Solve PP/TPO Scratch Problems in Automotive Interiors – With Proven Scratch Resistance Solutions

Boost Durability, Aesthetics, and VOC Compliance with SILIKE Anti-Scratch Masterbatch

In automotive interiors, appearance is a critical driver of perceived vehicle quality. Scratches, marring, and gloss changes on high-touch components—such as dashboards, door trims, center consoles, and pillar covers—directly influence customer satisfaction and brand perception.

Thermoplastic polyolefins (TPOs) and talc-filled polypropylene (PP) compounds are widely used for interior components due to their lightweight nature, cost efficiency, and design flexibility. However, these materials inherently exhibit poor scratch and mar resistance, especially under high-wear conditions. Traditional solutions—including waxes, slip agents, coatings, and nano-fillers—often fail to deliver stable long-term performance and tend to introduce undesirable side effects such as migration, uneven gloss, fogging, odors, or increased VOC emissions, all of which conflict with increasingly strict OEM requirements.

Since 2013, SILIKE has been dedicated to the automotive interior market, advancing silicone-modification technology to develop high-performance anti-scratch solutions. Over the past decade, our silicone-based masterbatches have earned the trust of leading OEMs and Tier-1 suppliers for their proven ability to enhance surface durability while maintaining premium aesthetics, low VOC emissions, and long-lasting resistance without migration or exudation stickiness, yellowing, or stress-whitening.

Our Anti-Scratch Masterbatch Series has evolved through multiple stages of R&D to meet ever-tightening performance standards and industry trends. With SILIKE’s solutions, automotive manufacturers can confidently upgrade interior durability while preserving the premium look and feel of high-touch surfaces—fully aligning with aesthetic expectations, OEM specifications, and regulatory requirements.

For producers of PP, TPO, TPV compounds, and other modified composite materials, SILIKE Anti-Scratch Masterbatch offers a high-efficiency, cost-effective, and OEM-compliant solution to significantly improve scratch and mar resistance. It achieves this without compromising appearance or mechanical properties, while maintaining excellent thermal and UV stability to prevent yellowing, stickiness, or stress-whitening associated with conventional additives. In addition, these solutions help reduce emissions and odors, deliver a better tactile feel, and minimize dust accumulation — improving cabin air quality and supporting environmental compliance.

These anti-scratch additives improve both the processing performance of plastic compounds and the surface quality of finished components across automotive interiors—including glossy, fine-grain, and coarse-grain surfaces—and are effective for both dark and light-colored parts requiring higher scratch resistance. They are also suitable for home appliance housings, decorative panels, sheets, and sealing strips.

The SILIKE Anti - Scratch Masterbatch Series is suitable for a wide range of polymer compounds. It can enhance the processing performance and modify the surface characteristics of finished components in automotive interiors and other applications that require scratch resistance. Typical applications include:

● PP (Polypropylene)

● TPO (Thermoplastic Polyolefins)

● PP/TPO talc-filled systems

● TPE (Thermoplastic Elastomers)

● TPV (Thermoplastic Vulcanizates)

● PC (Polycarbonate)

● ABS (Acrylonitrile Butadiene Styrene)

● PC/ABS blends

● Other modified thermoplastic materials

Performance Additives of Choice for PP, TPO, TPV Compounds and Other Modified Thermoplastic Materials

Based on client feedback, the most widely adopted products from the SILIKE Anti-Scratch Masterbatch Series—recognized for their innovative, low-VOC, and long-lasting scratch-resistance performance—include:

LYSI-306 – Anti-Scratch Additive for PP, TPO & Talc-Filled Compounds – Prevent Scratches, Mar, and Abrasion in Automotive Interiors

