How is a Matte Finish Achieved in TPU Films?

A matte finish on TPU (thermoplastic polyurethane) films is born from the innovative fusion of material formulation and manufacturing processes, transforming the surface texture to reduce gloss. This process achieves a non-reflective, diffused appearance, showcasing the beauty of purposeful design and creativity. Here’s how matte TPU film is typically created, and an innovative matte technology:

1. Material Formulation:

Additives: By incorporating specialized additives such as silica and calcium carbonate or other matting agents into the TPU resin, manufacturers can effectively disrupt the surface smoothness. This scattering of light significantly reduces gloss and enhances the matte quality of the film.

Polymer Blends: Adjusting the TPU formulation with specific polymers or fillers can naturally lower the material’s reflectivity during processing, promoting a more matte finish.

SILIKE Matt Effect Masterbatch 3135 is an innovative matting additive designed specifically for TPU films. It is formulated with Polyester TPU as the carrier, offering numerous benefits:

1) Enhanced Matte Appearance: This High Value Functional Matte Additive delivers a consistent and smooth matte finish, also maintains TPU’s flexibility, durability, and other functional properties, making it ideal for applications like protective films, wire, cable, automotive interiors, or consumer electronics.

2) Anti-Blocking Properties: By minimizing surface tack, this Eco-friendly TPU Matt Effect Masterbatch effectively prevents blocking, facilitating improved handling and processing.

3)Eco-Friendly and User-Friendly: The incorporation of SILIKE Matte effect Masterbatch 3135 into the manufacturing process is straightforward, requiring no granulation. This reliable solution reduces the risk of precipitation, ensuring efficiency.

