China Wholesale Surface Modifier Suppliers – Silicone Masterbatch LYSI-502C – Silike

China Wholesale Surface Modifier Suppliers – Silicone Masterbatch LYSI-502C – Silike Detail:

Description

Silicone Masterbatch ( Siloxane Masterbatch ) LYSI-502C is a pelletized formulation with a very high content of ultra high molecular weight siloxane polymer dispersed in ethylene-vinyl acetate copolymer (EVA ). It is widely used as an efficient additive in EVA compatible resin system to improve the processing properties and modify surface quality.

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing additives, SILIKE Silicone Masterbatch LYSI series are expected to give improved benefits, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

Fundamental Parameters

|

Grade |

LYSI-502C |

|

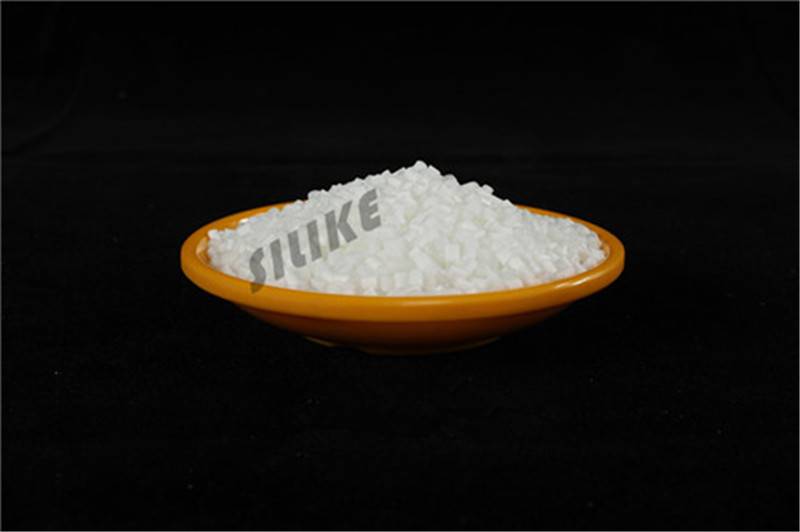

Appearance |

White pellet |

|

Carrier resin |

EVA |

|

MI(230℃, 2.16KG) g/10min |

2~4 |

|

Dosage% (w/w) |

0.5~5 |

Benefits

(1) Improve processing properties including better flow ability , reduced extrusion die drool , less extruder torque , better molding filling & release

(2) Improve surface quality like surface slip, lower Coefficient of friction, Greater abrasion & scratch resistance

(3) Faster throughput , reduce product defect rate.

(4) Enhance stability compare with traditional processing aid or lubricants

Applications

(1) HFFR / LSZH cable compounds

(2) EVA footwear

(3) Foamed EVA products

(4) Thermoplastic elastomers

(5) Other EVA compatible plastics

How to use

SILIKE LYSI series silicone masterbatch may be processed in the same way as the resin carrier on which they based. It can be used in classical melt blending process like Single /Twin screw extruder, injection molding. A physical blend with virgin polymer pellets is recommended .

Recommend dosage

When added to EVA or similar thermoplastic at 0.2 to 1% , improved processing and flow of the resin is expected, including better mold filling, less extruder torque, internal lubricants, mold release and faster throughput; At a higher addition level , 2~5%, improved surface properties are expected, including lubricity , slip, lower coefficient of friction and greater mar/scratch and abrasion resistance

Package

25Kg / bag , craft paper bag

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cn

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with China Wholesale Surface Modifier Suppliers – Silicone Masterbatch LYSI-502C – Silike , The product will supply to all over the world, such as: panama, Chile, America, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top