Hyperdispersants Are Reshaping Flame Retardant Masterbatch Performance

Poor flame-retardant performance in masterbatch and compound formulations is increasingly caused by inefficient dispersion rather than insufficient additive loading. Improving dispersion efficiency through hyperdispersants enables higher UL94 ratings, increased LOI values, and more stable processing — without sacrificing mechanical properties.

From High Loading to High Efficiency: A New Direction for Flame Retardant Compounds

As global fire safety standards continue to tighten across automotive, electronics, construction, and consumer goods industries, flame-retardant masterbatch and compound manufacturers are facing increasing pressure. Achieving higher UL94 ratings and LOI values is no longer enough — today’s formulations must also maintain mechanical performance, surface quality, and processing stability.

In this evolving landscape, a critical issue has become increasingly clear: many flame-retardant systems fail not because of insufficient additive content, but because of poor dispersion efficiency.

Why Flame Retardant Masterbatches Still Fail — Even with High Additive Loading

Why does increasing flame-retardant loading often fail to achieve UL94 V0?

Because agglomeration and uneven distribution reduce the effective working area of flame retardants, creating localized weak points during combustion.

In practical production, formulators often encounter the following challenges:

• UL94 ratings remain at V1 or V2 despite high flame-retardant loading

• LOI values plateau and become difficult to improve

• Flame-retardant fillers agglomerate and disperse unevenly

• Melt flow deteriorates, narrowing the processing window

• Mechanical properties and surface appearance are compromised

These issues point to a common root cause: flame retardants are not being fully and effectively utilized within the polymer matrix.

Dispersion: The Hidden Variable Behind Flame Retardant Efficiency

What determines real flame-retardant efficiency in polymer compounds?

Uniform dispersion across the entire polymer matrix — not just the total amount of flame retardant added.

Flame retardants can only perform as intended when they are uniformly distributed throughout the polymer. Localized agglomeration creates weak points where flame resistance fails, while excessive loading negatively impacts processing and end-use performance.

As a result, the industry is shifting its focus from simply increasing flame retardant dosage to optimizing dispersion efficiency — enabling higher flame retardant performance at more controlled additive levels.

This shift has brought hyperdispersants into the spotlight as a key formulation tool for next-generation flame-retardant masterbatches.

Hyperdispersants: Enabling High-Performance Flame Retardant Systems

Unlike conventional processing aids, hyperdispersants are designed to significantly reduce interfacial energy between flame retardants and the polymer matrix. This promotes:

• Uniform dispersion of organic and inorganic flame retardants

• Improved interaction between fillers and polymer chains

• Enhanced flame-retardant efficiency across the entire compound

By addressing dispersion at a fundamental level, hyperdispersants allow formulators to unlock the full potential of existing flame retardant systems.