Different Matte Agents for TPU Films: Testing and Performance Comparison

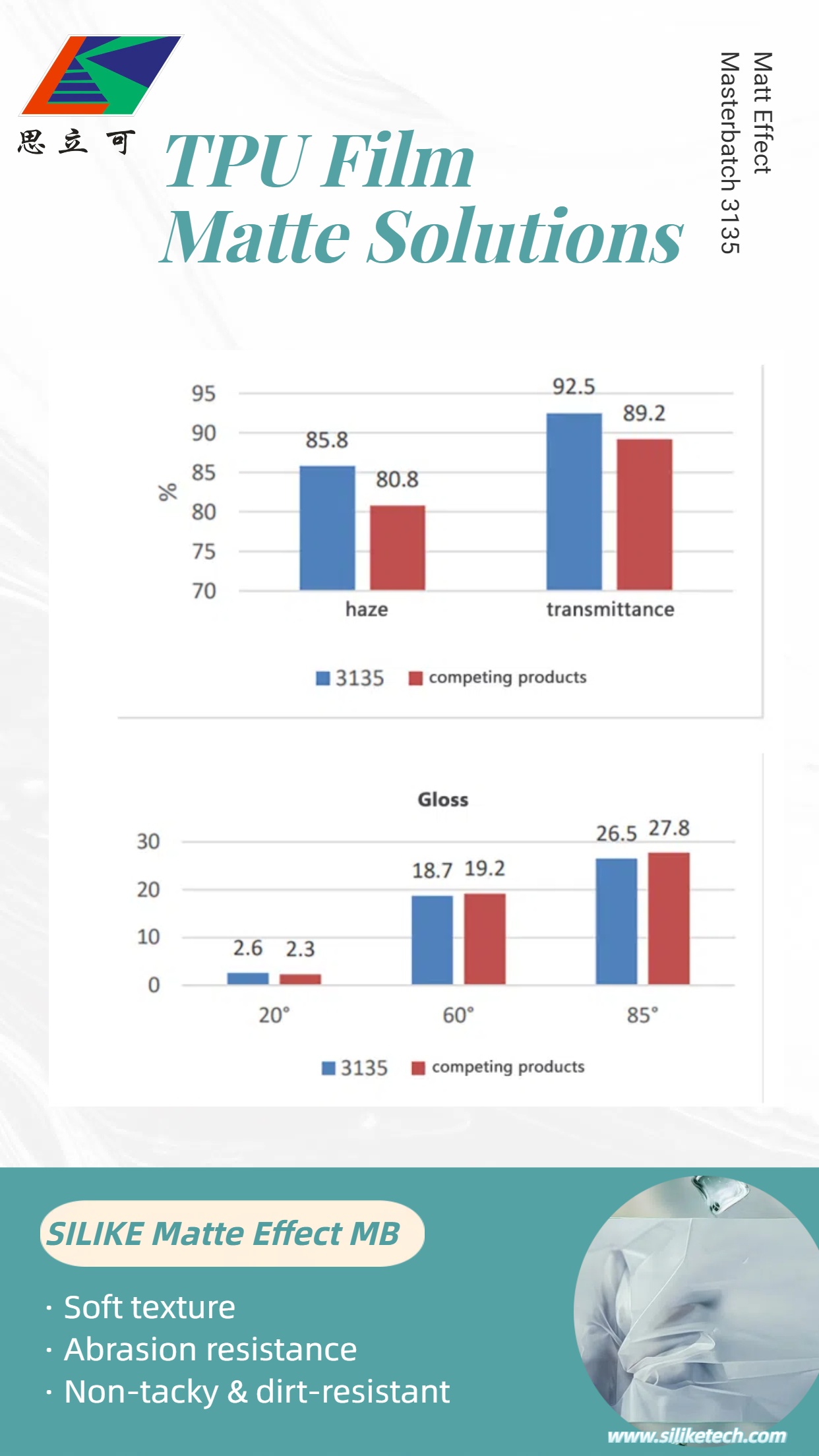

To validate its effectiveness, Mix 10% of SILIKE Matt Effect Masterbatch 3135 with polyester TPU evenly, then directly cast to obtain a film with a thickness of 10 microns. Test the haze, light transmittance, and gloss, and compare with a competing matte TPU product. The resulting data highlighted its outstanding performance characteristics:

2. Surface Texturing Techniques During Manufacturing:

Extrusion with Textured Rollers: The extrusion process offers a key opportunity to create a matte surface. By melting TPU and passing it through rollers with a textured surface—achieved through methods like sandblasting, etching, or micro-patterning—manufacturers can imprint a micro-rough texture that diffuses light and enhances the matte appearance.

Calendering: This process involves passing the TPU film through a series of rollers. One or more of these rollers may have a matte or frosted finish, effectively embossing the desired texture onto the film’s surface.

Cooling: Following the texturing process, cooling the film solidifies the matte pattern, ensuring that the surface structure is maintained.

3. Post-Processing Techniques:

Mechanical Abrasion: Lightly sanding, blasting (with sand or beads), or brushing the TPU film creates micro-scratches that contribute to reducing gloss levels.

Chemical Etching: By applying a mild chemical treatment, manufacturers can achieve a textured surface at a microscopic level, resulting in a matte effect that preserves the integrity of the film.

Coating: Applying a thin layer of matte coating (such as a polyurethane-based solution with matting agents) via methods like spraying, roll-coating, or dipping can bond effectively with the TPU film, enhancing its matte finish.

4. Effective Process Control:

Temperature and Pressure Management: Ensuring precise control over temperature and pressure during extrusion or calendering is crucial. This control helps consistently apply the desired texture without compromising the TPU’s properties.

Speed Optimization: The speed of the film passing through rollers or processing equipment directly influences the uniformity and depth of the matte finish, making speed management critical for quality outcomes.

Struggling with TPU Film Soft Texture, Gloss, or Haze? Want to Achieve Premium Matte Finishes for Your TPU Film Production?

Contact SILIKE, the professional polymer additives manufacturer for matte finishes, Welcome to learn more about our innovative Matt Effect Masterbatch solutions. Request a sample of SILIKE’s anti-blocking matte effect additives!

Tel: +86-28-83625089,Email: amy.wang@silike.cn

Post time: Jun-06-2025