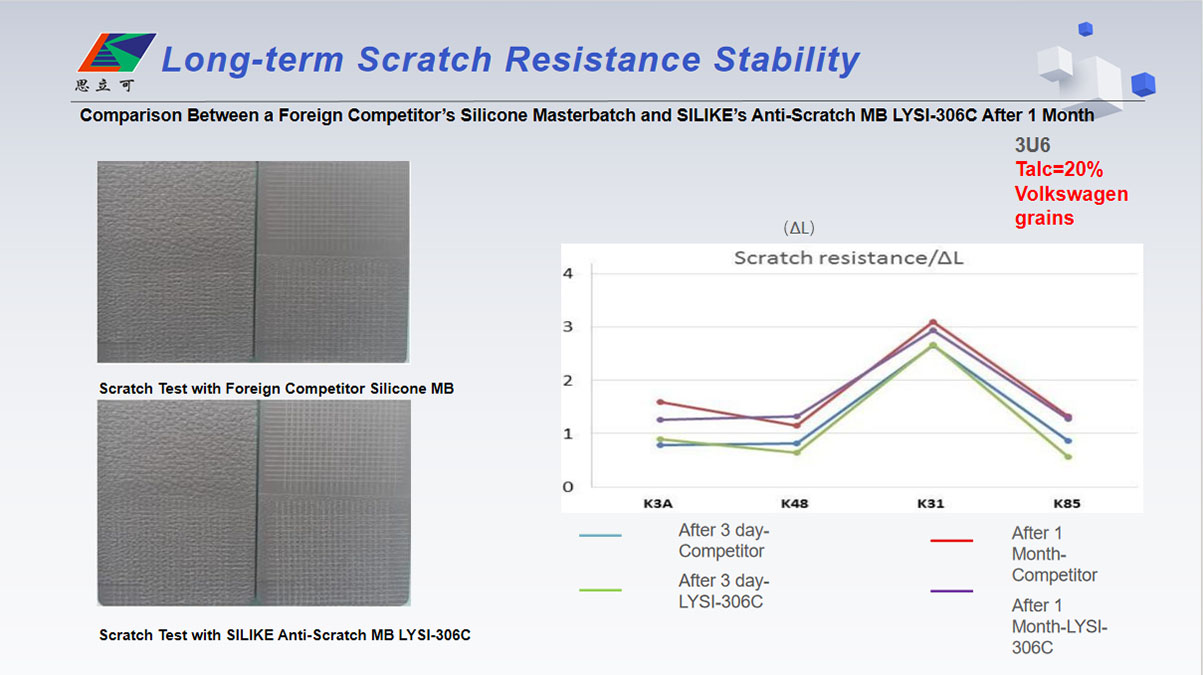

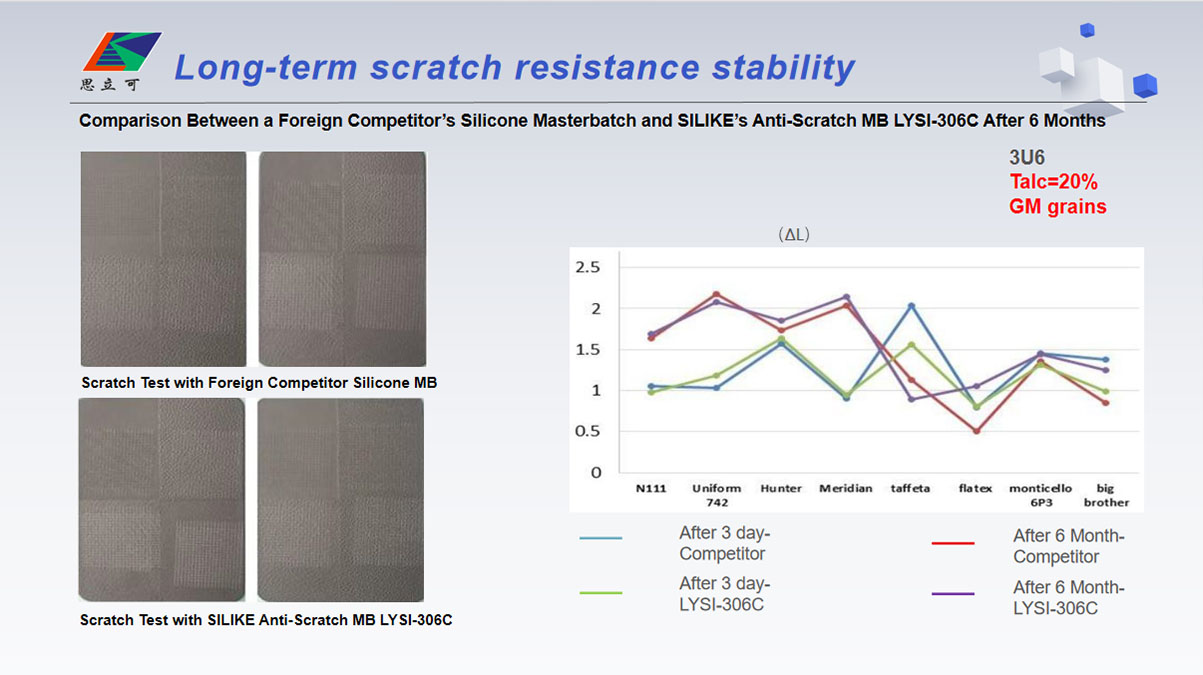

LYSI-306C – Long-Term Scratch Resistance Additive for PP/TPO Systems – OEM-Compliant Solution for Automotive Door Panels

