Why Fire Safety Remains a Critical Issue in Plastics and Fibers

In modern plastic and fiber manufacturing, fire safety is more than a compliance requirement—it’s a direct factor affecting product reliability and brand reputation.

Yet traditional flame-retardant approaches often create new problems: uneven dispersion, difficult processing, higher usage levels, and negative impacts on material strength.

Flame retardant masterbatches have quickly become a preferred alternative. Their concentrated, pre-dispersed design improves consistency, maintains mechanical properties, and supports smoother production—helping manufacturers stay competitive in demanding markets.

What Exactly Are Flame Retardant Masterbatches?

Flame retardant masterbatches are high-efficiency additive concentrates engineered to deliver controlled, uniform flame retardancy in polymers. Compared with loose powders, they offer:

Core Benefits of FR Masterbatches

♦ Uniform dispersion for stable flame-retardant performance

♦ Lower dosage requirements, reducing material cost

♦ Better processing flow and easier handling

♦ Minimal impact on mechanical properties

♦ Cleaner, safer working environments with less dust

These advantages make them ideal for applications in textiles, construction materials, automotive interiors, electronics, and other safety-critical sectors.

Types and Applications of Flame Retardant Masterbatches

1. Fiber Flame Retardant Masterbatches

1.1 Polypropylene (PP) Fiber Masterbatches

Applications: Curtains, sofas, carpets, mining belts, air duct fabrics

Features: High-concentration flame retardants blended with synergistic additives and spun into fibers for long-term fire resistance

1.2 Polyester (PET) Fiber Masterbatches

Applications: Industrial textiles, architectural fabrics, automotive interiors, protective clothing

Features: Permanent flame retardancy suitable for apparel and industrial uses

2. Plastic Flame Retardant Masterbatches

2.1 ABS Masterbatches

Problem: ABS is highly flammable (LOI 18.3–20%)

Solution: Masterbatch technology enables uniform dispersion of FR additives, improving fire safety without sacrificing mechanical performance

2.2 High-Impact Polystyrene (PS-HI) Masterbatches

Applications: Electrical appliances, automotive parts, household equipment

Features: Expanded application scenarios with mature multi-functional masterbatches (color + FR)

2.3 Polyamide (PA6) Masterbatches

Applications: Engineering plastics, electronics, electrical components

Features: FR modification ensures safe usage in high-performance applications

2.4 Polyoxymethylene (POM) Masterbatches

Challenge: Difficult-to-fire polymers

Solution: Precision masterbatch technology guarantees FR performance and maintains mechanical strength

Applications: Automotive, electronics, precision machinery, building materials

2.5 Polyolefin Masterbatches

Applications: Pipes, sheets, cables, electrical parts, decorative materials

Advantages: Easy to use, cost-effective, excellent processing performance

SILIKE SILIMER 6600 is an innovative silicone-based polymer additive, when used as a dispersant, that addresses the common dispersion challenges faced by polymer manufacturers. Its unique formulation of a triblock copolymer—combining polysiloxane, polar groups, and long carbon chain groups—delivers exceptional results. It has a wide range of applications, including flame retardant dispersion, pigment dispersion, and filler dispersion.

SILIKE SILIMER 6600 is an innovative silicone-based polymer additive, when used as a dispersant, that addresses the common dispersion challenges faced by polymer manufacturers. Its unique formulation of a triblock copolymer—combining polysiloxane, polar groups, and long carbon chain groups—delivers exceptional results. It has a wide range of applications, including flame retardant dispersion, pigment dispersion, and filler dispersion.

How SILIMER 6600 Dispersant Improves the Properties of Flame Retardant Masterbatches

1. Improved Flame Retardant Dispersion: Polar groups in the hyperdispersant bond with flame retardants, ensuring a stable, uniform dispersion throughout the polymer matrix.

2. Prevents Re-Agglomeration: Polysiloxane segments maintain a stable dispersion even under mechanical shear, ensuring that the flame retardant remains evenly distributed.

3. Increased Compatibility with Base Materials: The long carbon chains ensure compatibility with polyolefin systems, preventing migration or exudation of flame retardants during processing.

Key Advantages of dispersing agent SILIMER 6600 for Flame Retardant Systems

♦ Enhanced dispersion → higher flame-retardant efficiency

♦ Maintains mechanical properties → better tensile and elongation performance

♦ Prevents FR particle clumping → consistent stability

♦ Excellent polyolefin affinity → reduced migration

♦ Lubrication effect → smoother extrusion and improved throughput

Application Study in flame retardant Phosphorus–Nitrogen FR System

1. Preparation Approach

Flame Retardant: Phosphorus–Nitrogen flame retardant

Preparation Method: The flame retardant was treated with a dispersant, then directly compounded with the resin to form pellets → Injection molding to prepare test specimens → Performance testing

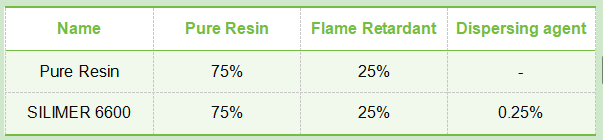

2. Experimental Formulation

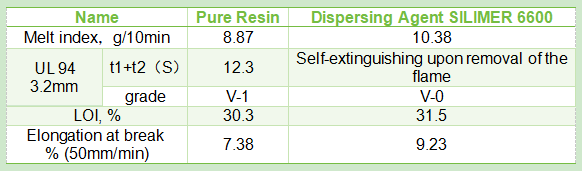

3. Test Data

4. Test Conclusion

Adding SILIMER 6600 significantly improved the distribution of FR particles, leading to:

♦ Better flame retardancy

♦ Moderate improvement in elongation at break

♦ Enhanced processing flow and molding stability

This confirms that SILIMER 6600 effectively upgrades both performance and processability in FR-based polymer systems.

Why Manufacturers Choose FR Masterbatches + Multi-Functional Dispersant SILIMER 6600

This combination gives manufacturers a tangible competitive advantage:

♦ Higher flame retardancy

♦ Stable mechanical properties

♦ Better production efficiency

♦ Reduced dosage and lower overall cost

Unlock Better FR Performance Through Better Dispersion

Flame retardant masterbatches blended with SILIMER 6600 offer a modern, efficient solution to enhance safety, processing, and material quality. As industry standards become increasingly stringent, optimizing dispersion is no longer optional—it’s essential.

Need Expert Guidance for Your Application?

SILIKE offers tailored recommendations for:

♦ Other multifunctional silicone additives for high-performance polymer systems

Whether you’re improving fiber flame resistance, developing safer electronics materials, or optimizing polyolefin formulations, our team can help you choose the right approach.

Contact Amy Wang at amy.wang@silike.cn or visit www.siliketech.com for flame retardant dispersion polymer processing additives solutions.

Post time: Nov-14-2025