China Wholesale Silicone wax For Polyolefin Processing Factory – Flowable Silicone Wax SILIMER 5063 Processing Ease – Silike

China Wholesale Silicone wax For Polyolefin Processing Factory – Flowable Silicone Wax SILIMER 5063 Processing Ease – Silike Detail:

Description

SILIMER 5063 is long chain alkyl-modified siloxane masterbatch containing polar functional groups. It is mainly used in BOPP films, CPP films, pipes, pump dispensers and other products compatible with polypropylene. It can significantly improve anti-blocking & smoothness of the film, and the lubrication during processing, can greatly reduce the film surface dynamic and static friction coefficient, make the film surface more smooth. At the same time, SILIMER 5063 has a special structure with good compatibility with the matrix resin, no precipitation, no sticky, and no effect on the transparency of film.

Product Specifications

|

Grade |

SILIMER 5063 |

|

Appearance |

white or light yellow pellet |

|

Resin base |

PP |

|

Melt index (230℃, 2.16KG) g/10min |

5~25 |

|

Dosage % (w/w) |

0.5~5 |

Benefits

(1) Improve surface quality including no precipitation, no sticky, no effect on transparency, no effect on the surface and printing of film, lower Coefficient of friction, better surface smoothness.

(2)Improve processing properties including better flow ability, faster throughput.

Typical applications

(1) BOPP,CPP, and other PP compatible plastic films

(2)Pump dispensers, cosmetic covers

(3) Plastic pipe

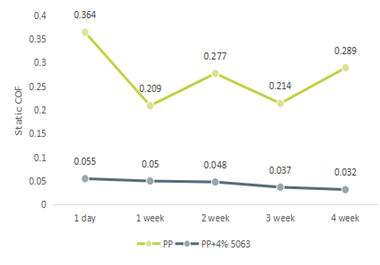

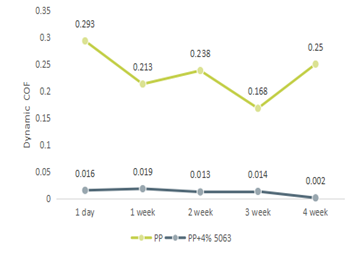

Typical COF test data ( Pure PP vs PP+ 4% 5063 )

How to use

Addition levels between 0.5~5.0% are suggested. It can be used in classical melt blending process like Single /Twin screw extruders, injection molding and side feed. A physical blend with virgin polymer pellets is recommended .

Transportation & Storage

This product could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with a storage temperature below 50 ° C to avoid agglomeration. The package must be well sealed after each use to prevent the product from being affected by moisture.

Package & Shelf life

The standard packaging is a craft paper bag with PE inner bag with net weight of 25kg . Original characteristics remain intact for 12 months from the production date if kept in recommend storage.

Marks: The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information cannot be understood as a commitment of this product. The raw materials and its composition of this product will not be introduced here because patented technology is involved.

Product detail pictures:

Related Product Guide:

Our progress depends around the innovative machines, great talents and consistently strengthened technology forces for China Wholesale Silicone wax For Polyolefin Processing Factory – Flowable Silicone Wax SILIMER 5063 Processing Ease – Silike , The product will supply to all over the world, such as: Slovakia, Belgium, Costa rica, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Phone

-

E-mail

-

WeChat

-

Top