LYSI-306H – High Scratch Resistance Silicone Masterbatch for Thermoplastic Compounds – Durable Surfaces for Instrument Panels and High-Wear Interiors

LYSI-306G – Next-Generation Anti-Scratch Solution for PP Compounds – Non-Migrating, Non-Sticky, High-Temperature Stable Additive

LYSI-906 – Ultra-Low VOC, Non-Tacky Anti-Scratch Additive for PP, TPO & TPV Automotive Interiors – Long-Lasting Scratch Resistance for High-Touch Surfaces

LYSI-301 – Anti-Scratch Lubricant Additive for PE & TPE Compounds – Improve Surface Quality, Reduce Friction, and Enhance Mar and Abrasion Resistance

LYSI-405 – Anti-Scratch Processing Aid for PC & ABS – Long-Lasting Surface Protection for Consumer Electronics and Automotive Interiors

LYSI-4051 – Matte PC/ABS Anti-Scratch Silicone Masterbatch – Reduce Visible Scratches and Stress Whitening on Low-Gloss Surfaces

LYSI-413 – Anti-Scratch Plastic Additive with High Abrasion and Mar Resistance for PC in Automotive Interiors and Electronic Components

Why Choose SILIKE’s Anti-Scratch Additives – Premium, Long-Lasting Protection for Automotive and Industrial Polymers

Core Performance Advantages

• Permanent Scratch Resistance: Acts as a durable slip enhancer to prevent scratches, mar, and visible whitening on high-touch surfaces.

• Enhanced Tactile Quality: Provides a soft-touch, premium hand feel for an elevated user experience.

• Low Friction & Smooth Surface Interaction: Reduces wear and dust accumulation while ensuring consistent performance on complex designs with fine textures or soft-touch finishes.

