Anti-Abrasion Masterbatch NM-3 for rubber footwear

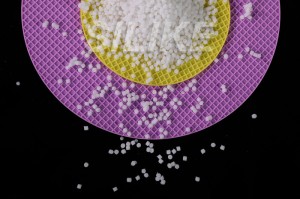

SILIKE Anti-abrasion masterbatch NM-3 is a pelletized additive containing 50% active ingredient dispersed in a styrene-butadiene block copolymer (SBS) carrier.

Compared with traditional low-molecular-weight silicone/siloxane additives—such as silicone oil, silicone fluids, or common anti-wear agents—SILIKE NM-3 provides:

• More durable and long-lasting abrasion resistance

• Better compatibility with SBS-based formulations

• No migration or blooming risk

• Stable color and mechanical properties

|

Grade |

NM-3 |

|

Appearance |

White pellet |

|

active ingredients content % |

50 |

|

Carrier |

SBS |

|

Melt index ( 190℃, 10.00KG ) g/10min |

4.50 ( typical value ) |

|

Dosage % (w/w) |

0.5~5% |

(1) Improved abrasion resistance with decreased abrasion value

(2) Impart the processing performance and final items appearance

(3) Eco-friendly

(4) No influence on hardness and color

(5) Effective for DIN, ASTM, NBS , AKRON, SATRA, GB abrasion tests

.....

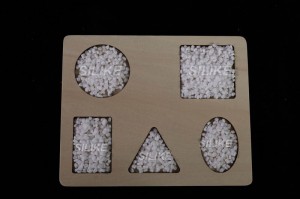

Applicable for the color rubber shoe’s sole compounds

Mix NM-3 with rubber into internal mixer during the temperature rising mixture process, to evenly mix. The output temperature should be above 100 ℃.

When added to rubber at 0.2 to 1% , improved processing and flow of the resin is expected, including better mold filling, less extruder torque, internal lubricants, mold release and faster throughput; At a higher addition level , 2~10%, improved surface properties are expected, including lubricity , slip, lower coefficient of friction and greater mar/scratch and abrasion resistance

25Kg / bag , craft paper bag

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cn

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top