China Wholesale Processing Additives For HFFR Compounds Factory – Anti-scratch Silicone Masterbatch LYSI-306C For Long-lasting Scratch Resistance of Automotive Interiors – Silike

China Wholesale Processing Additives For HFFR Compounds Factory – Anti-scratch Silicone Masterbatch LYSI-306C For Long-lasting Scratch Resistance of Automotive Interiors – Silike Detail:

Description

Silicone masterbatch LYSI-306C is an upgraded version of LYSI-306, has an enhanced compatibility with the Polypropylene (CO-PP ) matrix — Resulting in lower phase segregation of the final surface, this means it stays on the surface of the final plastics without any migration or exudation , reducing fogging , VOCS or Odors . LYSI-306C helps improve long-lasting anti-scratch properties of automotive interiors , by offering improvements in many aspects like Quality, Aging , Hand feel, Reduced dust buildup… etc. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels.

Fundamental Parameters

|

Grade |

LYSI-306C |

|

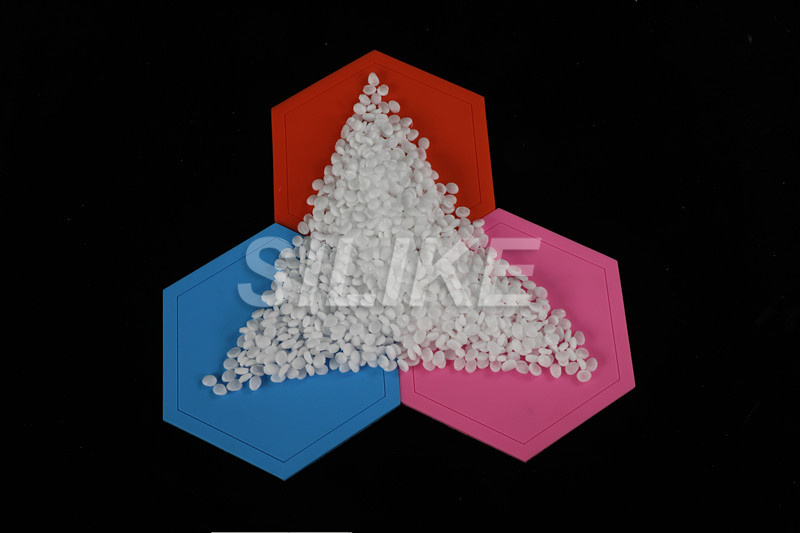

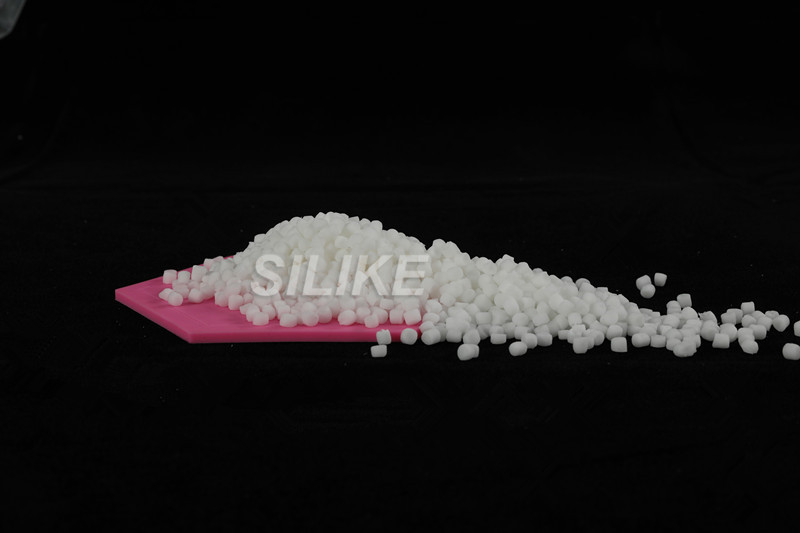

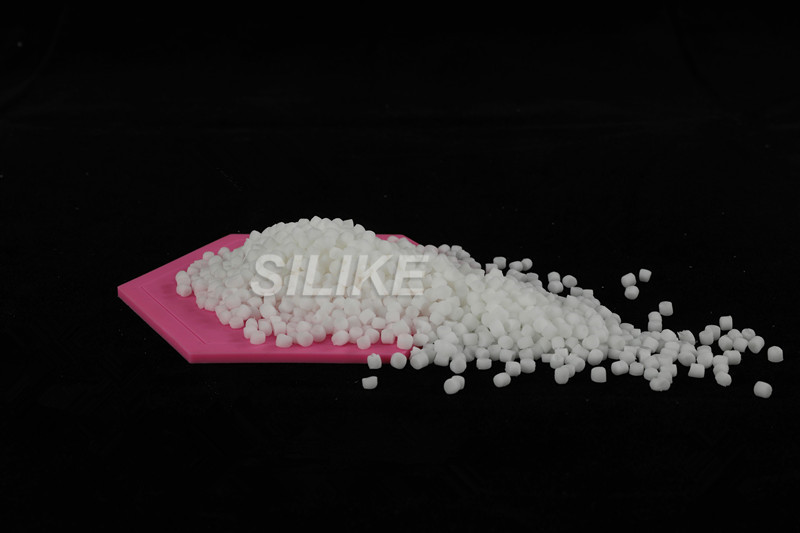

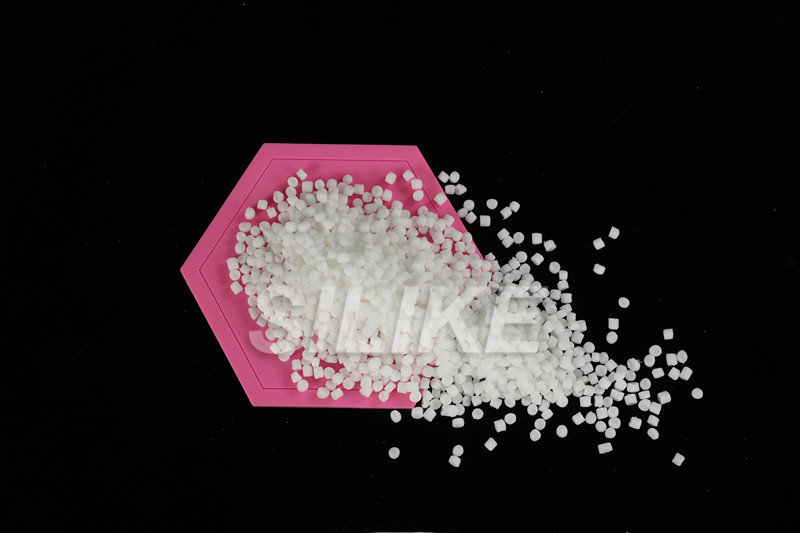

Appearance |

White pellet |

|

Silicone content % |

50 |

|

Resin base |

PP |

|

Melt index ( 230℃, 2.16KG ) g/10min |

2 ( typical value ) |

|

Dosage% (w/w) |

1.5~5 |

Benefits

Silicone masterbatch LYSI-306C serves as both an anti-scratch surface agent and a processing aid . This offers controlled and consistent products as well as a tailor-made morphology.

(1) Improves the anti-scratch properties of TPE,TPV PP,PP/PPO Talc filled systems.

(2) Operates as a permanent slip enhancer

(3) No migration

(4) Low VOC emission

How to use

Addition levels between 0.5~5.0% are suggested . It can be used in classical melt blending process like Single /Twin screw extruders, injection molding. A physical blend with virgin polymer pellets is recommended .

Package

25Kg / bag , craft paper bag

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for China Wholesale Processing Additives For HFFR Compounds Factory – Anti-scratch Silicone Masterbatch LYSI-306C For Long-lasting Scratch Resistance of Automotive Interiors – Silike , The product will supply to all over the world, such as: South Korea, Tunisia, Hyderabad, In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always offer customers support on products and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top