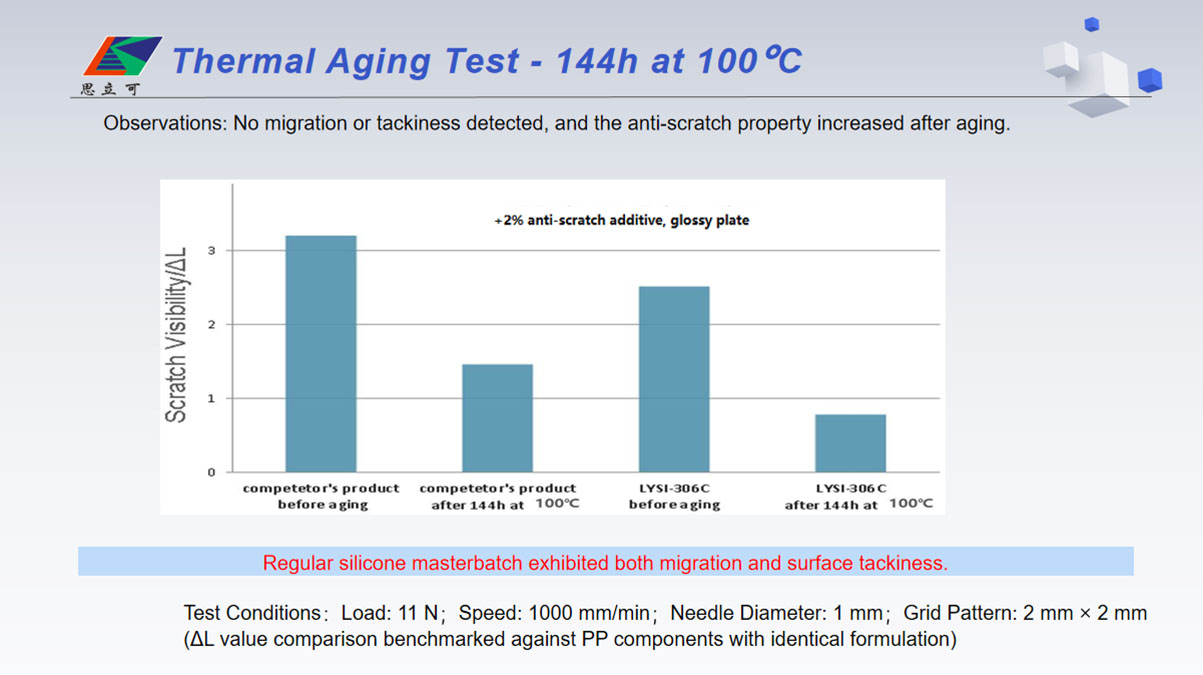

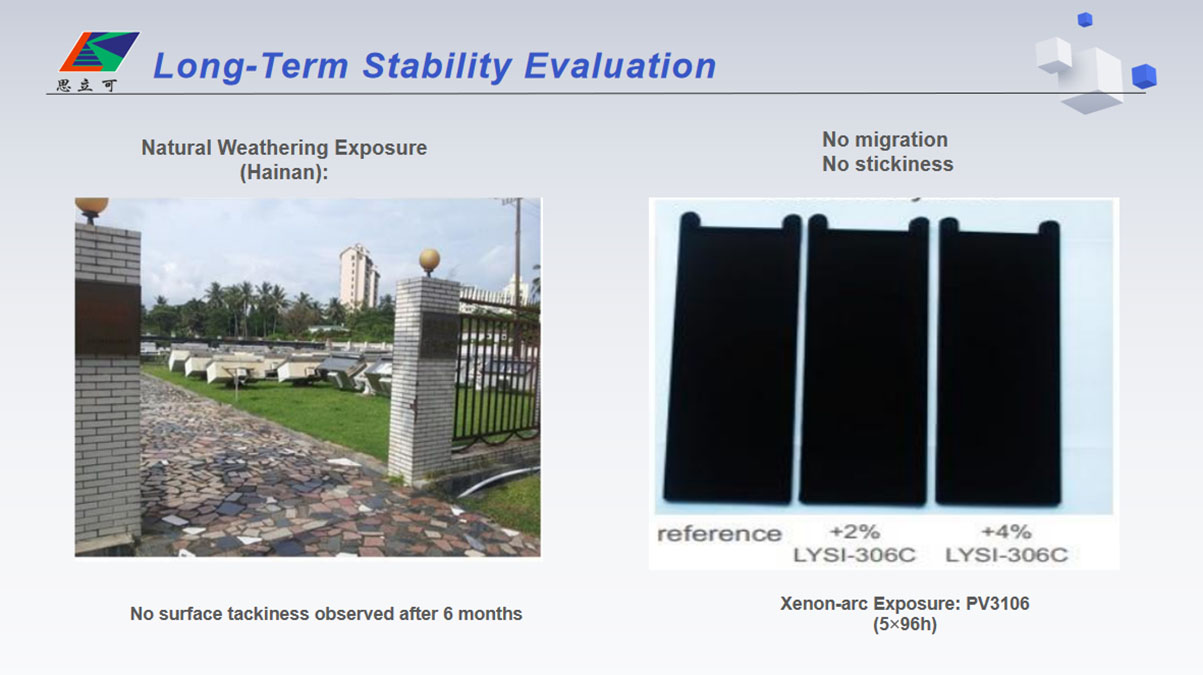

• Stable, Non-Migrating Performance: No tackiness, precipitation, or plate-out during molding, extrusion, or long-term aging, as verified by accelerated lab tests and natural weathering.

• Gloss Retention: Maintains pristine surface appearance even after repeated contact or abrasion, and supports streak-free automotive interiors.

