Struggling with inconsistent flame retardant dispersion in your polymer products? Poor distribution not only weakens fire safety performance but also degrades mechanical properties and drives up costs. What if you could solve these issues with the right dispersants? In this article, we’ll explore how Latest dispersant technologies can transform your flame retardant systems—ensuring uniform dispersion, enhancing fire resistance, and streamlining processing efficiency for superior results.

Why Flame Retardant Dispersion Matters for Polymer Manufacturers?

Problem 1: Inconsistent Flame Retardant Dispersion Leads to Safety Concerns

If your flame retardant additives aren’t dispersed evenly, you might face safety issues, such as:

Weakened Fire Resistance: Lower Limiting Oxygen Index (LOI) and unstable UL94 ratings.

Surface Quality Issues: Rough textures and low gloss affect aesthetic appeal and durability.

Reduced Mechanical Strength: Increased brittleness and flow issues in the final product.

Higher Production Costs: Rework, wasted materials, and longer processing times.

Problem 2: Performance Limitations with Traditional Flame Retardant Systems

Traditional methods of flame retardant dispersion often struggle with particle agglomeration, leading to inconsistent performance. This can impact your ability to meet regulatory requirements and hinder the final product’s performance in real-world applications.

Latest Flame Retardant Solution: SILIMER 6600 Hyperdispersant Optimize FR Dispersion in Polymers

SILIKE SILIMER 6600 is an innovative silicone-based polymer additive, when used as a dispersant, that addresses the common dispersion challenges faced by polymer manufacturers. Its unique formulation of a triblock copolymer—combining polysiloxane, polar groups, and long carbon chain groups—delivers exceptional results. It has a wide range of applications, including flame retardant dispersion, pigment dispersion, and filler dispersion.

How Does Silicone Hyperdispersant of SILIMER 6600 Work?

1. Improved Flame Retardant Dispersion: Polar groups in the hyperdispersant bond with flame retardants, ensuring a stable, uniform dispersion throughout the polymer matrix.

2. Prevents Re-Agglomeration: Polysiloxane segments maintain a stable dispersion even under mechanical shear, ensuring that the flame retardant remains evenly distributed.

3. Increased Compatibility with Base Materials: The long carbon chains ensure compatibility with polyolefin systems, preventing migration or exudation of flame retardants during processing.

Key Advantages of Dispersant technology SILIMER 6600 in Flame Retardant Applications:

1. Improves flame retardant dispersion in the base material, enhancing flame retardant performance.

2. Enhances mechanical properties by ensuring uniform dispersion of flame retardants.

3. Prevents re-agglomeration of flame retardant particles, maintaining stable dispersion.

4. Excellent compatibility with polyolefin systems, minimizing migration or exudation.

5. Acts as a processing aid, improving lubrication and production efficiency.

Performance Evaluation of dispersant SILIMER 6600 in Flame Retardant Systems

1. Experimental

Phosphorus-Nitrogen Intumescent Flame Retardant

Preparation Method: Flame retardant treated with dispersant → Compounded with resin → Injection molded into test specimens → Performance testing

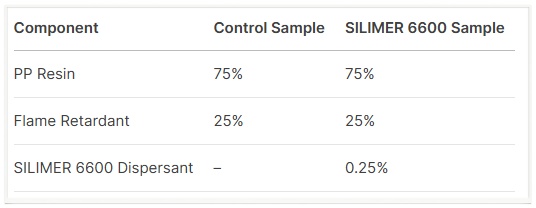

2. Formulation

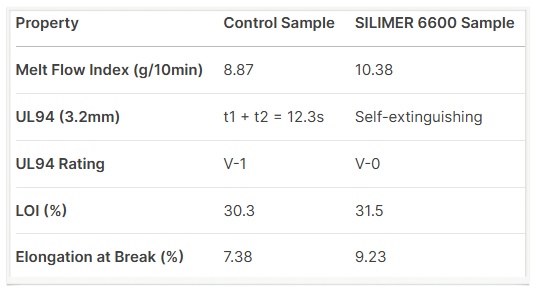

3. Test Results

4. Conclusion

Improved Flame Retardancy: The treated sample achieved UL94 V-0 rating (vs. V-1 for control) and faster self-extinguishing behavior.

Enhanced Processing: Higher melt flow index indicates better processability.

Mechanical Property Retention: Increased elongation at break confirms better dispersion without sacrificing material strength.

If you’re facing flame retardant dispersion issues, low UL94 ratings, or processing challenges, contact SILIKE to get your multi-functional dispersant. Not only does it offer the SILIMER 6600 solution for flame retardant masterbatch, but it also provides advanced dispersant technology optimized for pigments and fillers.

(Learn More: www.siliketech.com | Email: amy.wang@silike.cn)

Post time: May-28-2025