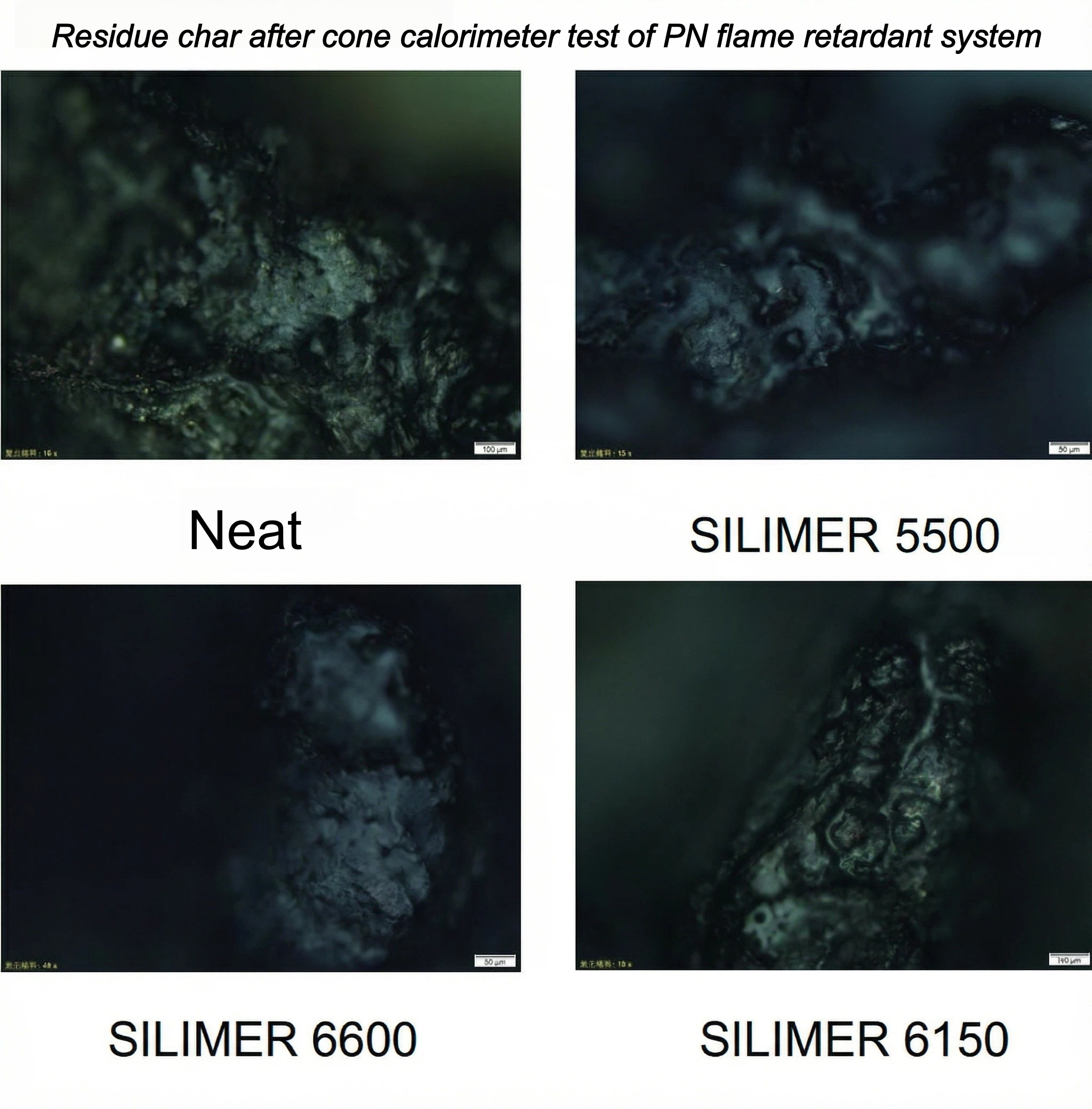

SILIKE Silicone Hyperdispersants: Designed for Boosting the Performance of Flame Retardant Masterbatches and Compounds

Developed to meet the demanding requirements of modern flame retardant formulations, SILIKE SILIMER Silicone hyperdispersants are modified silicone wax dispersants engineered to improve dispersion efficiency in flame retardant masterbatch and compound applications.

Recommended Applications:

√ Phosphorus–nitrogen flame retardant systems

√ Antimony–bromine synergistic flame retardant systems

√ High-loading inorganic flame retardant formulations

Applicable Polymer Systems:

PE, PP, PS, ABS, PVC, TPE, TPU, and other thermoplastics

Performance Benefits Observed in Flame Retardant Compounds

When incorporated into flame-retardant formulations, Modified Silicone Wax SILIMER Hyperdispersants have demonstrated the ability to:

• Significantly improve flame retardant dispersion

• Increase LOI values

• Upgrade UL94 ratings from V2 or V1 to V0

• Improve melt flow and processing stability

• Enhance surface smoothness and reduce the coefficient of friction

• Maintain mechanical properties without negative impact

These benefits support a more balanced formulation approach — achieving flame retardancy without sacrificing manufacturability or product quality.

From Additive Selection to System Optimization of Flame Retardant Masterbatches

The evolution of flame retardant materials is no longer centered on selecting stronger flame retardants alone. Instead, success increasingly depends on how effectively those flame retardants are dispersed and utilized within the polymer matrix.

SILIKE Hyperdispersants such as SILIMER 6150 represent a strategic shift toward system-level optimization, helping formulators meet higher safety standards while maintaining performance, efficiency, and cost control.

Looking Ahead: Smarter Flame Retardant Formulations

What This Means for Flame Retardant Formulators

• Dispersion efficiency is becoming a decisive performance variable

• Hyperdispersants allow higher flame retardant efficiency at controlled additive levels

• System-level optimization is replacing additive-heavy formulation strategies

Interested in improving flame-retardant and compound dispersion in your formulations?

SILIKE’s technical team works closely with compounders and masterbatch producers to evaluate formulation challenges and develop optimized flame retardant solutions.

Contact SILIKE to discuss your flame-retardant system and dispersion challenges.

Post time: Jan-28-2026