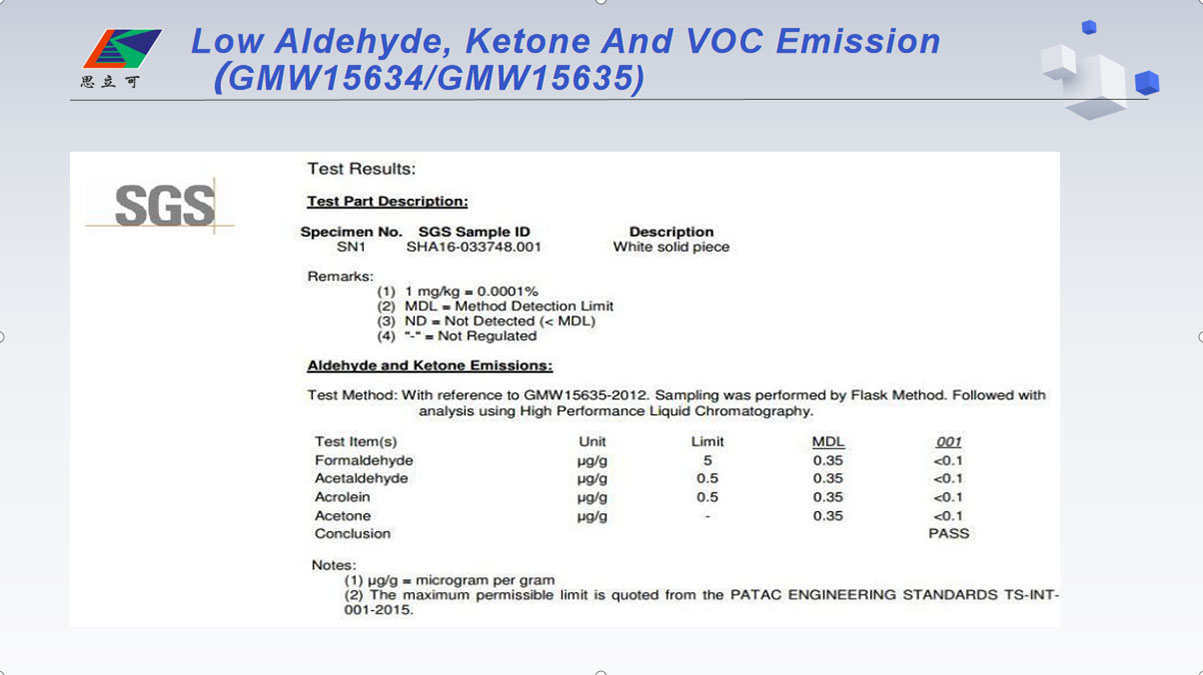

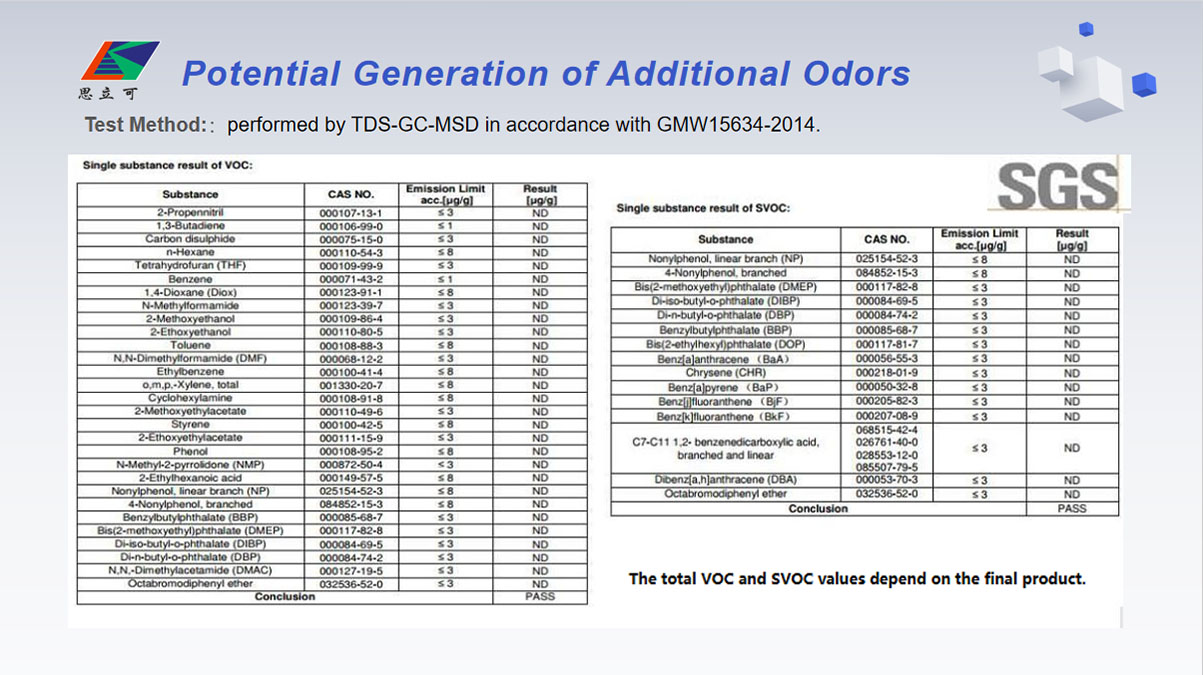

• Environmentally Compliant: Low-VOC and low-odor formulation meets global automotive and environmental standards.

Certifications & OEM Compliance:

✔ Silicone anti-scratch masterbatches comply with Volkswagen PV3952 and GM GMW14688 standards.

✔ Comply with Volkswagen PV1306 (96X5) — no migration or tackiness.

✔ Passed natural weathering exposure tests (Hainan) — no stickiness after 6 months.

✔ VOC emissions testing passed GMW15634-2014.

✔ All silicone scratch resistance additives comply with RoHS and REACH standards.

