How to improve the abrasion resistance of shoe soles?

As a necessity in people’s daily life, shoes play a role in protecting the feet from injury. Improving the abrasion resistance of shoe soles and extending the service life of shoes has always been a major demand for shoes. For this reason, SILIKE has developed a series of Anti-abrasion masterbatch for shoe soles.

As an elastomer composite material, shoe soles will produce friction with the ground in the process of use, which affects the abrasion, and improving the abrasion resistance of shoe soles is of great significance for the safety, service life and energy saving of shoe soles. Higher resilience, high strength, light weight, abrasion resistance, lower compression deformation of the sole material will also be the future development trend.

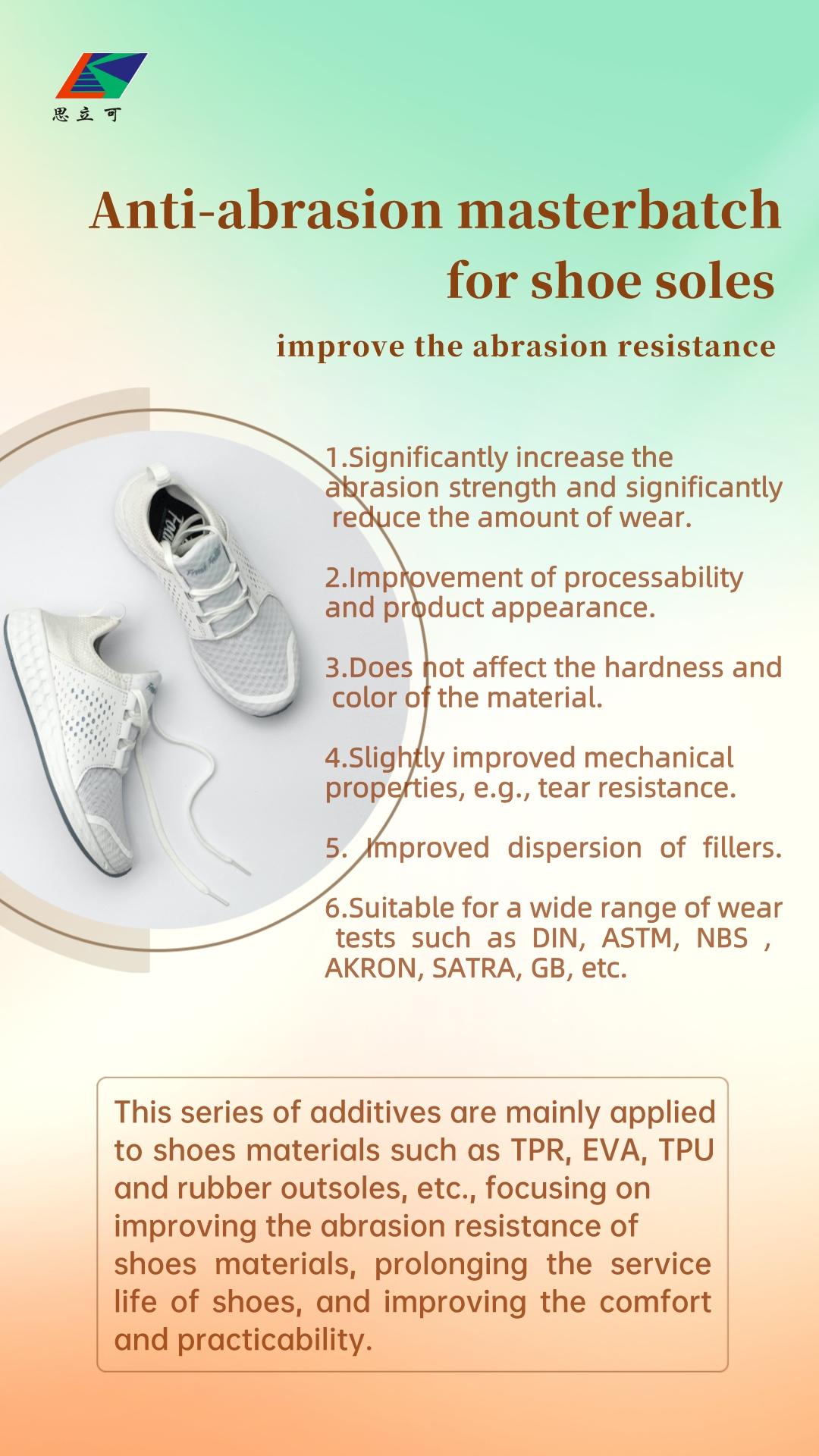

Anti-abrasion masterbatch for shoe soles as a branch of the silicone series of additives, in addition to the general characteristics of silicone additives, focusing on amplifying its wear-resistant properties, greatly improving the wear resistance of shoe materials. This series of additives are mainly applied to shoes materials such as TPR, EVA, TPU and rubber outsoles, etc., focusing on improving the abrasion resistance of shoes materials, prolonging the service life of shoes, and improving the comfort and practicability.

Compared with traditional footwear wear-resistant agents, The series of SILIKE Anti-abrasion masterbatch has the following features:

1.Significantly increase the abrasion strength and significantly reduce the amount of wear.

2.Improvement of processability and product appearance.

3.Does not affect the hardness and color of the material.

4.Slightly improved mechanical properties, e.g., tear resistance.

5. Improved dispersion of fillers.

6.Suitable for a wide range of wear tests such as DIN,ASTM,NBS,AKRON,SATRA,GB,etc.

Post time: Aug-04-2023