Please Reach Amy Wang at amy.wang@silike.cn or visit www.siliketech.com for durable matte TPU compound formulation solution

Post time: Nov-26-2025