Introduction: The Growing Demand for Efficient Heating Systems

As modern construction trends shift toward energy efficiency and sustainability, low-temperature radiant floor heating has become one of the fastest-growing heating solutions. It offers uniform heat distribution, improved comfort, space-saving installation, and long service life compared to traditional radiators.

Yet, one persistent technical challenge undermines performance: scaling inside floor heating pipes. Industry data indicates that more than 50% of systems experience scaling within 5–7 years, resulting in reduced heat transfer, higher energy consumption, and, in severe cases, partial blockages. For OEM pipe manufacturers and system engineers, this translates into higher maintenance requirements, dissatisfied customers, and reduced system efficiency.

The Problem: Why Do PE-RT and PE-X Pipes Scale Over Time?

Plastic pipes are widely used in radiant floor heating due to their flexibility, mechanical strength, impact resistance, and thermal stability. The most common materials include:

PE-RT (Polyethylene of Raised Temperature Resistance)

PE-X (Cross-linked Polyethylene, also referred to as XLPE)

PPR (Random Copolymerized Polypropylene)

PB (Polybutene)

Despite their popularity, these polymers share two critical weaknesses:

Low Thermal Conductivity → Poor heat transfer efficiency compared to metal pipes, increasing system energy demand.

Scaling on the Inner Surface → Mineral deposits and biofilm reduce effective pipe diameter, further lowering thermal efficiency and circulation.

Over time, the combined effect is 20–30% efficiency loss, higher operating costs, and premature pipe degradation. Traditional solutions such as chemical flushing or mechanical cleaning provide only temporary relief and may damage the pipe.

The Solution: Hydrophobic Inner Surfaces with SILIKE Silicone-Based Additives

A breakthrough approach lies in modifying the inner surface of PE-RT and PE-X pipes with SILIKE silicone-based polymer additives(Like, siliocne masterbatch LYSI-401 and Copolysiloxane Additive and Modifier SILIMER 66001G) during extrusion.

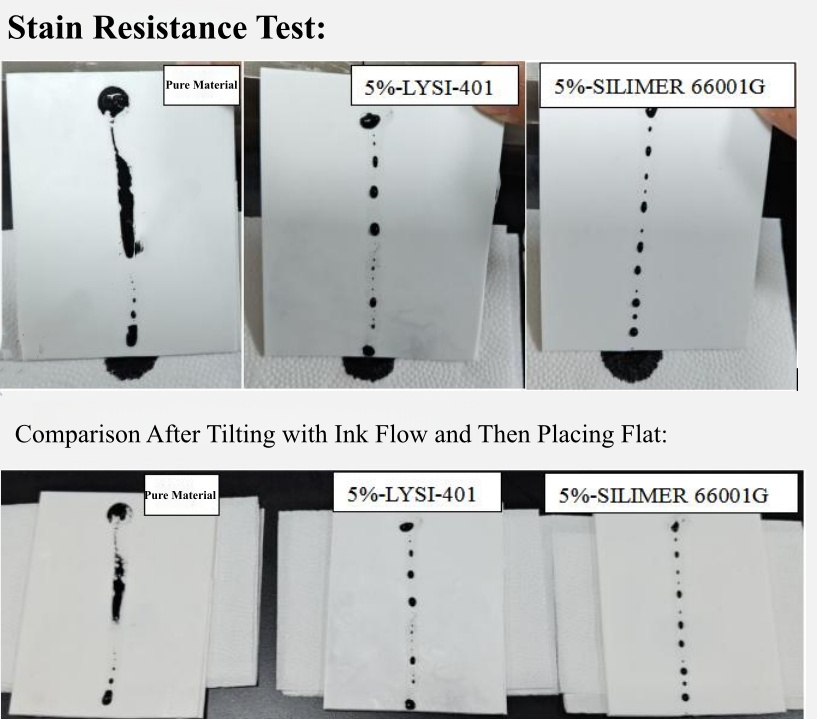

This creates a low-surface-energy, hydrophobic barrier that fundamentally reduces scale adhesion. Unlike coatings, the modification is intrinsic to the pipe material and does not wear off.

How does Hydrophobic Modification Work of Silicone Additives?

Low Surface Energy: Reduces mineral adhesion to the polymer wall.

