Why High-Filler LSZH Extrusion Often Fails?

LSZH (Low Smoke Zero Halogen) cables are widely used in construction, transportation, and telecom applications for their low smoke emission and halogen-free safety performance.

However, when ATH or MDH filler loadings increase in LLDPE or EVA systems, extrusion instability is no longer a formulation issue alone—it becomes a melt–metal interface problem.

In high-filler LSZH compounds, processors commonly encounter:

• Unstable line speed and uneven melt flow

• Surface defects such as scratches, roughness, and die drool

• Reduced flame retardancy and long-term performance when conventional waxes or stearates are used

Especially, when we spoke with wire and cable compound manufacturers in China, Some Cable Engineers mentioned, “We often face Unstable line speed, die build-up, and surface scratches when extruding high-filler LSZH compounds.” Typically, they rely on conventional processing aids to address these issues. We introduced SILIKE UHMW Silicone Additives as an alternative processing aid solution to enhance the processing properties of plastic materials while improving the final surface quality of wire and cable components.

How SILIKE UHMW Silicone Additives Improve LSZH Extrusion?

1. Enhanced Extrusion Stability and Higher Line Speed

SILIKE LYSI series silicone additives form a dynamic lubricating layer between the polymer melt and metal surfaces inside the extruder and die. This reduces die pressure, minimizes melt adhesion, and effectively prevents die build-up.

Even in high-filler LSZH formulations, processors can achieve faster and more stable extrusion, reducing scrap rates and improving overall productivity.

“After using LYSI silicone additives, especially SC920, our extrusion line speed increased by 10–20%, and surface defects were significantly reduced.”

— Production Manager Wang

2. Improved Surface Quality and Cable Appearance

LYSI-300P Resin-Free Silicone Processing Aid provides long-lasting surface lubrication without migration. It enhances scratch and abrasion resistance, resulting in smoother, more uniform LSZH cable jackets with improved visual appearance.

Many wire and cable compound manufacturers value LYSI-300P for its ability to improve both processing efficiency and finished surface quality without negatively affecting downstream performance.

3. Better Mechanical Properties and Flame Retardancy

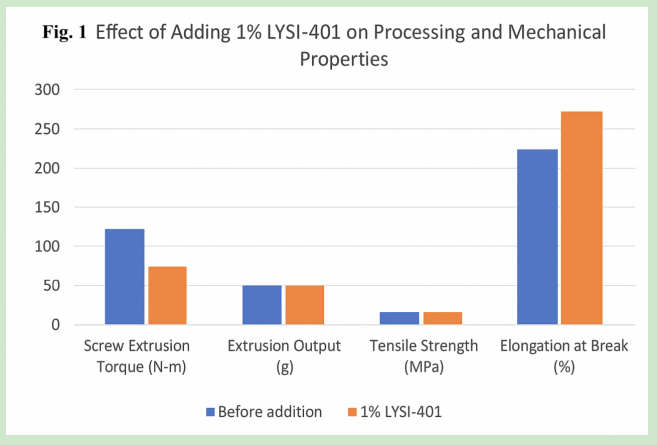

Unlike low molecular weight waxes, SILIKE silicone masterbatch LYSI-401 provides effective lubrication while promoting more uniform dispersion of ATH and MDH fillers. As a result, extruded wires and cables benefit from:

• Faster and more stable extrusion in high ATH/MDH systems

• The extruded wire and cable surface will be smoother, meanwhile, Lower coefficient of friction (CoF), better abrasion resistance, and scratch resistance.

“With SILIKE silicone masterbatch, the surface quality of our LSZH cables has significantly improved.”

— Quality Engineer Chen, China

Key Benefits of SILIKE Silicone-Based Additives and Surface Modifiers for Wire & Cable Compounds

√ Solve processing issues: improve mold filling and release, optimize extrusion parameters, and reduce die drool

√ Enhance surface properties: lower CoF, improved scratch and abrasion resistance, better surface slip, and hand feel

√ Faster dispersion of flame retardants (ATH/MDH)

√ Synergistic flame retardant effect without migration

√ SILIKE silicone additives simultaneously improve processing efficiency and the surface quality of finished wire and cable products.

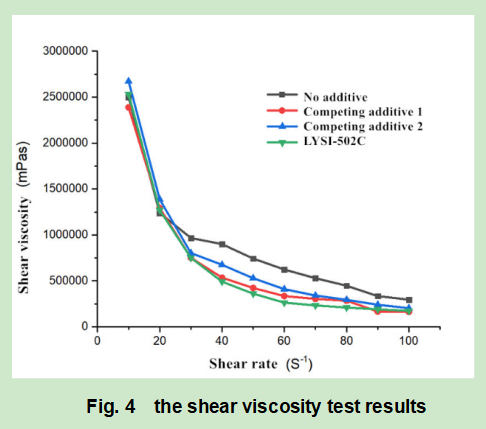

Typical Test data of SILIKE LYSI Series Silicone Masterbatch (Siloxane Masterbatch) in High-Filler LSZH Flame-Retardant Cable Compounds

FAQ – LSZH Cable Processing Methods & Solutions for Excellent Aesthetic Surface Finish

Q1: How can die build-up be reduced while maintaining stable line speed?

Dynamic internal lubrication from UHMW silicone additives reduces die pressure and ensures uniform melt flow.

Q2: Which SILIKE additive is suitable for high-filler LSZH or HFFR compounds?

The LYSI series (silicone masterbatch, silicone powder, or resin-free UHMW silicone-based processing additives) provides optimized internal and external lubrication for high-filler systems.

Q3: Can SILIKE silicon-based additives improve high-ATH-filled compounds?

Yes. They improve filler dispersion, reduce extrusion pressure, and enhance surface quality.

Q4: Will silicone additives affect flame-retardant performance?

No. Non-migrating silicone additives enable faster dispersion of ATH/MDH and provide a synergistic flame-retardant effect.

Q5: Are LYSI SILIKE silicone additives compatible with other cable materials?

Yes. SILIKE LYSI series silicone processing additives are compatible with HFFR, TPU, TPE, PVC, XLPE, and related wire and cable compounds, as well as other polymer systems.

Get Samples and Technical Support

Contact SILIKE to evaluate LYSI silicone additives in your LSZH cable formulations. Our technical team provides application support to optimize extrusion efficiency and surface quality performance.

SILIKE isn’t here just to sell silicone additives.

Chengdu Silike Technology Co., Ltd. (SILIKE) is a leading Chinese manufacturer specializing in silicone-based plastic additives and thermoplastic elastomers for the plastics and rubber industries. With over 20 years of dedicated research into integrating silicone with polymers, we are recognized as both an innovator and a trusted partner for high-performance additive solutions.

We’re here to help wire and cable manufacturers run faster, cleaner, and more consistently—especially in high-filler, high-speed extrusion environments.

If you’re looking for UHMW silicone masterbatches, resin-free silicone processing aids, or high-performance siloxane additives that truly solve processing and surface challenges, start here:www.siliketech.com

Typical Applications of SILIKE Silicone Processing Additives and Surface Modifiers for Wire and Cable compounds:

Silane crosslinked XLPE cables

….

Post time: Jan-08-2026