Trusted by Leading OEMs and Tier-1 Suppliers: SILIKE anti-scratch additives enhance surface durability, extend service life, and maintain premium quality across demanding polymer applications, including automotive interiors, electronics, and consumer goods.

Case Studies & Product Applications

Proven Results Across Global Polymer Compounding and Automotive Manufacturing

Anti-Scratch Agent LYSI-306 for Polypropylene-Compatible Systems

At 0.2%–2.0% addition, LYSI-306 enhances PP and similar thermoplastics by improving melt flow, mold filling, internal lubrication, mold release, and overall extrusion efficiency—reducing extruder torque and increasing throughput.

At higher concentrations (2%–5%), it delivers superior surface performance, including:

• Enhanced lubricity and slip

• Lower coefficient of friction

• Improved scratch, mar, and abrasion resistance

Performance Highlights:

• Increases throughput and reduces energy consumption

• Provides longer-lasting surface durability than traditional processing aids and lubricants

• Performance-equivalent to MB50-001

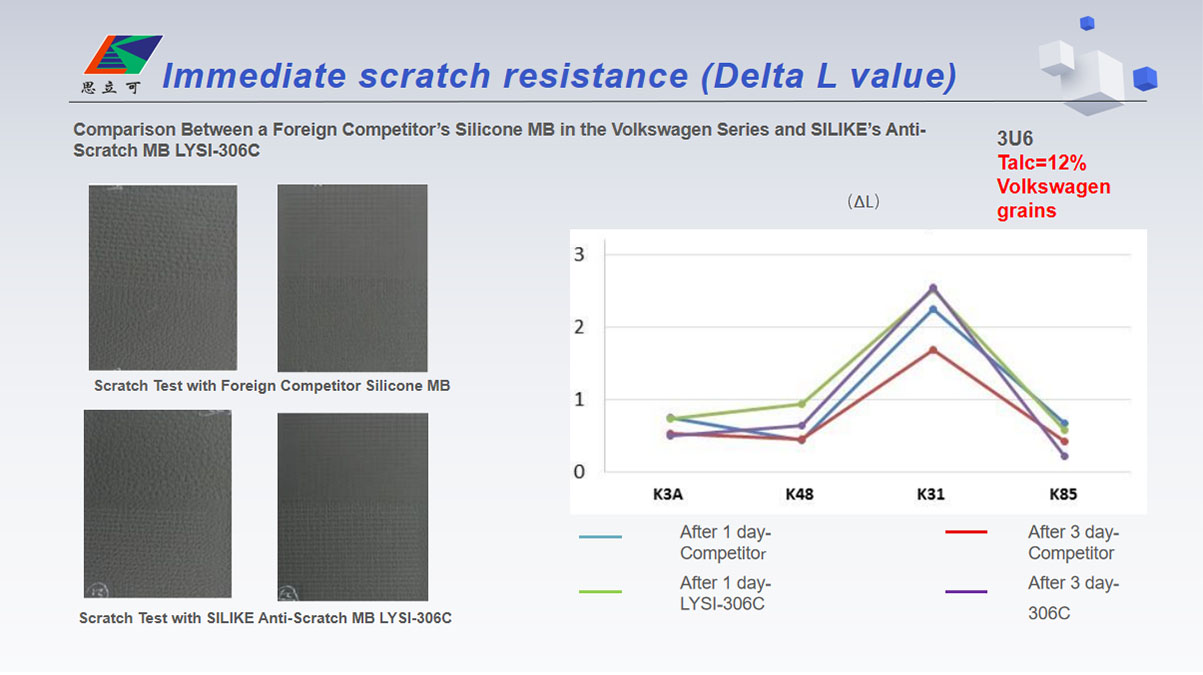

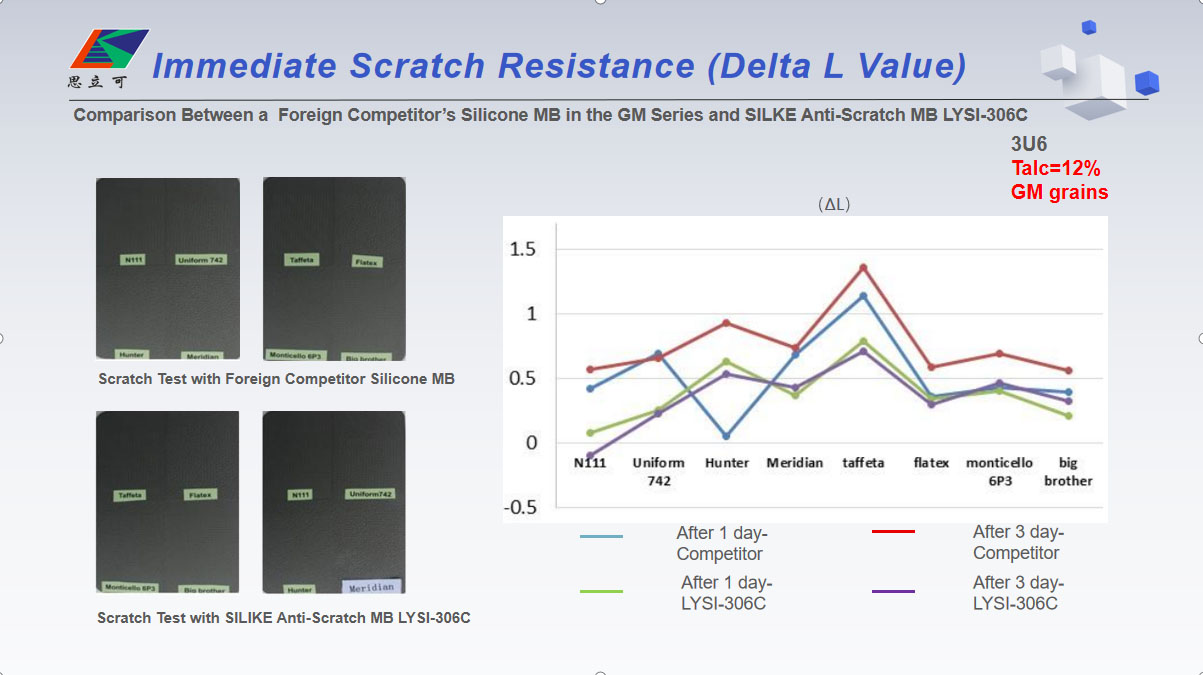

LYSI-306C – Long-Term Scratch Resistant Additive for PP/TPO Compounds

LYSI-306C is an upgraded version of LYSI-306, engineered for long-lasting scratch resistance in PP/TPO systems.

Key Benefits:

• 1.5% addition meets VW PV3952 and GM GMW14688 scratch performance standards

• ΔL < 1.5 under 10 N load

• Non-sticky, low VOCs, no surface haze

• Designed as a replacement for MB50-0221