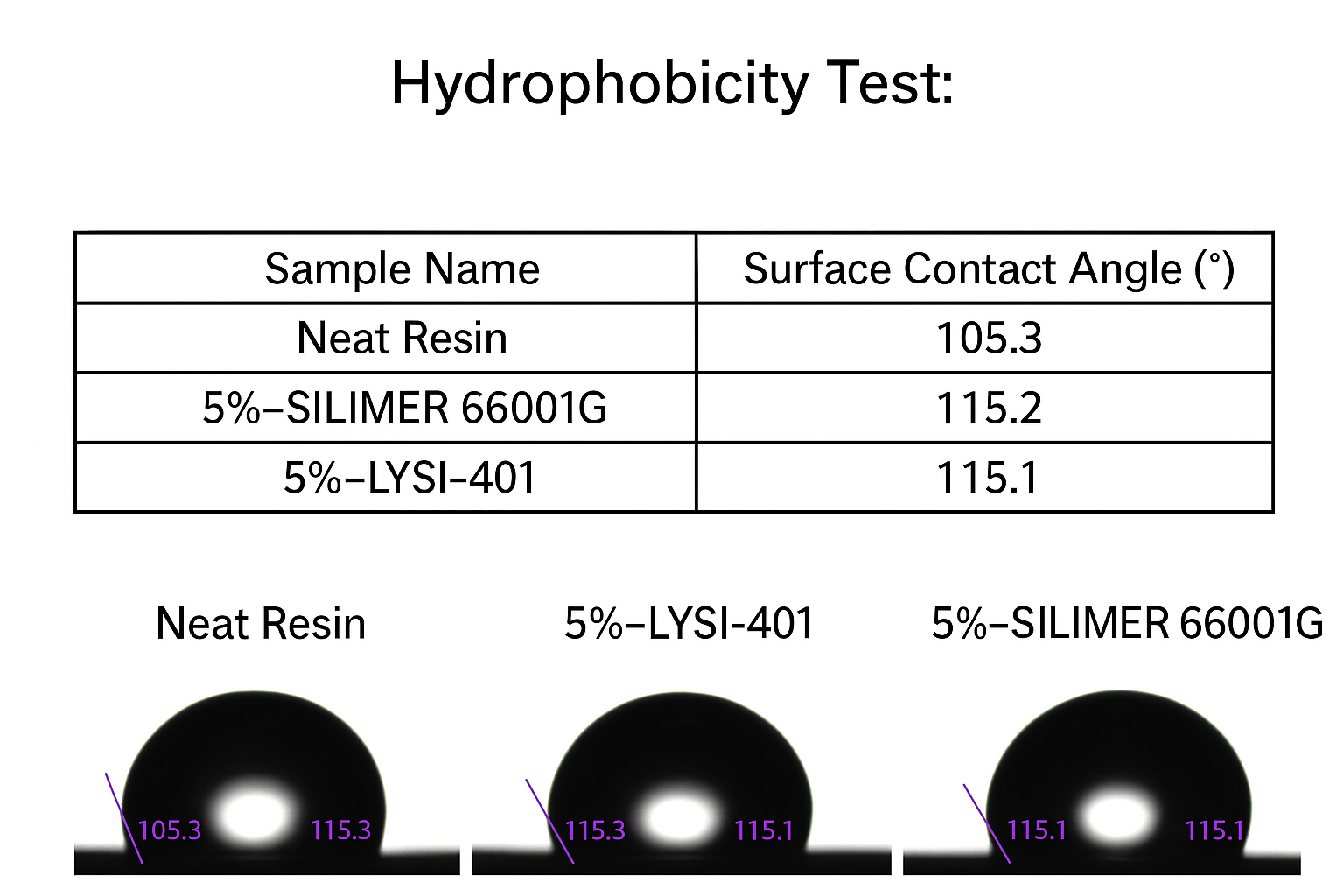

Hydrophobic Effect: Higher water contact angles prevent droplet residue and scaling.

Self-Smoothing Inner Layer: Provides a cleaner, long-lasting pipe surface.

• Superior Anti-Scaling Properties – Reduced mineral and biofilm deposits, maintaining stable flow.

• Improved Energy Efficiency – Consistent heat transfer performance, lower energy costs.

• Extended System Lifespan – Pipes retain design performance for longer heating cycles.

• Lower Maintenance Costs – Less need for chemical or mechanical cleaning.

• Eco-Friendly Solution – Reduced chemical cleaning aligns with green building standards.

• OEM Manufacturing Compatibility – Seamless integration into standard PERT and PE-X extrusion lines.

Applications and Benefits Across the Industry

• OEM Pipe Manufacturers: Differentiate products with built-in anti-scaling technology.

• Heating Contractors & System Designers: Deliver higher-performing systems with fewer long-term service issues.

• Homeowners & Building Managers: Ensure consistent comfort, reduced energy bills, and lower maintenance.

• Green Building & Sustainable Projects: Support energy conservation and environmental certifications.

Building Smarter, Cleaner Heating Systems

Scaling has long been an industry challenge in radiant floor heating, reducing both performance and system longevity. By integrating silicone-modified hydrophobic PE-RT and PE-X pipes, manufacturers can address the root cause—delivering pipes that remain cleaner, more efficient, and more reliable throughout their service life.

Looking to upgrade your Plastic pipes line with anti-scaling Hydrophobic technology?

Contact SILIKE to explore technical data on silicone-based plastic additives or to request samples at www.siliketech.com, or reach out directly to Amy Wang at amy.wang@silike.cn

Post time: Sep-11-2025