Why the Need for PTFE (PFAS) Alternatives?

In today’s rapidly evolving world of sustainable materials, industries are facing increasing pressure to adopt environmentally friendly solutions. Engineering plastics, known for their durability and versatility, are no exception. For years, PTFE (Polytetrafluoroethylene) has been go-to materials for engineering plastics, prized for their chemical resistance, low friction, and high thermal stability.

However, PTFE belongs to the PFAS (Per- and Polyfluoroalkyl Substances) family, which has raised important environmental concerns due to its persistence and resistance to degradation. Often called “forever chemicals,” PFAS have the potential to accumulate in ecosystems and pose risks to human health, including issues related to the immune and endocrine systems, liver function, and even more serious conditions like cancer.

In response to these challenges, many countries are tightening regulations around PFAS substances. For instance:

The European Union’s REACH regulation has identified PFAS as a “substance of very high concern,” leading to strict restrictions on its use.

The U.S. Environmental Protection Agency (EPA) has initiated monitoring and phase-out plans for PFAS chemicals.

So, how can engineering plastics maintain their high performance while minimizing environmental impact? PFAS-Free and PTFE-Free solutions provide the ideal answer, delivering the same high-performance benefits without the environmental and health risks.

What is the alternative to PTFE? High-Performance, PFAS-Free Additives for Engineering Plastics

Introducing SILIKE Fluorine-Free Wear-Resistant Additives and PTFE Alternatives

Key Advantages of PTFE Replacement Additive SILIKE LYSI-701 for Engineering Plastics:

1. Fluorine-Free Composition: A fully PFAS-free formulation that aligns with rigorous global environmental standards.

2. Enhanced Wear Resistance: Even a small amount of this additive can significantly improve the durability and lifespan of engineering plastics when compared to PTFE.

3. Superior Lubrication: It effectively reduces friction and enhances processing efficiency, driving better performance.

4. Wide Applicability: Suitable for diverse materials such as PA6, PA66, PC, ABS, POM, PBT, PPS, and many more engineering plastics.

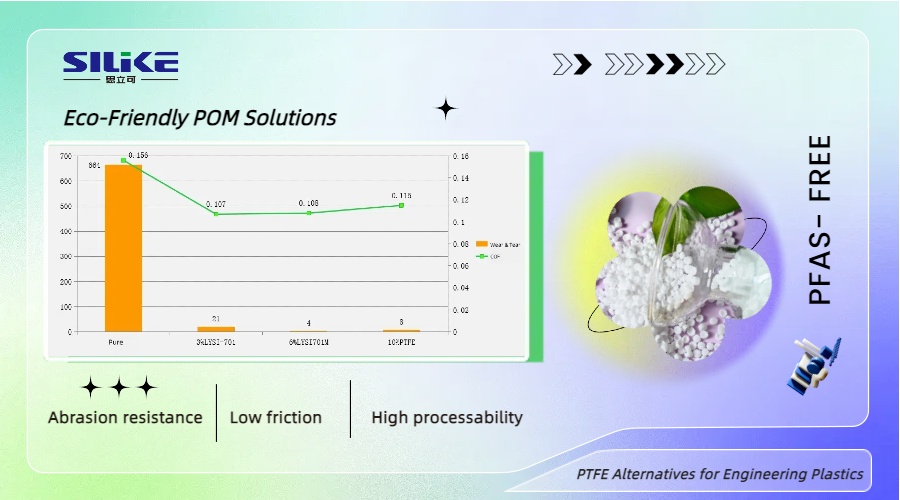

Laboratory tests verify: 3 wt% LYSI-701 in POM exhibits superior wear resistance and a lower coefficient of friction (COF) compared to 10 wt% PTFE under identical test conditions.

New Guide to Avoiding PTFE and PFAS (Forever Chemicals) in Engineering Plastics Products

For researchers working in the field of engineering plastics, are you navigating the challenges posed by increasing regulatory scrutiny on PFAS in engineering plastics? Are you seeking high-performance additives, anti-abrasion agents, or modifiers of engineering plastics, or a replacement for PTFE that prioritizes environmental health?

The advent of novel PFAS-free materials opens up a world of possibilities. These alternatives have the potential not only to match the performance of PTFE but also to mitigate its environmental footprint.

Embracing a stance that is both safety-conscious and environmentally friendly, we guide our clients through the complexities of this evolving market. SILIKE has pioneered several PFAS-free solutions tailored for engineering plastics applications. We stand as your ally in the quest for sustainable alternatives to PTFE and in the abandonment of potentially hazardous PFAS substances.

SILIKE invite you to contact us to explore these innovative Effective Tribology Modifiers and PTFE Alternatives options and how they can benefit your projects.

Reach out to SILIKE at amy.wang@silike.cn or visit www.siliketech.com to discover how our PTFE alternative solutions can support your applications while helping you meet evolving regulatory standards.

Post time: Apr-24-2025