Footwear manufacturers are under increasing pressure to build shoes that last — not just look good on day one. Daily friction, harsh weather, and demanding environments can quickly wear out midsoles and outsoles, causing discomfort, safety risks, and unexpected product returns.

Today, abrasion resistance is no longer just a material feature — it’s a business advantage. Poor durability damages brand reputation and drives up production costs, while customers demand longer-lasting comfort and performance.

If you’re working with EVA, TPR, TPU, or color rubber compounds, there is now a proven way to strengthen shoe soles without changing hardness or processing parameters.

Scroll down, you’ll discover how wear-resistant solutions improve durability— all while keeping manufacturing efficient.

What Are the Common Shoe Sole Materials and Their Challenges?

EVA (Ethylene Vinyl Acetate)

Lightweight and cushioned, EVA provides excellent shock absorption but may lack long-term abrasion resistance under heavy use.

TPR (Thermoplastic Rubber)

Combines flexibility, slip resistance, and durability, commonly used in casual shoes and children’s footwear. However, wear can be uneven over time.

TPU (Thermoplastic Polyurethane)

Offers high elasticity and abrasion resistance, ideal for sports and outdoor footwear, maintaining performance in harsh conditions.

PU (Polyurethane)

Durable and lightweight, PU provides cushioning and abrasion resistance, widely used in midsoles and comfort-focused shoes.

Rubber (Natural and Synthetic)

Natural rubber delivers elasticity and resilience; synthetic rubbers (SBR, NBR) improve abrasion resistance and weather durability. Processing and uniform wear remain challenges.

Industry Pain Point: Traditional additives often fail to maintain consistent hardness, surface quality, or color, leading to premature wear and reduced customer satisfaction.

How Do Additives SolveThese Problems?

The Solution: Anti-abrasion additives in Shoe Sole Materials

SILIKE Anti-Abrasion Silicone Masterbatch

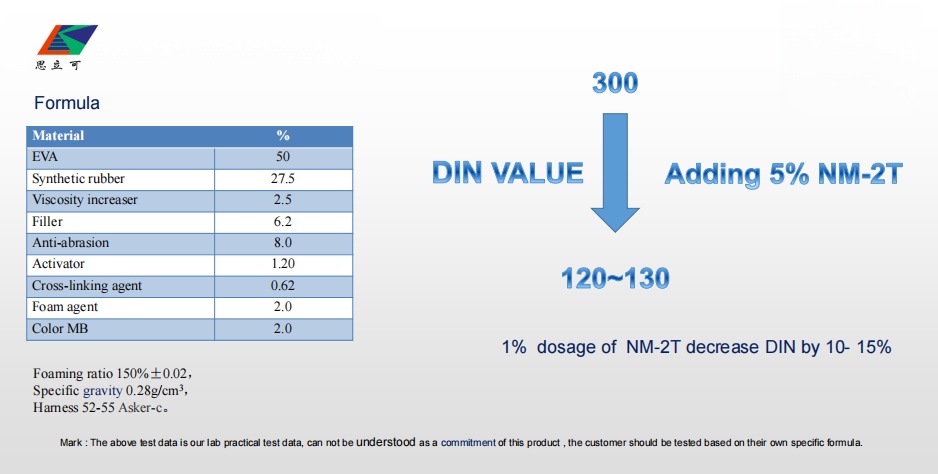

SILIKE Anti-Abrasion Masterbatch is specifically engineered to enhance the performance of TPR, EVA, TPU, and color rubber soles. Part of SILIKE’s series of silicone additives, the NM series wear-resistant agent focuses on maximizing abrasion resistance while maintaining the inherent properties of the base material.

Key Benefits of Anti-abrasion Masterbatch for the shoes’ outsole

• Outstanding abrasion resistance at cost-effective addition levels

• Improved filler dispersion for uniform material properties

• Maintains hardness and original surface feel

• Enhanced color consistency

• Uniform abrasion resistance on inner and outer surfaces

• Improved processing performance and finished appearance

How SILIKE Anti-abrasion masterbatches NM series Works?

The SILIKE Anti-abrasion masterbatches NM series optimizes filler dispersion and surface properties, delivering soles that are durable, comfortable, and visually appealing without changing hardness or flexibility.

Real-World Performance and Customer Feedback on Anti-Abrasion Additives in Shoe Sole Compounds

In EVA, TPR, TPU, and rubber soles, SILIKE’s abrasion resistance agent has demonstrated:

• Reduced wear and extended shoe lifespan

• Enhanced comfort without sacrificing flexibility

• Simplified manufacturing with fewer defects

EVA shoe sole Customer Testimonial:

“After incorporating SILIKE Anti-Wear Agent NM-2T into our EVA soles, the abrasion resistance improved significantly without affecting softness. Production consistency also improved.” – R&D Manager, Footwear Brand

Why Brands and R&D Teams Should Consider SILIKE abrasion resistance agent?

• Deliver longer-lasting, high-quality shoes

• Improve consumer satisfaction and brand reputation

• Reduce production defects and costs

FAQ (Helpful Content for footwear Engineers & shoe sole Decision-Makers)

Q1: How to improve the EVA shoe sole abrasion resistance?

A: Incorporating SILIKE Anti-Abrasion Silicone Masterbatch NM-2T improves EVA sole abrasion resistance without changing hardness or flexibility.

Q2: Will SILIKE NM 6T anti-wear agent affect TPU or TPR shoe sole performance?

A: No. It enhances abrasion resistance and processing while maintaining original flexibility, hardness, and surface quality.

Q3: Which shoe sole materials are compatible with SILIKE NM series Anti-abrasion silicone Masterbatch?

A: EVA, TPR, TPU, PU, and color rubber soles, delivering uniform durability and improved comfort.

Elevate your shoe materials with SILIKE anti-abrasion additives to produce soles that last longer, perform better, and maintain premium aesthetics.

Request a sample or technical consultation to explore the best solution for your EVA, TPR, TPU, PU, or rubber soles. Contact SILIKE, your abrasion resistance agent manufacturer!

TEL: +86 – 28 – 83625089

Email: amy.wang@silike.cn

Website: www.siliketech.com

Post time: Dec-05-2025