LYSI-306H – High Scratch Resistance Solution for TPO Compounds

LYSI-306H offers significantly enhanced scratch resistance compared with LYSI-306 and competitive solutions. Optimized for HO-PP–based TPO systems, it provides:

• Improved compatibility with HO-PP matrix

• Minimal phase segregation on final surfaces

• Non-migrating and non-exuding performance under UV and thermal aging

• ΔL < 1.5 at <1.5% addition

• Replacement for MB50-001G2

LYSI-306G – High-Performance Anti-Scratch Additive for Modified Plastics

LYSI-306G is a new-generation additive designed to overcome the limitations of traditional lubricants, silicone oils, and low molecular weight slip agents.

Benefits:

• Non-migrating, non-sticky, thermally stable

• Maintains premium surface durability

• Provides long-lasting scratch resistance in PP compounds

LYSI-906 – Low-VOC, Non-Precipitating Anti-Scratch Additive for Specialty & Engineering Polymers

LYSI-906 is a next-generation functional additive engineered for high-performance, long-term scratch resistance in PP/TPO/TPV materials.

Key Features:

• Exceptional scratch resistance and thermal stability

• Strong non-migration performance

• Ultra-low odor and VOC emissions

• Non-tacky; no precipitation at elevated temperatures

• Maintains surface quality under high-touch, high-wear conditions

• Improves in-cabin air quality and environmental safety

LYSI-301 – Efficient PE/TPE Surface Modifier

LYSI-301 is an effective performance additive for PE-compatible systems, improving processing properties and surface quality.

Performance Improvements:

• Enhanced resin flow, mold filling, and release

• Reduced extruder torque

• Lower coefficient of friction

• Increased mar and abrasion resistance

LYSI-405 – High-Performance Scratch Resistance for ABS

Benefits:

• Provides long-lasting scratch resistance

• Reduces everyday scratches and marring

• Improves surface smoothness and visual quality

• Facilitates component assembly and insertion

LYSI-4051 – Anti-Scratch Solution for PC/ABS and PMMA

LYSI-4051 contains ultra-high molecular weight siloxane with functional groups, offering:

Excellent scratch resistance

• Reduced stress whitening and visible scratches

• Non-migrating, stable long-term performance

• Improved mold release, reduced torque, and better tactile quality

Highlights:

• Ideal for high-gloss and matte ABS/PC/ABS applications

• Enhances the visual distinctiveness of home appliances, automotive interiors, and consumer electronics

• Expands processing flexibility for ABS components

LYSI-413 – High-Durability PC Anti-Scratch Additive

Designed for highly wear-resistant and scratch-resistant PC applications, LYSI-413 provides:

• Improved flow, mold release, and surface smoothness

• Reduced friction coefficient

• Enhanced abrasion and scratch resistance

• Minimal impact on mechanical properties

Relevant Performance Test Evaluations

Take a Look at How Our Clients Benefit From SILIKE Anti-Scratch Masterbatch Products

★★★★★

Durable Scratch Resistance in Automotive Talc-filled PP/ /TPO Compounds

"Since we started using LYSI-306, scratches and mar on our door panels have dropped dramatically. The surfaces stay pristine, and our production runs much smoother."

— Rajesh Kumar, Senior Process Engineer, Polymer Compounds

★★★★★

Long-Term Scratch Resistance for PP/TPO

"LYSI-306C helped our formulations pass OEM scratch tests with very low additive load. Surfaces hold up even under heavy use, and we didn’t see any tackiness or extra VOCs."

— Claudia Müller, R&D Manager, Composite Materials Producer

★★★★★

High Scratch Resistance for Polymer Compounds

"Using LYSI-306H in modified thermoplastic materials to manufacture instrument panels, our customers have reported that the panels no longer exhibit phase separation or sticky defects. Even under heat and UV exposure, color change is minimal, and the surfaces remain smooth."

— Luca Rossi, Production Lead, Modified Thermoplastic

★★★★★

High-Temperature Stable Next-Gen Anti-Scratch for PP

"Traditional slip agents would migrate during high-temperature extrusion, but LYSI-306G keeps surfaces consistent. Our interior lines now run reliably with premium finishes."

— Emily Johnson, Senior Compounder, Interior Materials

★★★★★

Ultra-Low VOC, Non-Tacky PP/TPO/TPV

"Dashboards and center consoles look great after using LYSI-906. Surfaces stay glossy without any tackiness, and we meet strict VOC standards effortlessly."

— Lyndon C., Materials Engineer, OEM

★★★★★

Enhancing Surface Durability in TPE EV Charging Cables

"After adding SILIKE LYSI-301 to our TPE charging-pile cable formulation, surface abrasion during extrusion dropped noticeably, and the cable maintained a more uniform finish."

"Unlike other additives we tested, LYSI-301 showed no migration and did not alter mechanical l performance."

— Lukito Hadisaputra, Product Development Manager, Plastic Components

★★★★★

Enhancing Surface Quality and Processing Efficiency for ABS Compounds

"During high-volume production of ABS housings, minor drag marks, scratches, and sticking during demolding were common—slowing production and increasing rework."

"Finding an additive that improved scratch resistance without compromising mold release was critical. Many solutions addressed one issue but caused new problems."

"LYSI-405 delivered both. Surface durability improved significantly, demolding became smoother, and sticking points were greatly reduced. Even tool cleaning intervals were extended, minimizing downtime."

"Thanks to LYSI-405, our assembly line now operates more efficiently, and surface quality is consistent across batches—helping us meet tight automotive electronics production standards."

— Andreas Weber, Process Engineer, Automotive Electronics

★★★★★

Enhancing Scratch Resistance and Processing Efficiency for PC/ABS Compounds

"Anyone working with matte PC/ABS knows how sensitive the surface can be. Even light rubbing may cause shiny spots, stress whitening, or shallow scratches that do not recover—an ongoing issue in high-volume production."

"Many additives we previously tested either changed the matte appearance, migrated, or introduced stickiness. We needed a solution that could protect the surface texture without altering the visual finish."

"LYSI-4051 significantly improved processing efficiency, reduced visible scratches, and eliminated whitening, all while preserving the original surface appearance."

— Sophie Green, Materials Engineer, Specialty & Engineering Polymers

★★★★★

High Abrasion and Scratch Resistance for PC

"PC components now handle scratches, wear, and tear much better. LYSI-413 reduces visible mar and shear marks, keeping both functionality and clarity intact."

— Marcin Taraszkiewicz, Performance Polymers Specialist

Say goodbye to scratches and surface defects — elevate the durability, processing efficiency, and appearance of your plastic components with SILIKE Anti-Scratch Solutions.